Subaru Legacy IV (2008 year). Manual - part 61

ME(H4SO)-40

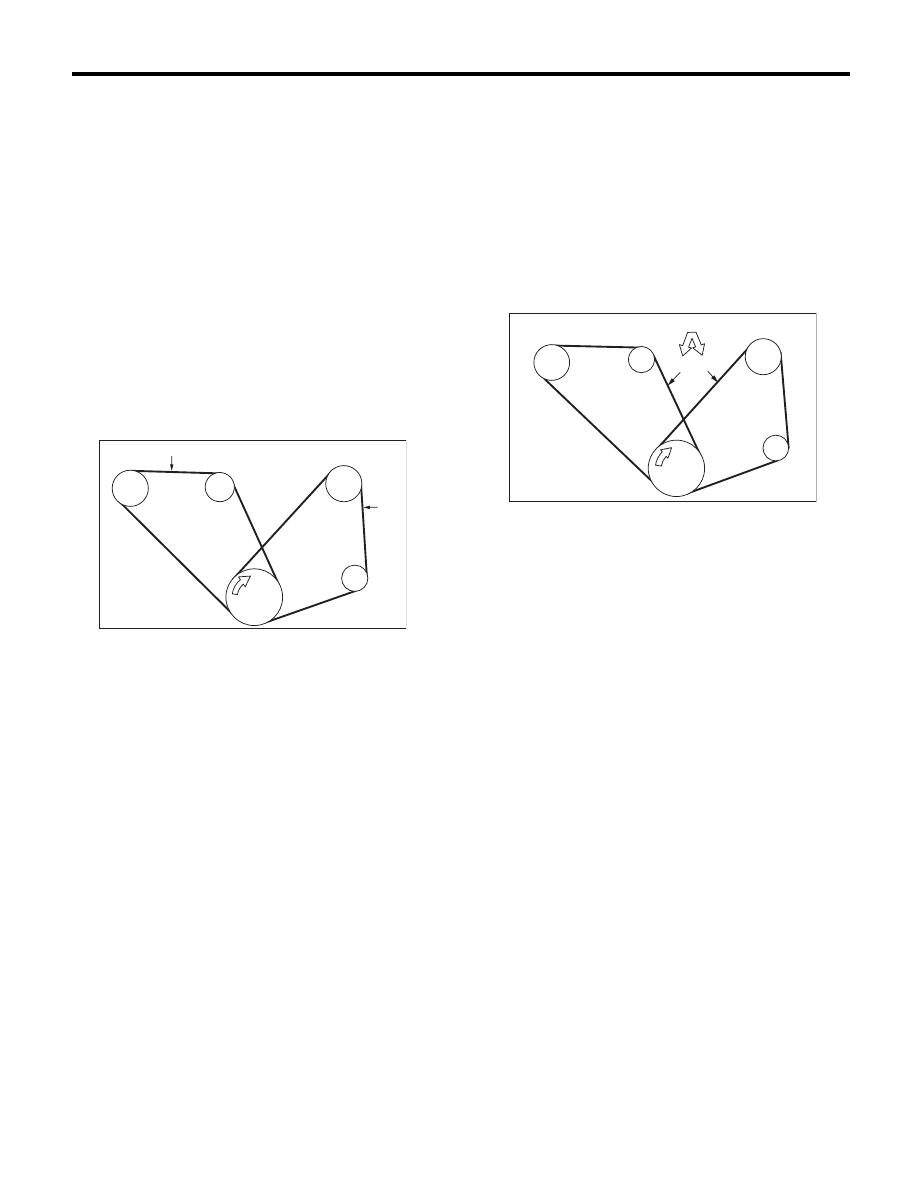

V-belt

MECHANICAL

C: INSPECTION

1) Replace the belts, if crack, fraying or wear is

found.

2) Check the belt tension and adjust it if necessary

by changing the generator installing position or

idler pulley installing position.

Belt tension (with belt tension gauge):

(A)

When installing new parts:

640 — 780 N (65 — 80 kgf, 144 — 175 lb)

At inspection:

490 — 640 N (50 — 65 kgf, 110 — 144 lb)

(B)

When installing new parts:

650 — 750 N (66 — 76 kgf, 146 — 169 lb)

At inspection:

350 — 450 N (36 — 46 kgf, 78 — 101 lb)

Belt tension (without belt tension gauge):

(A)

When installing new parts:

7 — 9 mm (0.276 — 0.354 in)

At inspection:

9 — 11 mm (0.354 — 0.433 in)

(B)

When installing new parts:

7.5 — 8.5 mm (0.295 — 0.335 in)

At inspection:

9.0 — 10.0 mm (0.354 — 0.394 in)

(A) Front side belt

(B) Rear side belt

C/P Crank pulley

GEN Generator pulley

P/S Power steering oil pump pulley

A/C A/C compressor pulley

I/P Idler pulley

C/P

P/S

A/C

GEN

(A)

(B)

I/P

PM-00154

(A) Front side belt

(B) Rear side belt

(C) 98 N (10 kg, 22 lbf)

C/P Crank pulley

GEN Generator pulley

P/S Power steering oil pump pulley

A/C A/C compressor pulley

I/P Idler pulley

ME-00226

(A) (B)

(C)

GEN

C/P

I/P

A/C

P/S