SsangYong Korando II (1996-2006 year). Manual - part 448

SSANGYONG MY2002

9L-8 GLASS AND MIRRORS

KAA9L140

Notice: The grid line repair material must be cured

with heat. In order to avoid heat damage to the

interior trim, protect the trim near the repair area

where heat will be applied.

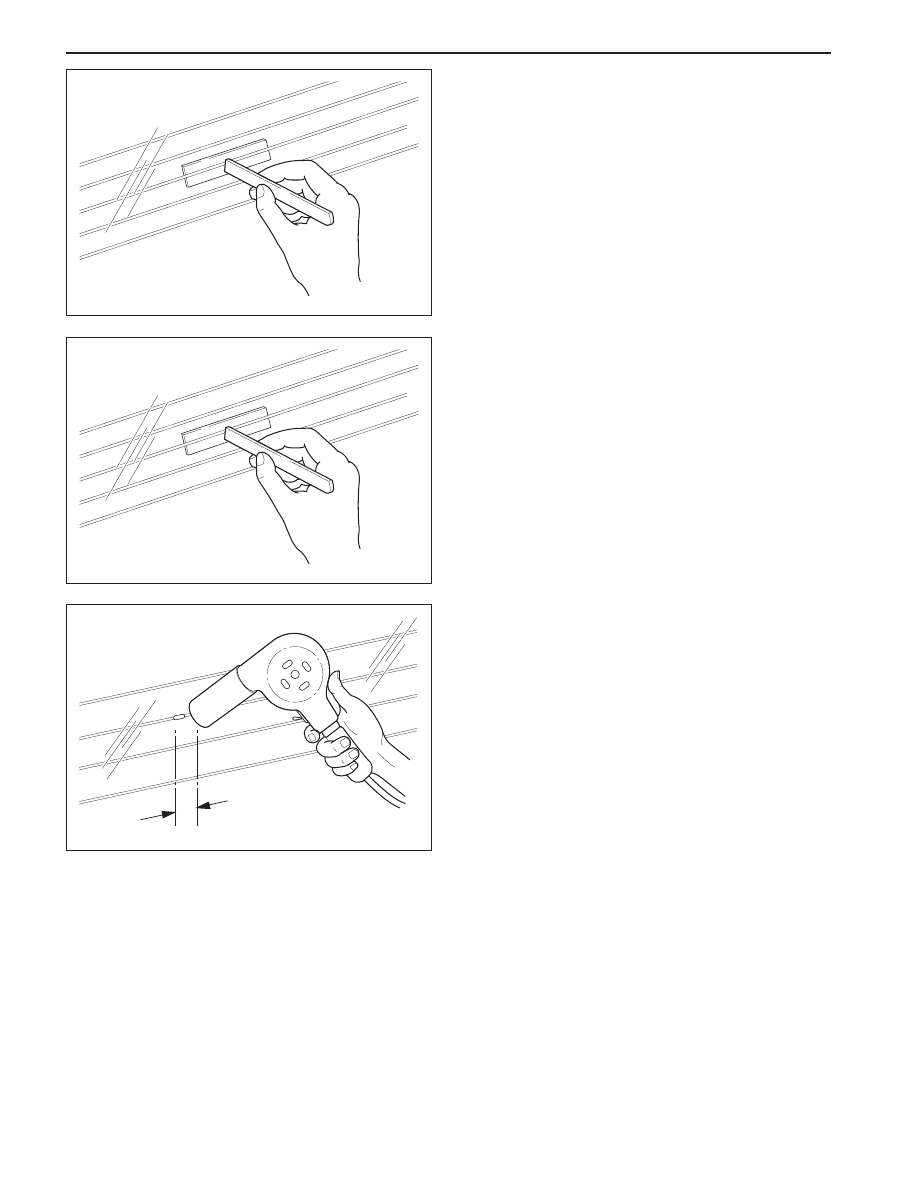

9. Heat the repair area for 1 to 2 minutes.

10. Hold the heat gun nozzle 25 mm (1 inch) from the

surface. A minimum temperature of 149°C (300°F)

is required.

11. Inspect the grid line repair area. If the repair

appears discolored, apply a coating of tincture of

iodine to the area using a pipe cleaner or a line

brush. Allow the iodine to dry for about 30

seconds. Carefully wipe off the excess iodine with

a lint-free cloth.

12. Test the operation of the rear window defogger in

order to verify that the repair was successful.

Important: At least 24 hours is required for

complete curing of the repair materials. The repair

area should not be physically disturbed until after

that time.

13. Installation should follow the removal procedure

in the reverse order.

KAA9L130

REAR WINDOW DEFOGGER GRID

LINE REPAIR

1. Disconnect the negative battery cable.

2. Disconnect the rear window defogger electrical

connector.

3. Inspect the rear window defogger grid lines.

4. Mark the grid line break on the outside of the glass

with a wax pencil or a crayon.

5. Buff the grid lines that are to be repaired with steel

wool. Wipe the lines clean using a cloth dampened

with alcohol. Buff and clean about 6 mm (0.25 inch)

beyond each side of the break in the grid line.

KAA9L130

6. Attach a grid line repair decal or two strips of tape

above and below the repair areas.

•

A repair decal or tape must be used in order to

control the width of the repair areas.

•

If a decal is used, the die-cut metered slot must

be the same width as the grid line.

7. Apply the grid repair material to the repair area

using a small wooden stick or a spatula. The grid

repair material should be at room temperature.

8. Carefully remove the decal or the tape.