Subaru Legacy IV (2008 year). Manual - part 70

ME(H4SO)-76

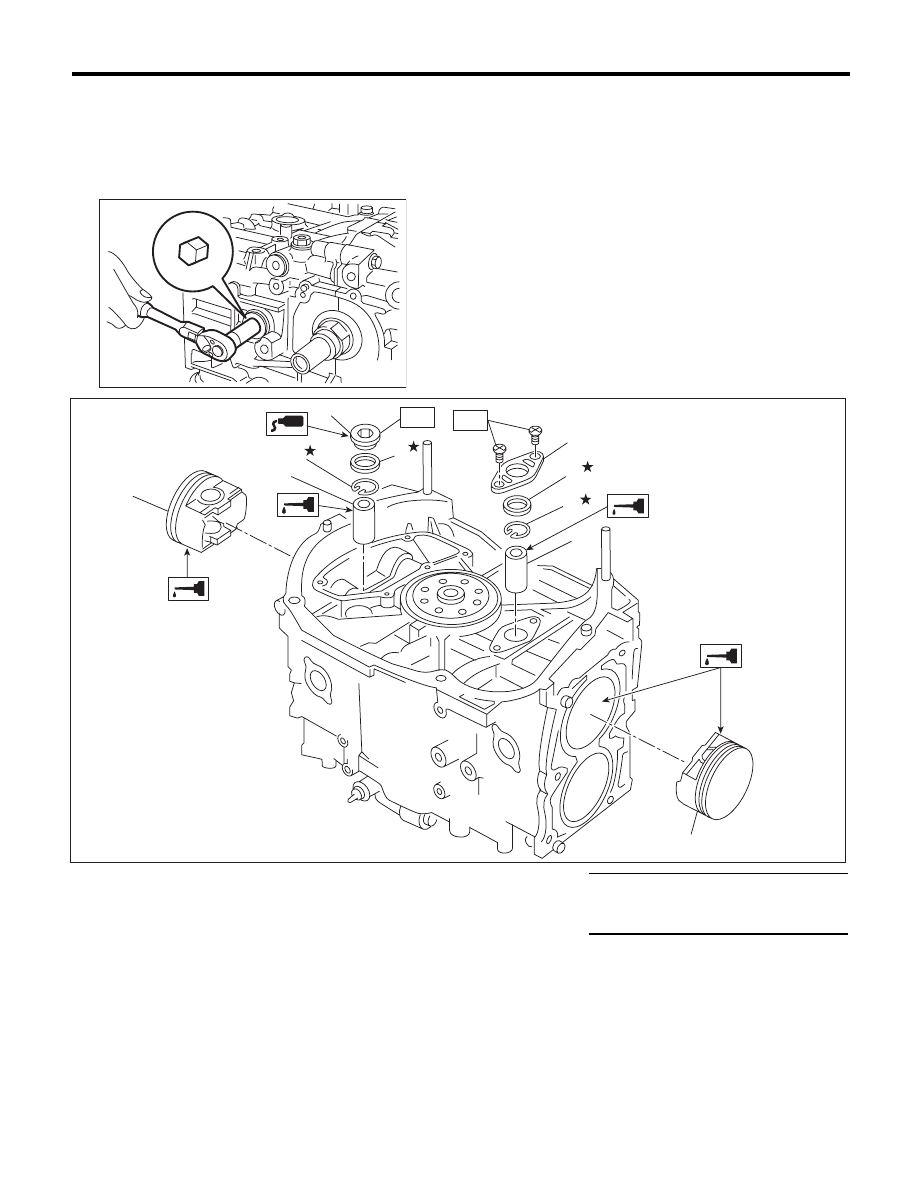

Cylinder Block

MECHANICAL

(6) Install the service hole plug and gasket.

NOTE:

Use a new gasket.

Tightening torque:

70 N·m (7.1 kgf-m, 51.6 ft-lb)

ME-00140

(1)

Piston

(5)

Service hole plug

Tightening torque:N·m (kgf-m, ft-lb)

(2)

Piston pin

(6)

Service hole cover

T1: 6.4 (0.7, 4.7)

(3)

Snap ring

(7)

O-ring

T2: 70 (7.1, 51.6)

(4)

Gasket

(2)

(3)

(1)

(2)

(6)

(3)

(7)

(4)

(5)

ME-02440

T2

T1

(1)