Subaru Legacy IV (2008 year). Manual - part 59

ME(H4SO)-32

Engine Assembly

MECHANICAL

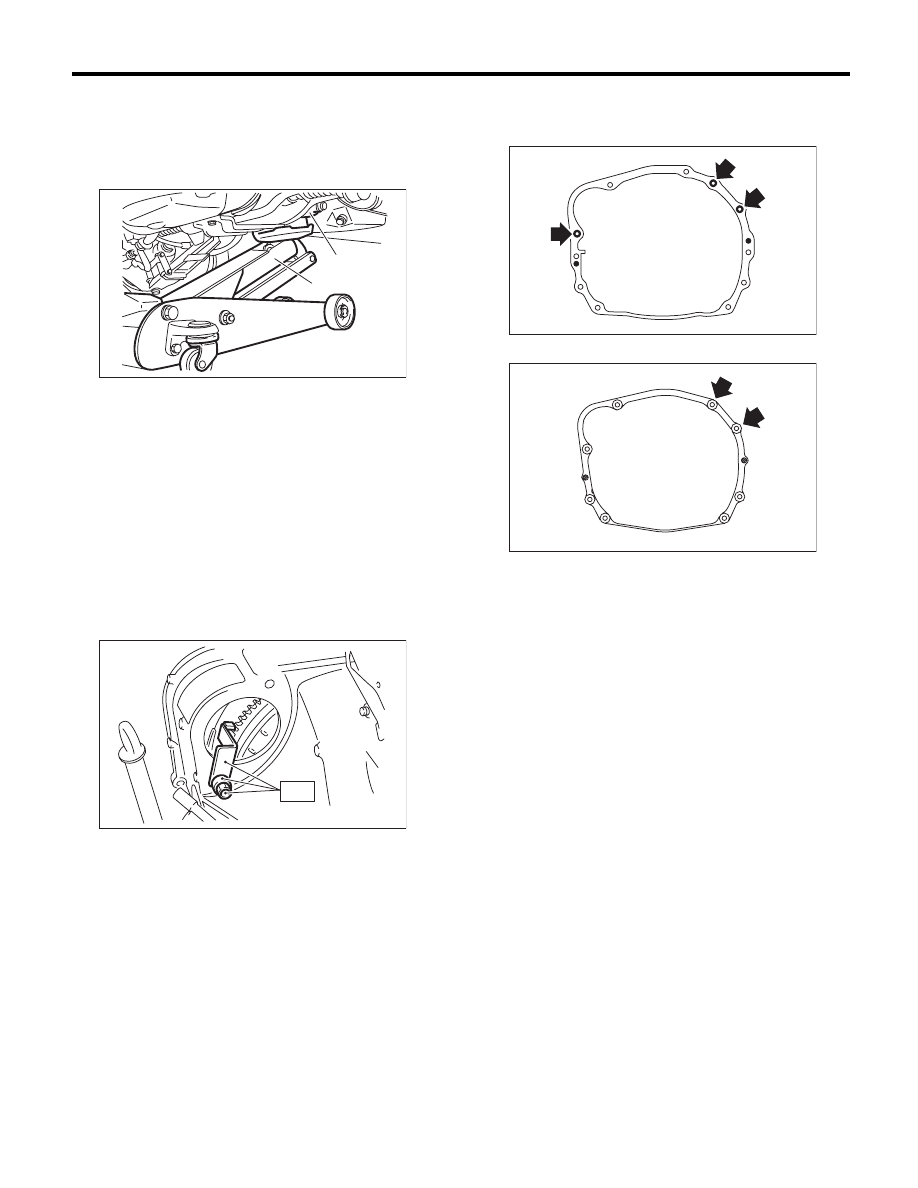

24) Support the transmission with a garage jack.

CAUTION:

Be sure to always perform this work, in order to

prevent the transmission from lowering for its

own weight.

25) Separation of engine and transmission

CAUTION:

Before removing the engine away from trans-

mission, check to be sure no work has been

overlooked.

(1) Remove the starter. <Ref. to SC(H4SO)-6,

REMOVAL, Starter.>

(2) Attach the ST to the torque converter clutch

case. (AT model)

ST

498277200

STOPPER SET

(3) Remove the bolts which hold upper side of

transmission to engine.

• AT model

• MT model

26) Remove the engine from vehicle.

(1) Slightly raise the engine.

(2) Raise the transmission with garage jack.

(3) Move the engine horizontally until main

shaft is withdrawn from clutch cover. (MT mod-

el)

(4) Slowly move the engine away from engine

compartment.

NOTE:

Be careful not to damage adjacent parts or body

panels with crank pulley, oil level gauge, etc.

27) Remove the engine mounting from the engine.

(A) Transmission

(B) Garage jack

ME-00215

(B)

(A)

ST

ME-00217

AT-00106

MT-01524