содержание .. 10 11 12 13 ..

Peugeot 405. Manual - part 12

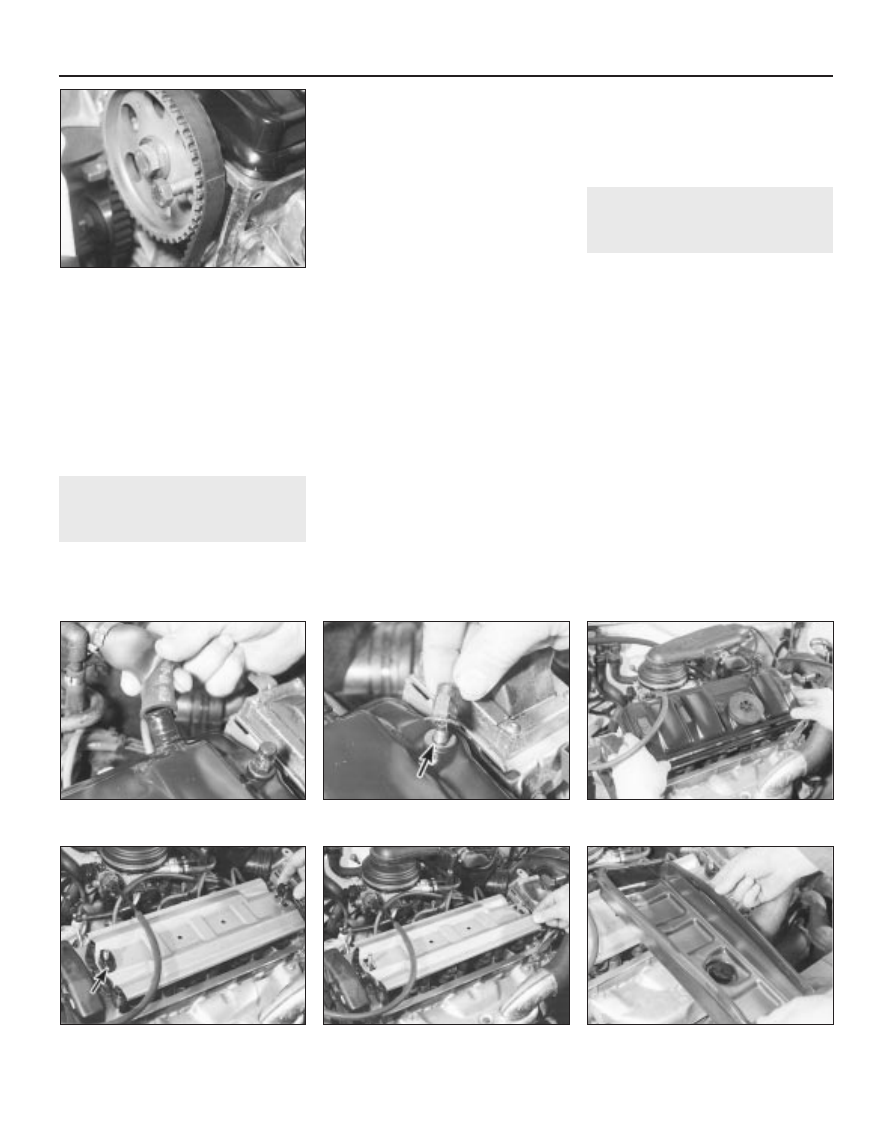

rotate the crankshaft slightly, to get the holes

to align.

5 With the flywheel correctly positioned,

insert a 10 mm diameter bolt or a drill through

the timing hole in the camshaft sprocket, and

locate it in the hole in the cylinder head (see

illustration).

6 The crankshaft and camshaft are now

locked in position, preventing unnecessary

rotation.

4

Cylinder head cover -

removal and refitting

2

Removal

1 Disconnect the battery negative lead.

2 Where necessary, undo the bolts securing

the HT lead retaining clips to the rear of the

cylinder head cover, and position the clips

clear of the cover.

3 Slacken the retaining clip, and disconnect

the breather hose from the left-hand end of

the cylinder head cover (see illustration).

Where the original crimped-type Peugeot

hose clip is still fitted, cut it off and discard it.

Use a standard worm-drive clip on refitting.

4 Undo the two retaining nuts, and remove

the washer from each of the cylinder head

cover studs (see illustration).

5 Lift off the cylinder head cover, and remove

it along with its rubber seal (see illustration).

Examine the seal for signs of damage and

deterioration, and if necessary, renew it.

6 Lift off the spacer from each stud, and

remove the oil baffle plate (see illustrations).

Refitting

7 Carefully clean the cylinder head and cover

mating surfaces, and remove all traces of oil.

8 Fit the rubber seal over the edge of the

cylinder head cover, ensuring that it is

correctly located along its entire length (see

illustration).

9 Refit the oil baffle plate to the engine, and

locate the spacers in their recesses in the

baffle plate.

10 Carefully refit the cylinder head cover to

the engine, taking great care not to displace

the rubber seal.

11 Check that the seal is correctly located,

then refit the washers and cover retaining

nuts, and tighten them to the specified torque.

12 Where necessary, refit the HT lead clips to

the rear of the head cover, and securely

tighten their retaining bolts.

13 Reconnect the breather hose to the

cylinder head cover, securely tightening its

retaining clip, and reconnect the battery

negative lead.

5

Timing belt covers - removal

and refitting

2

Removal

Upper cover

1 Slacken and remove the two retaining bolts

(one at the front and one at the rear), and

remove the upper timing cover from the

cylinder head (see illustrations).

Centre cover

2 Remove the upper cover as described in

paragraph 1, then free the wiring from its clips

on the centre cover (see illustration).

3 Slacken and remove the three retaining

bolts (one at the rear of the cover, beneath the

engine mounting plate, and two directly above

the crankshaft pulley), and manoeuvre the

centre cover out from the engine

compartment

(see illustration).

Lower cover

4 Remove the auxiliary drivebelt as described

in Chapter 1.

5 Remove the upper and centre covers as

described in paragraphs 1 to 3.

4.8 On refitting, ensure the rubber seal is

located on the cylinder head cover

2A•4 TU engine in-car repair procedures

3.5 . . . then insert a 10 mm bolt through

the cam sprocket timing hole, and locate it

in the cylinder head

4.4 . . . then slacken and remove the cover

retaining nuts and washers (arrowed) . . .

4.6b . . . and remove the oil baffle plate

4.6a Lift off the spacers

(second one arrowed) . . .

4.5 . . . and lift off the cylinder head cover

4.3 Disconnect the breather hose from the

cylinder head cover . . .