Content .. 1319 1320 1321 1322 ..

Opel Frontera UBS. Manual - part 1321

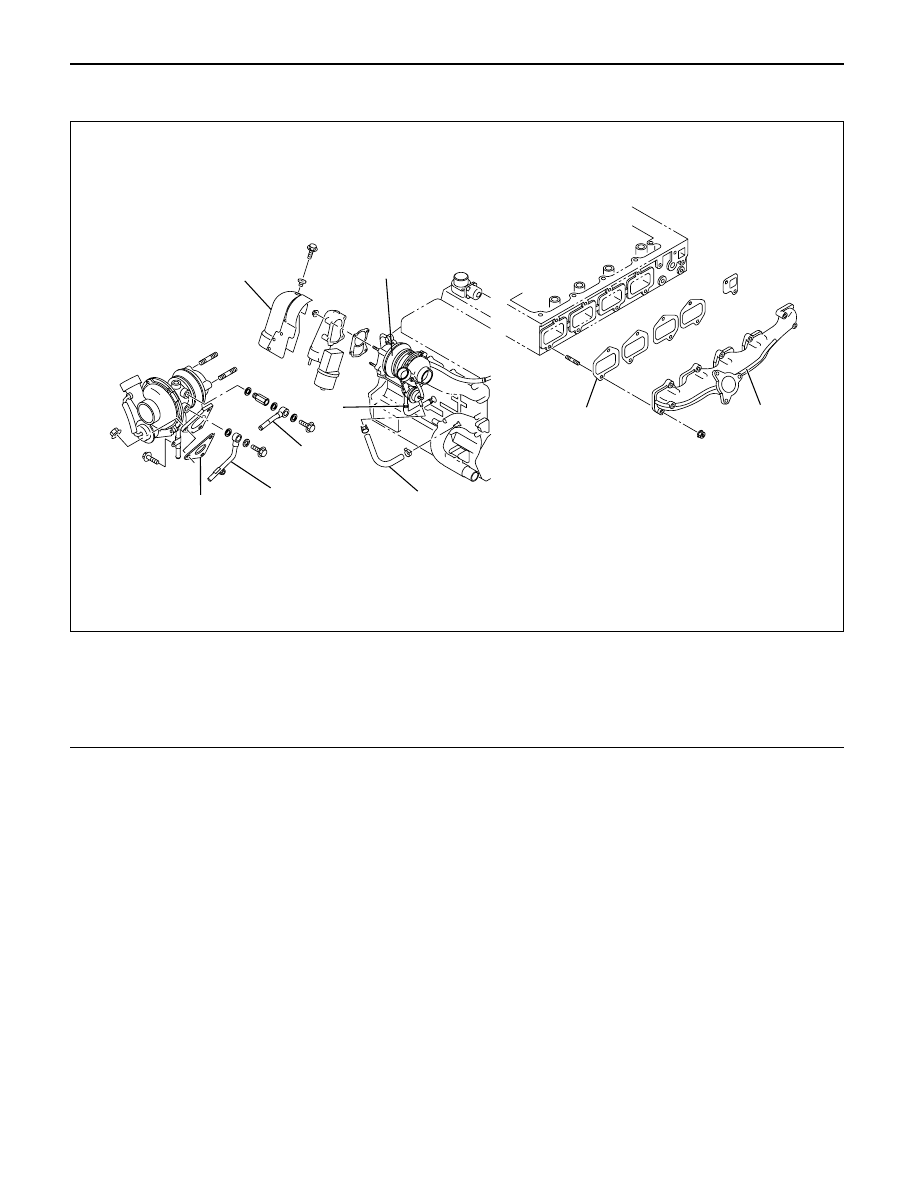

6A – 34 ENGINE MECHANICAL

EXHAUST MANIFOLD

REMOVAL

1. Remove the hose from both turbocharger outlet and

intake manifold inlet side, then remove intercooler

assembly.

2. Loosen belt tensioner, remove A/C compressor

assembly.

3. Remove heat protector from turbocharger.

4. Remove water hoses and oil pipes from

turbocharger.

5. Remove turbocharger assembly from exhaust

manifold.

6. Remove exhaust manifold fixing nuts, then remove

exhaust manifold.

INSTALLATION

1. Install gasket on the exhaust manifold and tighten

to the specified torque.

Torque : 30 N·m (3.1 kg·m/22 lb ft)

2. Install turbocharger on the exhaust manifold.

Torque : 27 N·m (2.8 kg·m/20.2 lb ft)

3. Install water hoses and oil pipes.

4. Install heat protector to turbocharger.

Torque : 9 N·m (0.9 kg·m/6.5 lb ft)

5. Install A/C compressor assembly and readjust belt

tensioner.

6. Install the intercooler assembly in the normal

position.

Connect both hoses to turbocharger and intake

manifold.

9

8

7

5

6

3

2

1

4

025RW023

Legend

(1)

Exhaust Manifold

(2)

Gasket

(3)

Turbocharger Assembly

(4)

Water Hose

(5)

Water Hose

(6)

Heat Protector

(7)

Oil Pipe

(8)

Oil Pipe

(9)

Gasket