SsangYong Korando II (1996-2006 year). Manual - part 275

5A-4 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

•

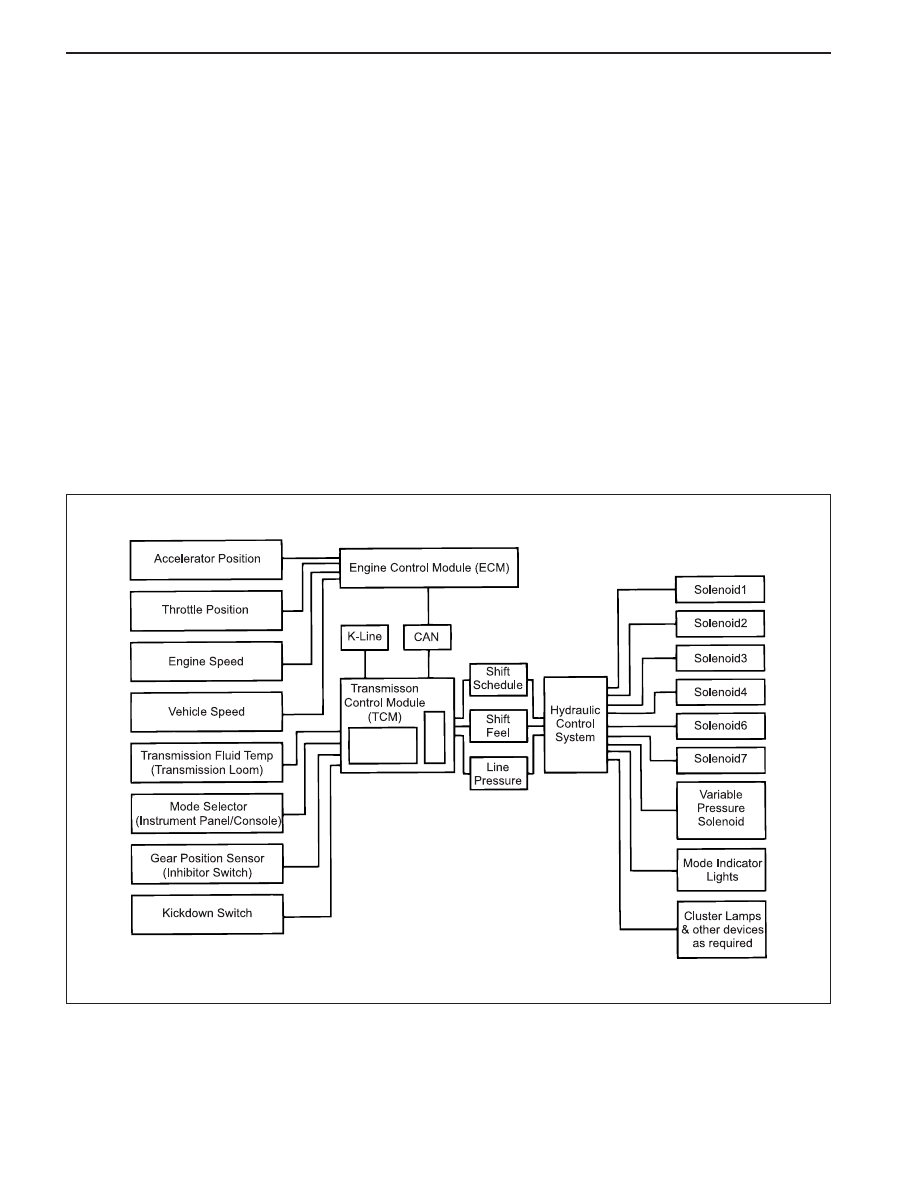

Output circuits which control external devices such

as the Variable Pressure Solenoid (VPS) driver, On/

Off solenoid drivers, a diagnostics output and the

driving mode indicator light.

Processing Logic

Shift schedule and calibration information is stored in

an Erasable Programmable Read Only Memory (EPROM).

Throttle input calibration constants and the diagnostics

information are stored in Electrically Erasable Program-

mable Read Only Memory (EEPROM) that retains the

memory even when power to the TCM is disconnected.

TCM continuously monitors the input values and uses

these, via the shift schedule, to determine the required

gear state. At the same time it monitors, via the solenoid

outputs, the current gear state, whenever the input

conditions change such that the required gear state is

different to the current gear state, the TCM initiates a

gear shift to bring the two states back into line.

Once the TCM has determined the type of gearshift

required the TCM accesses the shift logic, estimates

the engine torque output, adjusts the variable pressure

solenoid ramp pressure then executes the shift.

The TCM continuously monitors every input and output

circuit for short or open circuits and operating range.

When a failure or abnormal operation is detected the

TCM records the condition code in the diagnostics

memory and implements a Limp Home Mode (LHM).

The actual limp home mode used depends upon the

failure detected with the object to maintain maximum

drive-ability without damaging the transmission. In

general input failures are handled by providing a default

value. Output failures, which are capable of damaging

the transmission, result in full limp mode giving only

third or fourth gear and reverse. For further details of

limp modes and memory retention refer to the

Diagnostic Trouble Code Diagnosis Section.

T h e T C M i s d e s i g n e d t o o p e r a t e a t a m b i e n t

temperatures between - 40 and 85 °C (- 40 and 185 °F).

It is also protected against electrical noise and voltage

spikes, however all the usual precautions should be

observed, for example when arc welding or jump

starting.

TCM Inputs

To function correctly, the TCM requires engine speed,

vehicle speed, transmission fluid temperature, throttle

position, gear position and Kickdown Switch inputs to

determine the variable pressure solenoid current ramp

and on/off solenoid states.

KAA5A030

This ensures the correct gear selection and shift feel

for all driving conditions.

The inputs required by the TCM are as follows;