SsangYong Korando II (1996-2006 year). Manual - part 410

SSANGYONG MY2002

8B-56 SUPPLEMENTAL RESTRAINTS SYSTEM

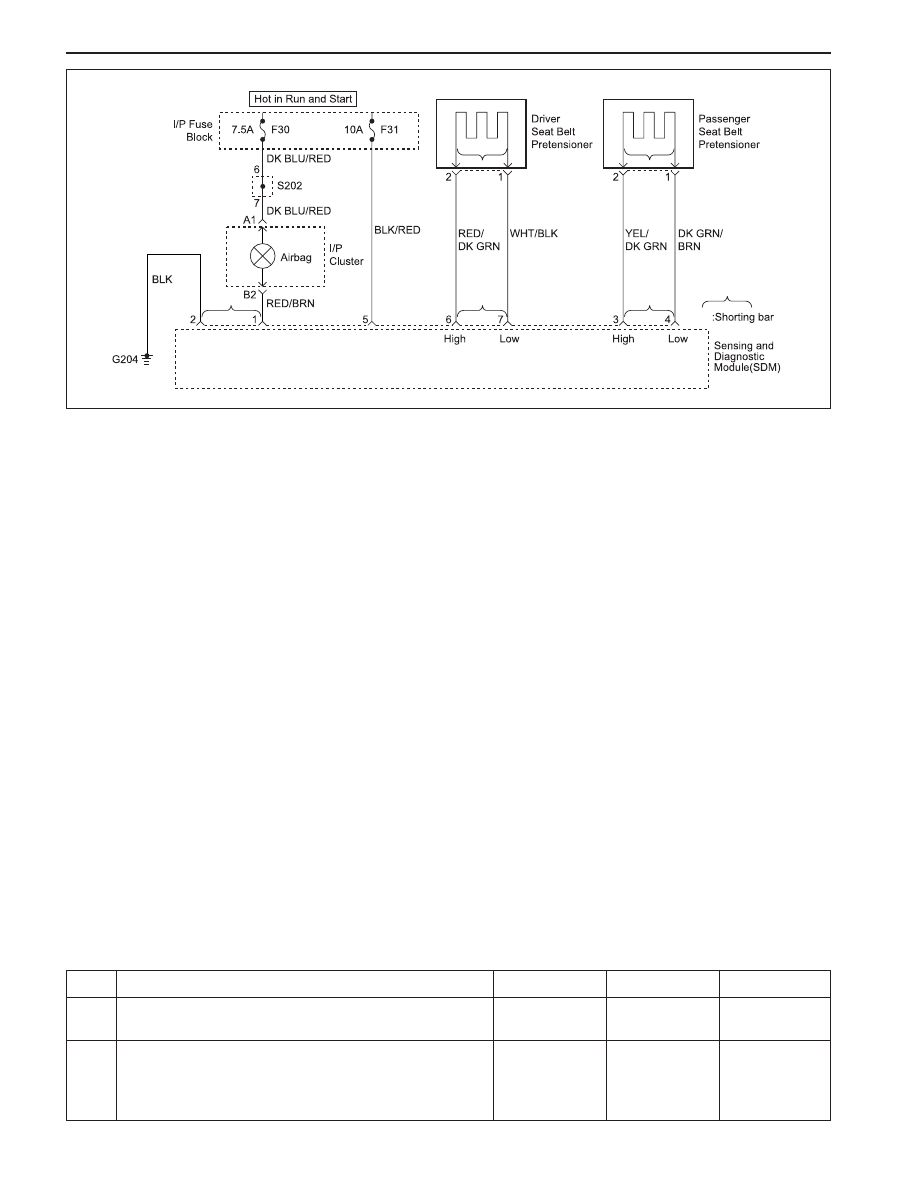

Circuit Description

When the ignition switch is first turned ON, ignition voltage

applied to the indicator lamp and also to the sensing

and diagnostic module (SDM) input terminal 5. The SDM

respond by illuminating the airbag indicator in instrument

cluster for 4.5 seconds. If the SDM cannot detect ignition

voltage at terminal 5, a DTC 47 will be set.

DTC 47 Will Set When

DTC 47 will set when during the continuos monitoring,

the SDM fails to detect normal operating voltage at

terminal 5, the input terminal for ignition voltage supply.

DIAGNOSTIC TROUBLE CODE (DTC) 47

BATTERY VOLTAGE IS OUT OF SPECIFICATION

Action Taken

The SDM will illuminates the airbag indicator, but the

indicator will not turn on if the inputs have not been

correctly processed.

DTC 47 Will Clear When

The ignition switch is turned OFF or the problem is

repaired.

KAA8B120

DTC 47 - Battery Voltage is Out of Specification

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

s e r v i c e u n t i l o n e m i n u t e h a s p a s s e d a f t e r

disconnecting power to the SDM. Otherwise, injury

could result.

Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS.

The SDM could be activated if it is powered when it

is not rigidly attached to the vehicle, resulting in

unexpected deployment and possible injury.

Perform the SRS Diagnostic System Check.

Is the SRS Diagnostic System Check complete?

1. Repair or replace the faulty wires, terminals or

connectors.

2. Connect all the SRS components.

Is the repair complete?

Step

Action

Value(s)

Yes

No

1

-

Go to Step 3

Go to Step 4

3

-

Go to Step 2

-