Content .. 2382 2383 2384 2385 ..

Opel Frontera UBS. Manual - part 2384

6A – 10 ENGINE MECHANICAL

8. Check the engine oil level and replenish to the

specified level if required.

9. Start the engine and check for oil leakage from the

main oil filter.

FUEL SYSTEM

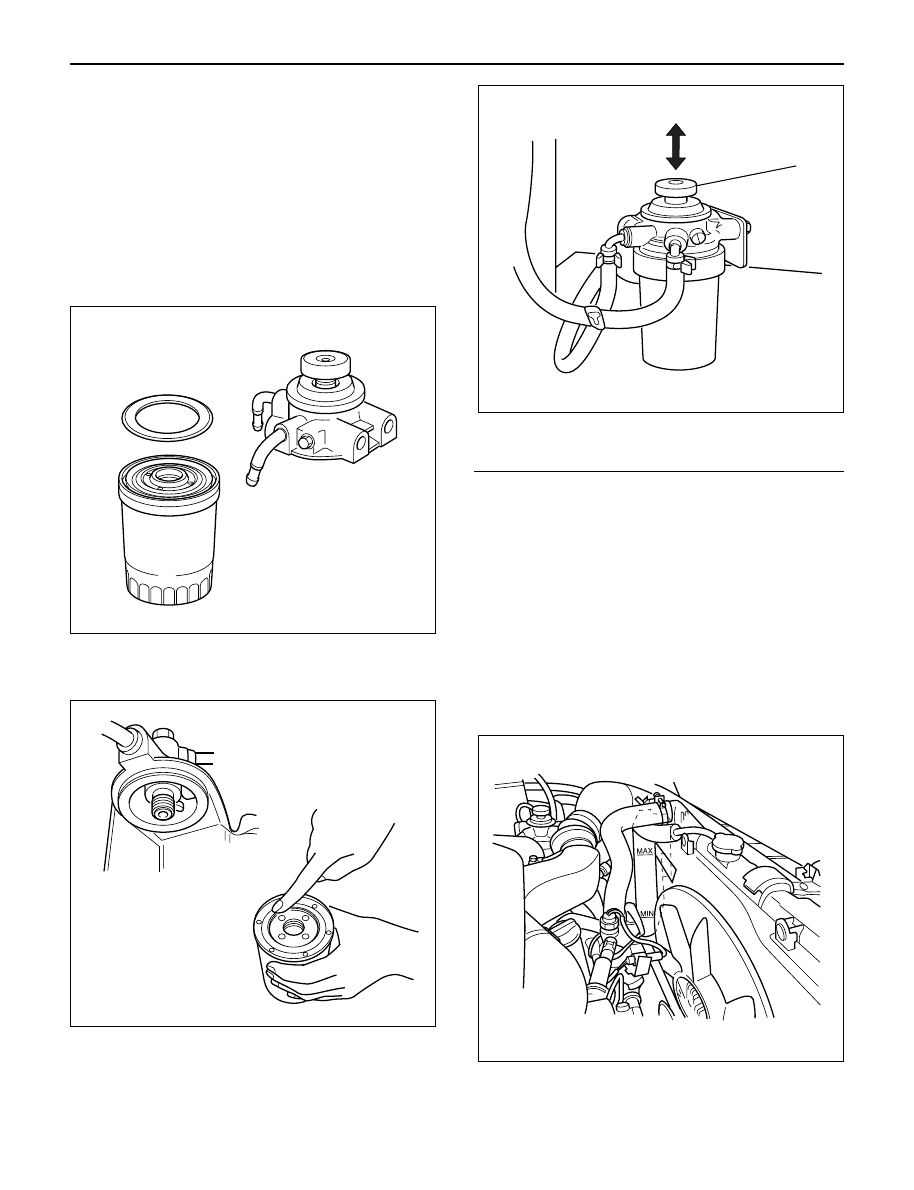

Fuel filter

Replacement Procedure

1. Loosen the used fuel filter by turning it

counterclockwise with the filter wrench.

Filter Wrench : 5-8840-0203-0

2. Clean the filter cover fitting faces.

This will allow the new fuel filter to seat properly.

3. Apply a light coat of engine oil to the O-ring.

4. Turn the fuel filter until the sealing face comes in

contact with the O-ring.

5. Turn the fuel filter with a filter wrench 2/3 of a turn

until sealed.

Filter Wrench: 5-8840-0203-0

Legend

(1) Priming pump

6. Operate the priming pump until the air is discharged

completely from fuel system.

NOTE: The use of an Isuzu genuine fuel filter is

strongly recommended.

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator

reserve tank as necessary.

If the coolant level falls below the “‘MIN” line, carefully

check the cooling system for leakage. Then add

enough coolant to bring the level up to the “MAX” line.

NOTE: Do not overfill the reserve tank.

012RW112

012RW078

1

012RW111

012RW080