SsangYong Rexton. Manual - part 399

SSANGYONG Y200

1F1-4 M162 ENGINE CONTROLS

CLEARING FAILURE CODES

Notice:To prevent Engine Control Module(ECM) damage, the key must be OFF when disconnecting or reconnecting

the power to the ECM (for example battery cable, ECM pigtail connector, ECM fuse, jumper cables, etc.)

Parameters listed in the table may not be exactly the same as your reading due to the type of instrument or other

factors. If a failure code is displayed during the “TROUBLE CODE” in scan tool check mode, check the circuit for

the code listed in the table below. For details of each code, turn to the page referred to under the “See Page” for

the re-spective “Failure Code” in the below table.

Failure codes should be cleared after repairs have been completed.

DIAGNOSTIC INFORMATION AND PROCEDURE

FAILURE CODE DIAGNOSIS

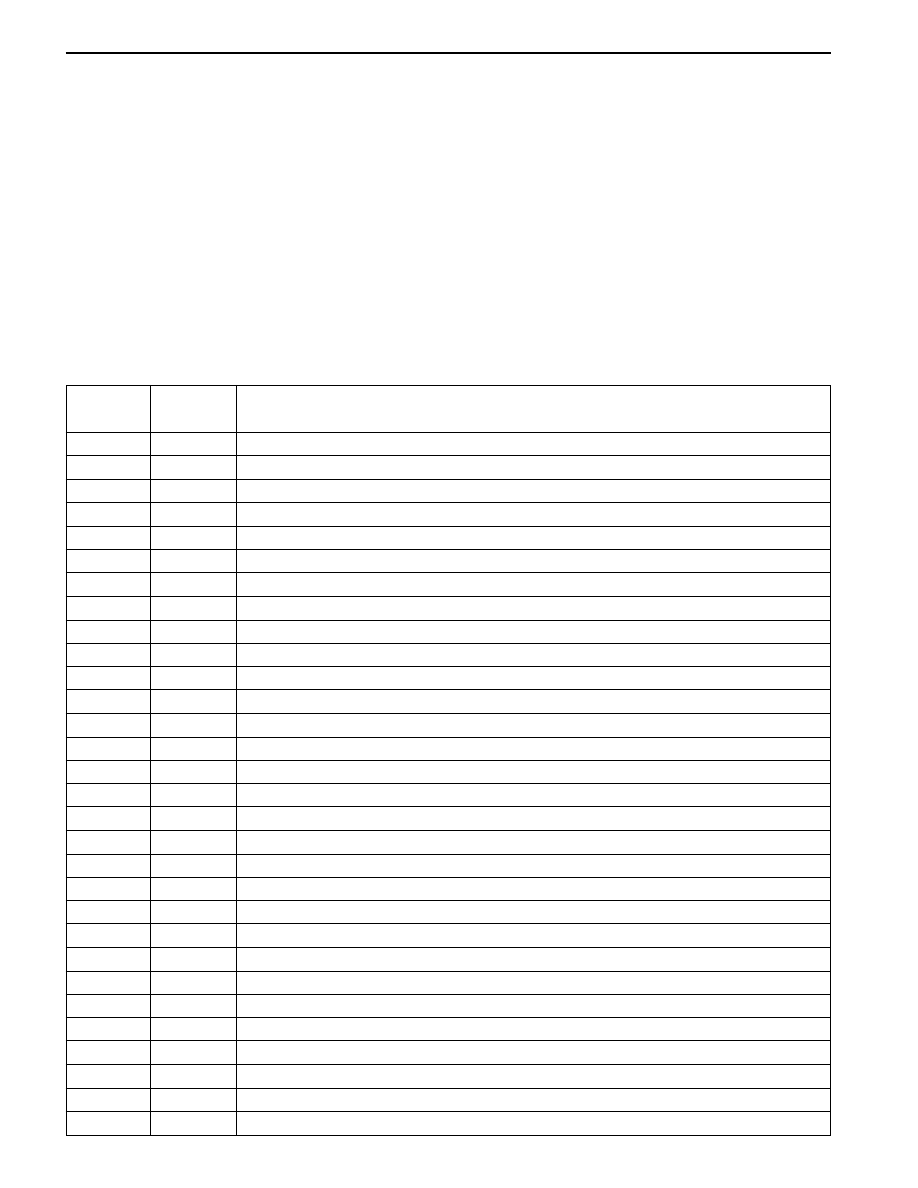

FAILURE CODES TABLE

Failure

Code

00

01

02

03

04

05

06

08

09

10

11

17

18

19

20

21

23

24

25

26

27

29

30

31

32

33

34

35

40

41

Description

Engine coolant temperature sensor low voltage

Engine coolant temperature sensor high voltage

Engine coolant temperature sensor plausibility

Intake air temperature sensor low voltage

Intake air temperature sensor high voltage

Intake air temperature sensor plausibility

Engine coolant temperature insufficient for closed loop fuel control

System voltage too low

Mass air flow sensor plausibility

Mass air flow sensor low voltage

Mass air flow sensor high voltage

Crankshaft position sensor signal failure (no engine revolution signal)

Crankshaft position sensor signal failure (rpm > max. value)

Camshaft position senosr signal : No.1 cylinder recognition failure

Crankshaft position sensor signal failure (gap recognition failure)

Transmission coding failure

CAN communication failure : ASR/MSR

CAN communication failure : ABS

Communication with transponder missing

CAN communication failure : TCU (A/T only)

CAN communication failure : TOD (E32 only)

CAN communication failure : ID 200h not plausible

CAN communication failure : ID 208h not plausible

CAN communication failure : communication initialization failure

Engine rpm output circuit short circuit to battery

Engine rpm output circuit short circuit to ground or open

Fuel pump relay short circuit to battery

Fuel pump relay short circuit to ground or open

Purge control valve short circuit to battery

Purge control valve short circuit to ground or open

See Page

1F1-56

1F1-56

1F1-56

1F1-52

1F1-52

1F1-52

1F1-56

1F1-28

1F1-52

1F1-52

1F1-52

1F1-13

1F1-13

1F1-17

1F1-13

1F1-79

1F1-77

1F1-77

1F1-82

1F1-77

1F1-78

1F1-78

1F1-78

1F1-78

1F1-68

1F1-68

1F1-33

1F1-33

1F1-41

1F1-41