Content .. 2364 2365 2366 2367 ..

Opel Frontera UBS. Manual - part 2366

6E–500

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

Accelerator Position Sensor

Replacement

CAUTION: Remove the Accelerator (A) pedal

assembly as a unit to have it serviced. Do not remove

the Accelerator Position (AP) sensor on the A pedal.

If the AP sensor is removed for emergency cause,

refer to following items as necessary.

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical harness from the AP sensor.

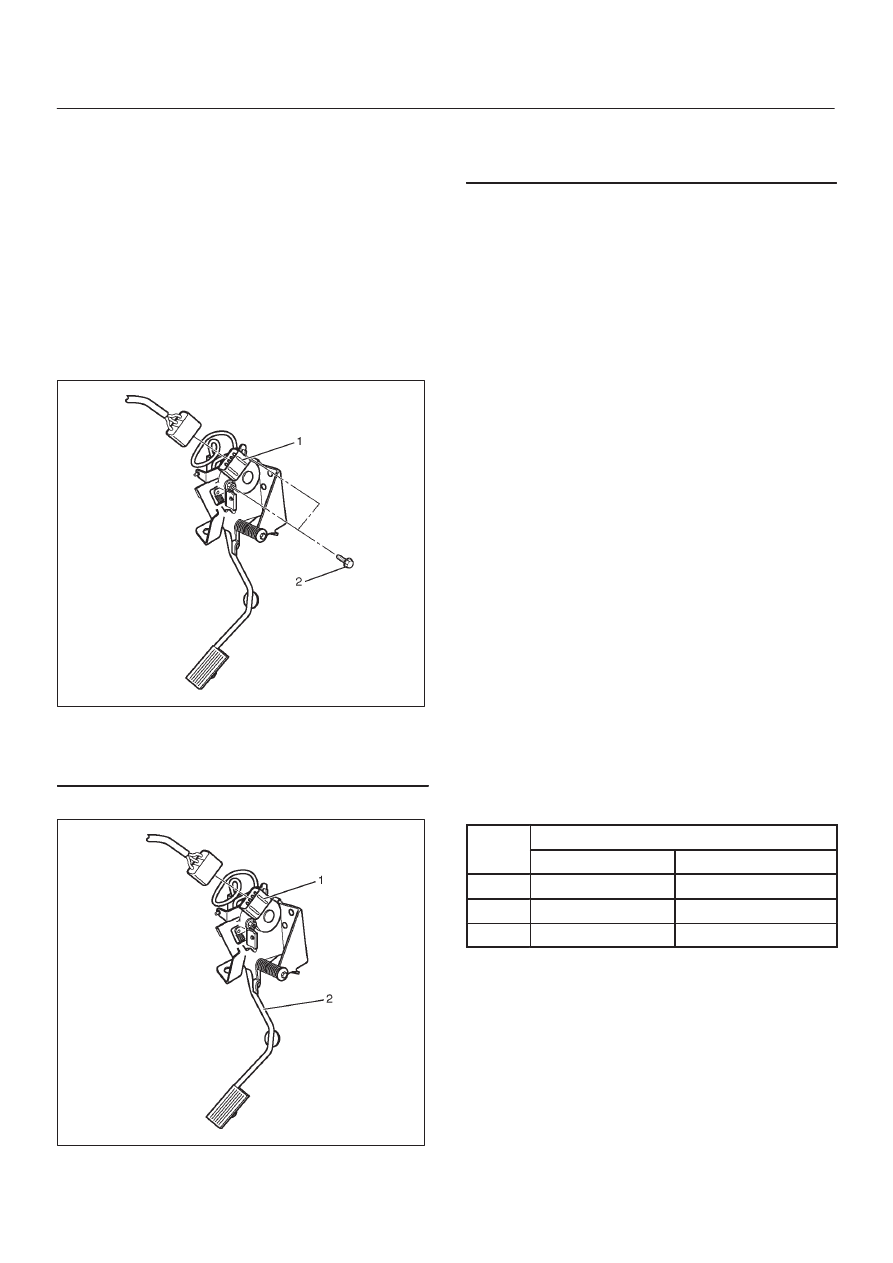

060R200233

Legend

(1) AP Sensor

(2) A Pedal Assembly

3. Remove the AP sensor.

060R200235

Legend

(1) AP Sensor

(2) AP Screw

4. Remove all grease residues from the Accelerator

Position Sensor mounting

5. Clean all connector pins with contact cleaner. Use

LOCTITE

/ Permatex Electrical Contact Cleaner, or

equivalent.

NOTE: Do not use brake cleaner or carburetor spray.

Installation Procedure

1. Install the accelerator position (AP) sensor to bolts

with accelerator (A) pedal.

2. Connect the connector to AP sensor.

3. Install the negative battery cable.

Accelerator Position Sensor

Adjustment

AP sensor is controled three maltiple control system, and

adjust the idle position and WOT position are between A

and B for AP sensor 1, AP sensor 2, and AP sensor 3.

Refer to

“How to adjust for AP sensor”.

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical harness from the AP sensor.

How To Adjust For AP Sensor

1. Connect the Tech 2 to DLC on vehicle.

2. Ignition “ON,” engine “OFF.”.

3. Display the APS date list. Check the following item for

AP position (%).

AP position (%)

Idle position A

WOT position B

APS1

11 – 15%

85 – 89%

APS2

85 – 89%

11 – 15%

APS3

85 – 89%

32 – 36%