содержание .. 46 47 48 49 ..

Peugeot 405. Manual - part 48

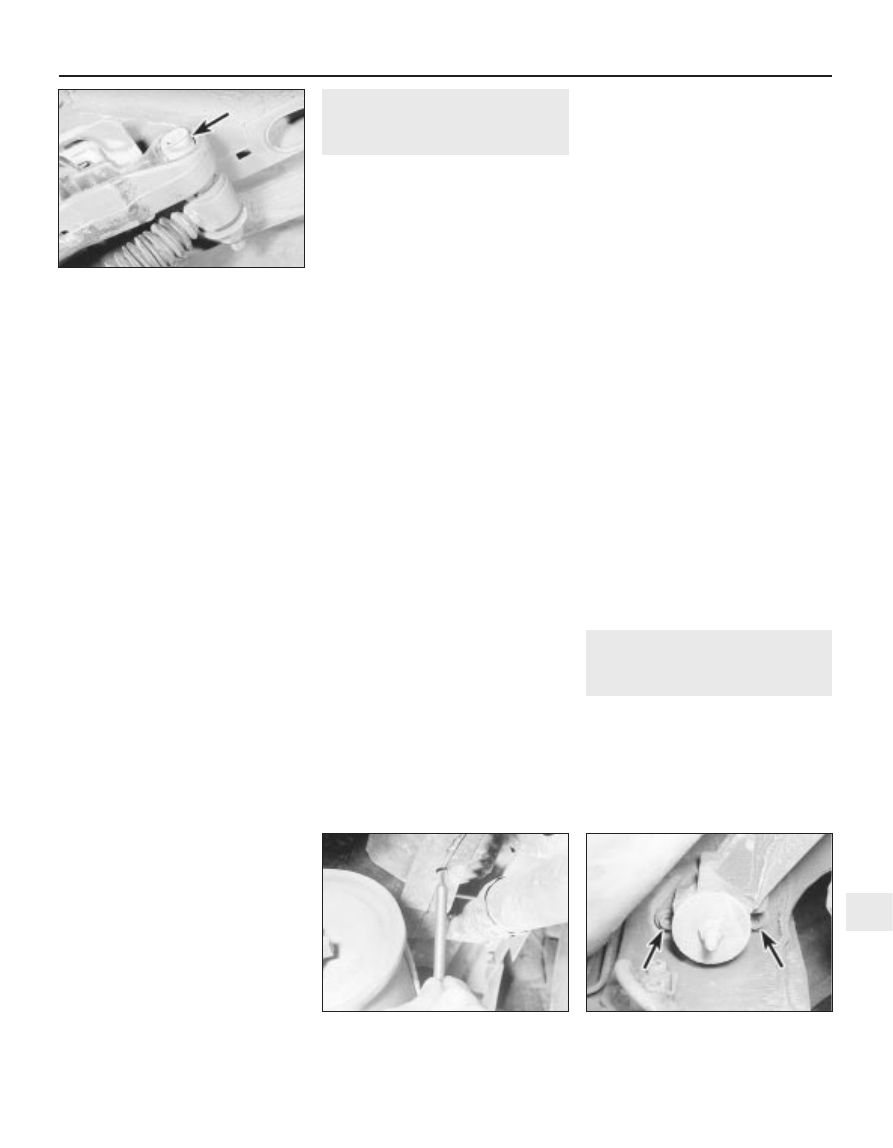

shock absorber upper and lower securing

nuts. Recover the washers (see illustration).

4 Tap the bolts from the mountings to free the

shock absorber, then withdraw the unit from

under the vehicle.

Testing

5 Examine the shock absorber for signs of

fluid leakage or damage. Test the operation of

the shock absorber, while holding it in an

upright position, by moving the piston through

a full stroke and then through short strokes of

50 to 100 mm. In both cases, the resistance

felt should be smooth and continuous. If the

resistance is jerky, or uneven, or if there is any

visible sign of wear or damage, renewal is

necessary.

6 Also check the rubber mounting bushes for

damage and deterioration. New bushes can

be fitted using a long bolt, nut and spacers to

draw the bush into position. Lubricate the new

bush with soapy water to aid fitting.

7 Inspect the shanks of the mounting bolts

for signs of wear or damage, and renew as

necessary.

Refitting

8 Prior to refitting the shock absorber, mount

it upright in the vice, and operate it fully

through several strokes in order to prime it.

Apply a smear of multi-purpose grease to

both the shock absorber mounting bolts.

9 Manoeuvre the shock absorber into

position, and insert its mounting bolts (with

washers in place). Note that the bolts fit from

the inside of the vehicle, ie the nuts fit on the

roadwheel side of the shock absorber.

10 Fit the washers and new nuts to the

mounting bolts, but do not tighten the fixings

at this stage.

11 Measure the distance between the shock

absorber bolt centres, and load the vehicle (by

adding weight to the luggage compartment)

until a distance of 328.0 mm is obtained

between the bolt centres. Tighten the shock

absorber mounting nuts and bolts to the

specified torque.

12 Drive the vehicle off the ramps.

14 Rear axle assembly -

removal and refitting

4

Removal

Note: Before carrying out this procedure, it is

advisable to run the fuel tank as near empty as

possible to minimise the amount of fuel which

has to be drained from the tank.

1 Chock the front wheels, then jack up the

rear of the vehicle and support securely on

axle stands, until the trailing arms are at

maximum extension, with the roadwheels still

resting on the ground (see “Jacking and

Vehicle Support”).

2 Where applicable, remove the rear

underbody shield.

3 Remove the rear and intermediate exhaust

sections as described in Chapter 4.

4 Empty the fuel tank by either disconnecting

the filler pipe and draining, or by siphoning the

fuel out through the filler neck. In either case,

collect the fuel in a container which can be

sealed.

5 Disconnect the fuel filler pipe from the tank

(If not already done). Plug the open ends of

the tank and the hose to prevent dirt ingress.

6 Remove the rear exhaust heat shield from

the underbody.

7 Disconnect the handbrake cables from the

adjuster mechanism under the rear

underbody, with reference to Chapter 9.

8 Release the handbrake cables from any

clips and brackets, and move them clear of

the suspension components to facilitate

removal.

9 Loosen the fuel tank support strap bolts as

far as possible without removing them, and

lower the fuel tank.

10 Disconnect the brake fluid pipes at the

unions on the rear suspension assembly, with

reference to Chapter 9. Plug the open ends of

the unions.

11 On models with a load-sensitive rear

brake pressure regulating valve, disconnect

the hydraulic pipes at the valve. Again, plug

the opens ends of the pipes and the valve.

12 Where applicable, remove the rear ABS

wheel sensors. Note that there is no need to

disconnect the wiring connectors, but unclip

the wiring harnesses from the rear suspension

components, and move the sensors to one

side, clear of the working area.

13 Place a trolley jack under the rear

suspension tubular crossmember to support

the suspension assembly.

14 Make a final check to ensure that all

relevant pipes and wires have been

disconnected to facilitate removal of the

suspension assembly.

15 Using a long-reach splined adapter,

unscrew the suspension assembly rear

securing bolts, accessible through the holes

in the suspension assembly side members

(see illustration).

16 Working at the front of the suspension

assembly, unscrew the two bolts on each side

securing the front mountings to the

underbody

(see illustration).

17 Lower the trolley jack slightly, and pull the

suspension rearwards. If necessary, raise the

vehicle body in order for the suspension to

clear the fuel tank, then withdraw the

suspension assembly from under the vehicle.

Refitting

18 Refitting is a reversal of the removal

procedure, bearing in mind the following

points.

a) Tighten all fixings to the specified torque.

b) Bleed the brake hydraulic system as

described in Chapter 9.

c) Adjust the handbrake mechanism as

described in Chapter 9.

d) On completion, have the rear ride height

checked by a Peugeot dealer.

15 Vehicle ride height - checking

5

Checking of the vehicle ride height requires

the use of Peugeot special tools to accurately

compress the suspension in a suspension

checking bay.

The operation should be entrusted to a

Peugeot dealer, as it not possible to carry out

checking accurately without the use of the

appropriate tools.

Suspension and steering 10•11

14.16 Unscrew the two bolts (arrowed) on

each side securing the suspension

mountings to the body

14.15 Using a long-reach splined adapter

to unscrew a suspension assembly

rear securing bolt

13.3 Rear shock absorber

upper mounting bolt (arrowed)

10