Subaru Legacy IV (2008 year). Manual - part 71

ME(H4SO)-80

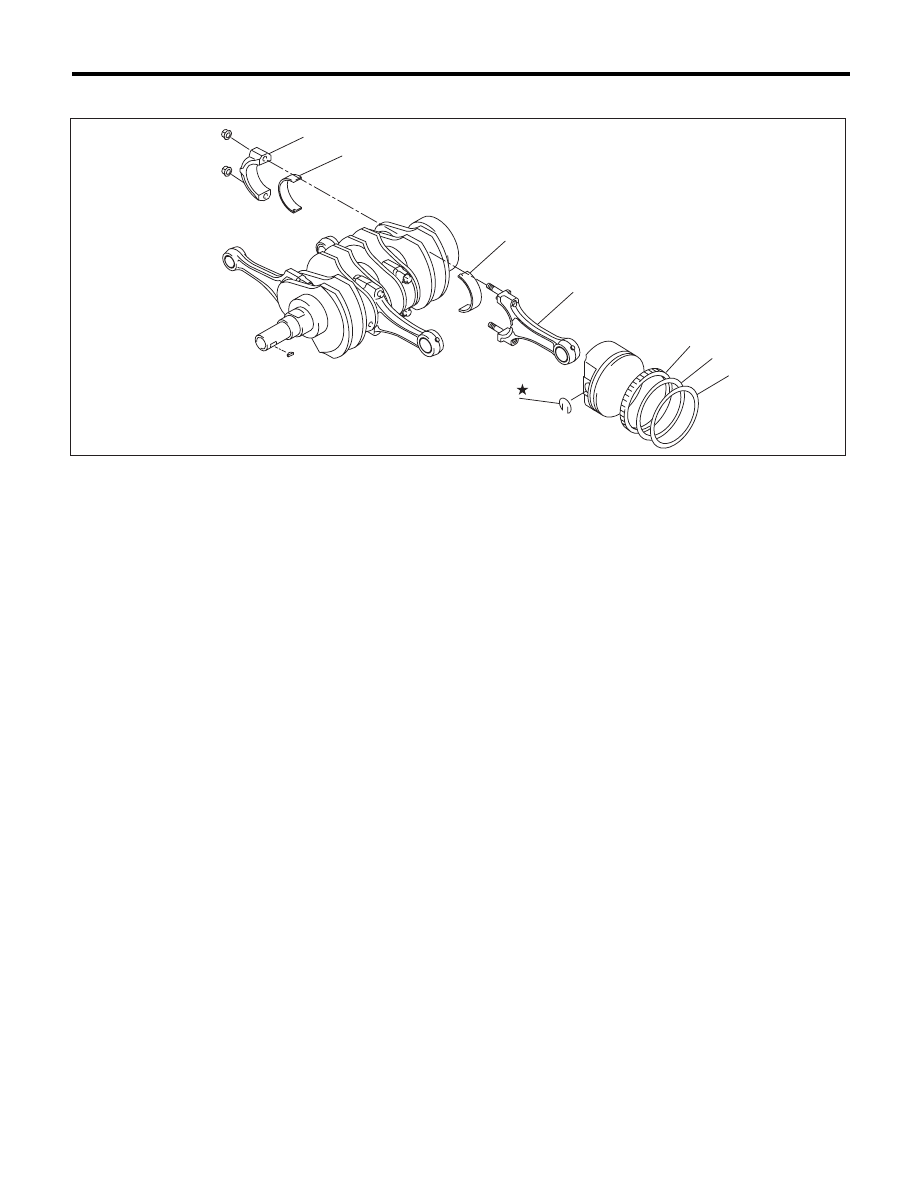

Cylinder Block

MECHANICAL

C: DISASSEMBLY

1) Remove the connecting rod cap.

2) Remove the connecting rod bearing.

NOTE:

Keep the removed connecting rods, connecting rod

caps and bearings in order so that they are kept in

their original combinations/groups, and not mixed

together.

3) Remove the piston rings using piston ring ex-

pander.

4) Remove the oil ring by hand.

NOTE:

Arrange the removed piston rings in proper order,

to prevent confusion.

5) Remove the snap ring.

(1)

Connecting rod cap

(4)

Second ring

(6)

Snap ring

(2)

Connecting rod bearing

(5)

Oil ring

(7)

Connecting rod

(3)

Top

ring

ME-03562

(2)

(2)

(6)

(5)

(4)

(3)

(1)

(7)