SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 12

1B-27

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE MECHANICAL

M162 GSL ENG SM - 2005.7

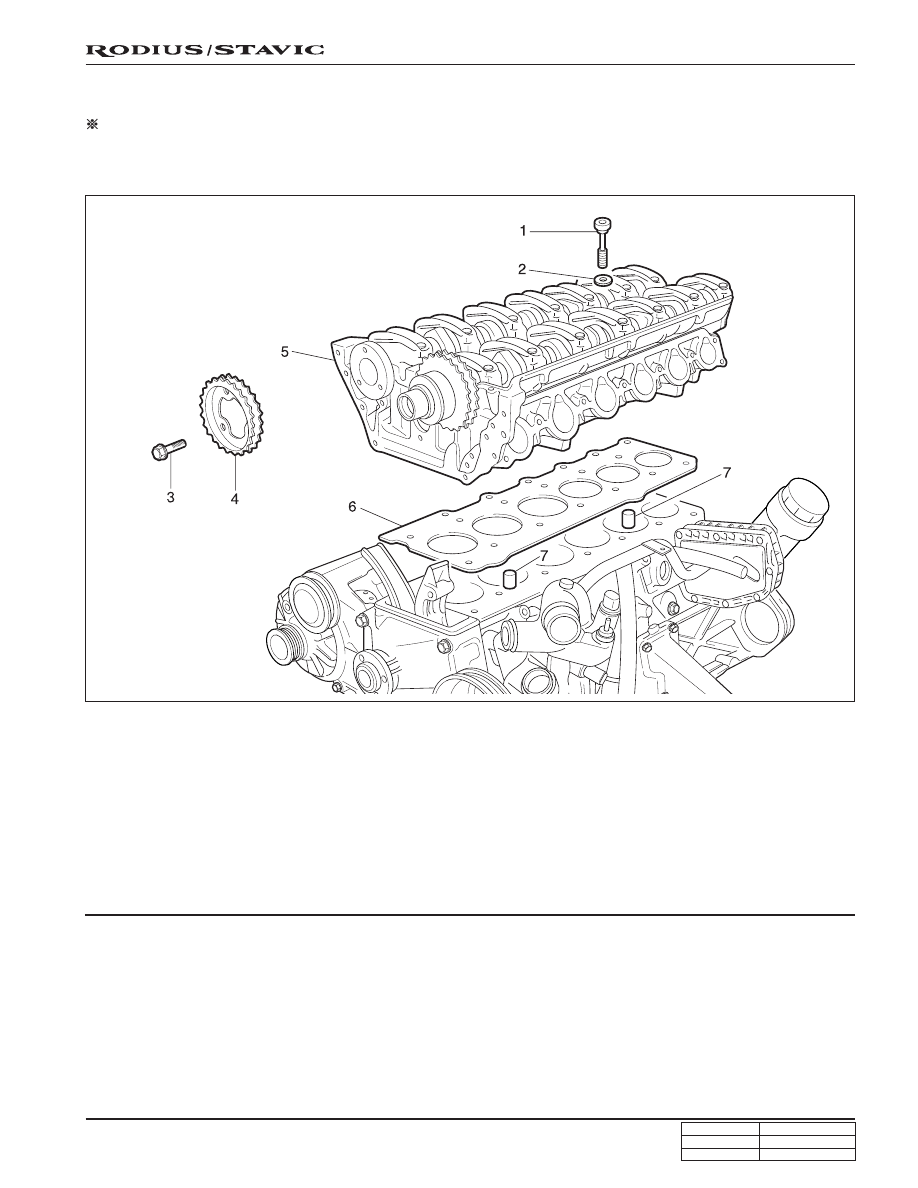

CYLINDER HEAD

Preceding Work: Removal of cylinder head cover

Removal of cylinder head front cover

Removal of upper intake manifold

1. Cylinder head bolt (14 pieces)

......................... 1st step: 55 Nm (141 lb-ft)

2nd step: 90°

3rd step: 90°

2. Washers (14 pieces)

3. Flange bolts (3 pieces)

......................... 1st step: 18 ~ 22 Nm (13 ~ 16 lb-ft)

2nd step: 90° ± 5°

4. Exhaust camshaft sprocket

5. Cylinder head

6. Gasket .......................................................... Replace

7. Dowel sleeve