SsangYong Korando III (2010 year). Manual - part 225

03-13

3190-01

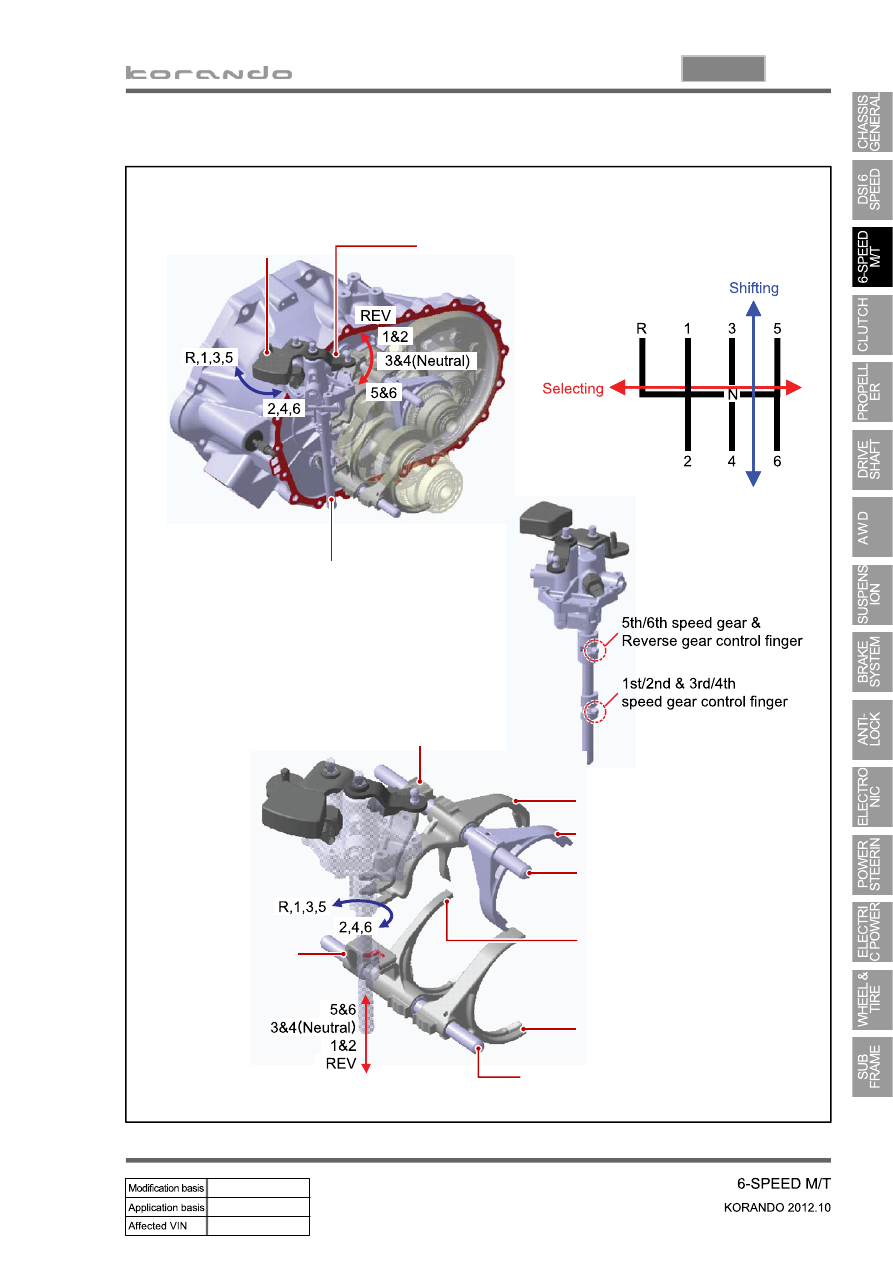

3. SHIFTING MECHANISM

Control shaft

Shift lever

Selector lever

5th/6th speed gear shift lug

Reverse gear shift fork

5th/6th speed gear shift fork

5th/6th speed gear & Reverse

shift rail

1st/2nd speed gear shift fork

3rd/4th speed gear shift fork

1st/2nd, 3rd/4th speed gear shift rail

3rd/4th speed

gear shift lug