Subaru Legacy IV (2008 year). Manual - part 73

ME(H4SO)-88

Cylinder Block

MECHANICAL

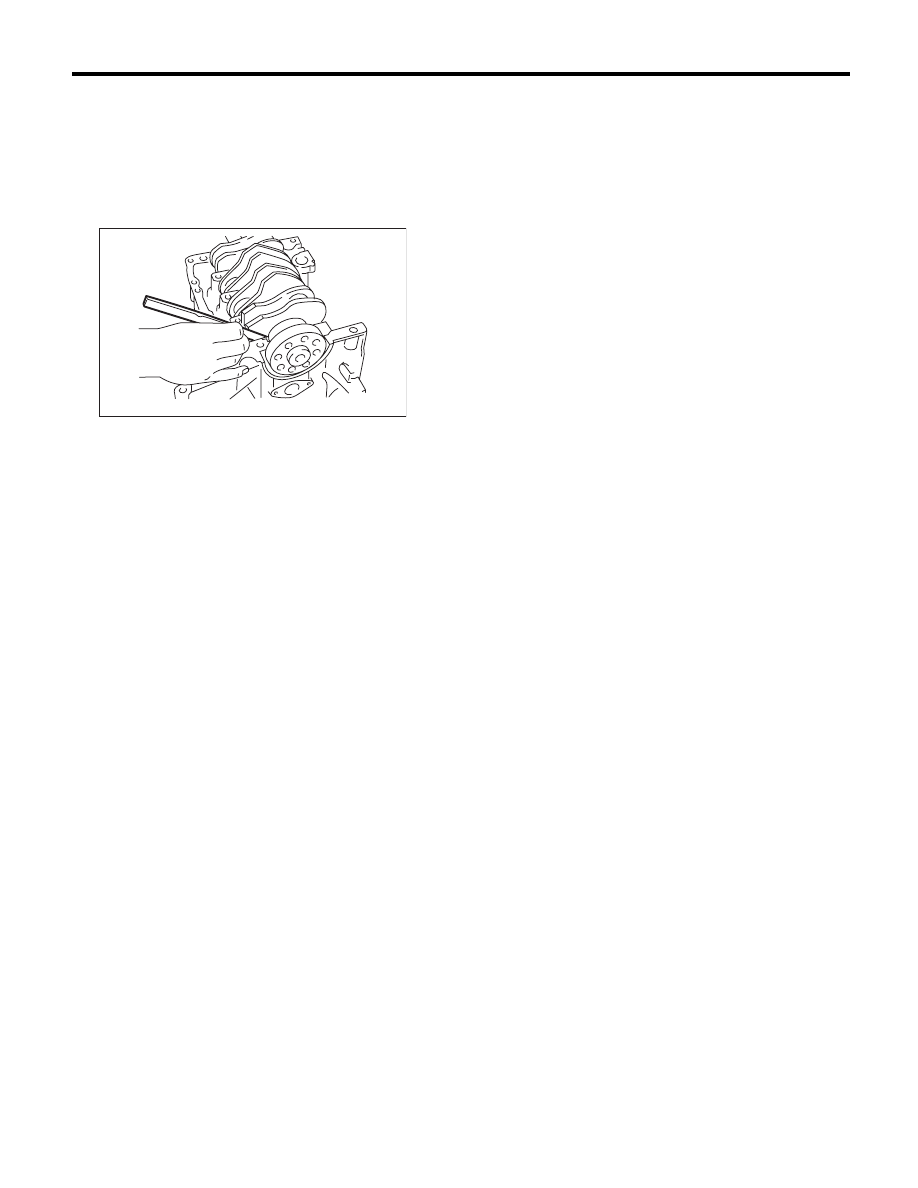

4) Use a thickness gauge to measure the thrust

clearance of crankshaft at #5 crank journal bearing.

If the thrust clearance is not within the standard, re-

place the bearing.

Crankshaft thrust clearance:

Standard

0.030 — 0.115 mm (0.0012 — 0.0045 in)

5) Inspect individual crankshaft bearings for signs

of flaking, seizure, melting and wear.

6) Measure the oil clearance on each crankshaft

bearing using plastigauge. If the measured value is

out of standard, replace the defective bearing with

an undersize one, and replace or grind to correct

the crankshaft as necessary.

Crankshaft oil clearance:

Standard

0.010 — 0.030 mm (0.0004 — 0.0012 in)

ME-00322