SsangYong Rexton. Manual - part 311

M162 ENGINE MECHANICAL 1B1-47

SSANGYONG Y200

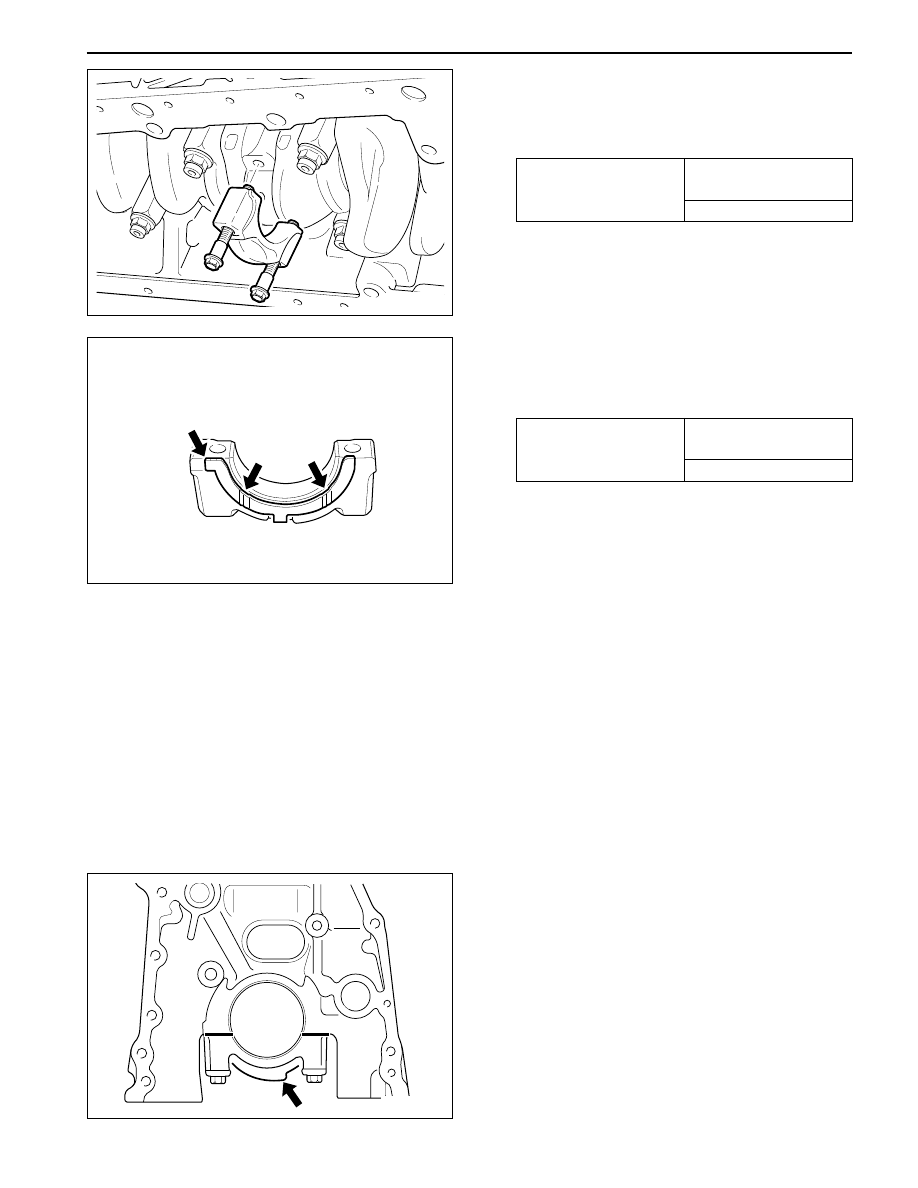

Notice:

•

Make sure the crankshaft bearing cap properly

seated in place in the crankcase side. When

perfectly installed, the projected part (arrow)

locates in the left side (intake manifold side).

•

Assemble so that the projected part of the cap

and crankcase face the same direction.

Removal & Installation Procedure

1. Unscrew the connecting rod bearing cap bolt and

remove the bearing cap.

Installation Notice

2. Unscrew the crankshaft bearing cap bolts and

separate the upper and lower bearing shells and

thrust washers.

Installation Notice

•

Remove the bearing cap from front (pulley side)

to rear.

•

Make sure that the upper and lower bearing

shells do not change each other and coat with

engine oil.

•

The oil grooves (arrows) in the thrust washers

must face outward and insert the thrust bearing

into the bearing cap.

•

There are five kinds of thrust washers by

thickness. Select the proper washer when

repaired.

3. Remove the crankshaft.

4. Installation should follow the removal procedure

in the reverse order.

5. After completion of the installation, check for the

rotating condition of the crankshaft.

•

Make sure that the upper and lower bearing

shells do not change each other.

•

Coat the bearing shell with engine oil.

•

Install the bearing cap according to the

consecutive number.

YAD1B900

YAD1B910

YAD1B920

Tightening Torque

1st step: 40 + 5 N•m

(30 + 3.7 lb-ft)

2nd step: 90° + 10°

Part No. : 601 030 00 62

2.15 mm

Part No. : 601 030 01 62

2.20 mm

Part No. : 601 030 02 62

2.25 mm

Part No. : 601 030 03 62

2.30 mm

Part No. : 601 030 04 62

2.40 mm

Tightening Torque

1st step: 50 - 60 N•m

(37 - 44 lb-ft)

2nd step: 90°