Content .. 2391 2392 2393 2394 ..

Opel Frontera UBS. Manual - part 2393

6A – 46 ENGINE MECHANICAL

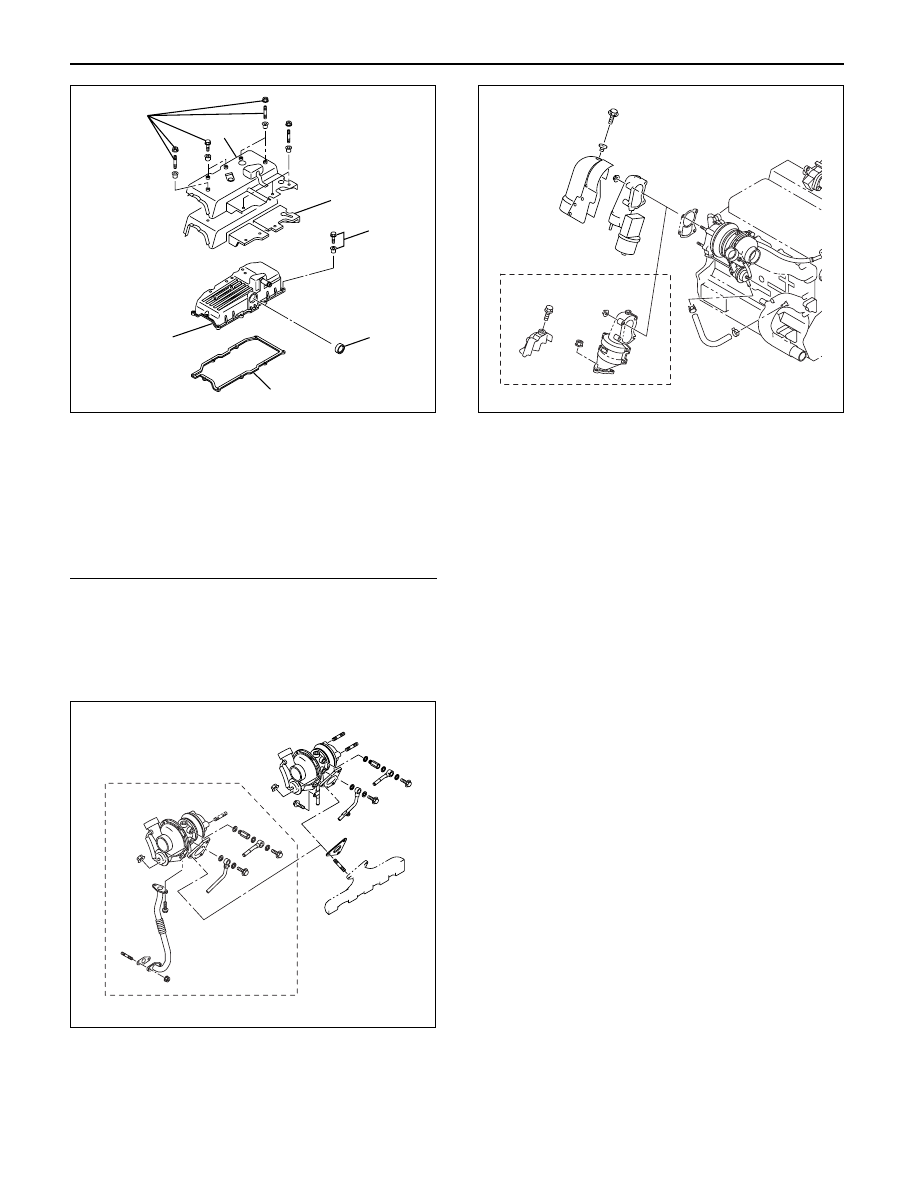

Legend

(1) Cylinder Head Noise Insulator Cover

(2) Insulator

(3) Bolt

(4) Oil Seal

(5) Gasket

(6) Cylinder Head Cover

(7) Bolt, Stud and Rubber Mounting

21. Install water hose between thermostat and radiator.

22. Install turbocharger assembly to exhaust manifold.

Torque: 27 N·m (2.8 kg·m/20 lb ft)

23. Install water hose and oil pipe for turbocharger.

24. Install exhaust valve assembly and heat protector.

Torque: 57 N·m (5.8 kg·m/42 lb ft) for valve

Torque: 9 N·m (0.9 kg·m/78 lb in) for heat protector

25. Install generator assembly.

Torque: 40 N·m (4.1 kg·m/30 lb ft) for ACG bracket

Torque: 40 N·m (4.1 kg·m/30 lb ft) between ACG and

bracket

Torque: 20 N·m (2.0 kg·m/14 lb ft) between ACG

and adjuster plate

26. Fix the A/C compressor bracket and install A/C

compressor.

Torque: 46 N·m (4.7 kg·m/34 lb ft) for A/C bracket

Torque: 20 N·m (2.0 kg·m/14 lb ft) for belt tensioner

27. Reconnect harness connector around cylinder

head.

28. Connect EGR vacuum hose.

29. Install oil level gauge guide assembly.

Tighten nuts lower portion and tighten bolt.

Torque: 20 N·m (2.0 kg·m/14 lb ft)

30. Install intercooler assembly.

Refer to “Intercooler” in this manual.

31. Install air duct between air cleaner and

turbocharger.

32. Fill engine coolant.

33. Reconnect battery.

For Europe

025R200007

For Europe

025R200006

1

7

2

3

4

5

6

010R200006