Content .. 1320 1321 1322 1323 ..

Opel Frontera UBS. Manual - part 1322

6A – 38 ENGINE MECHANICAL

1. Cylinder head bolts for damaged threads or

stretching and damaged heads caused by improper

use of tools.

CAUTION: Suspected bolts must be replaced.

2. Cylinder head for cracks, especially between valve

seats and in the exhaust ports.

3. Cylinder head deck for corrosion, sand particles in

head and porosity.

CAUTION: Do not attempt to weld the cylinder

head. Replace it.

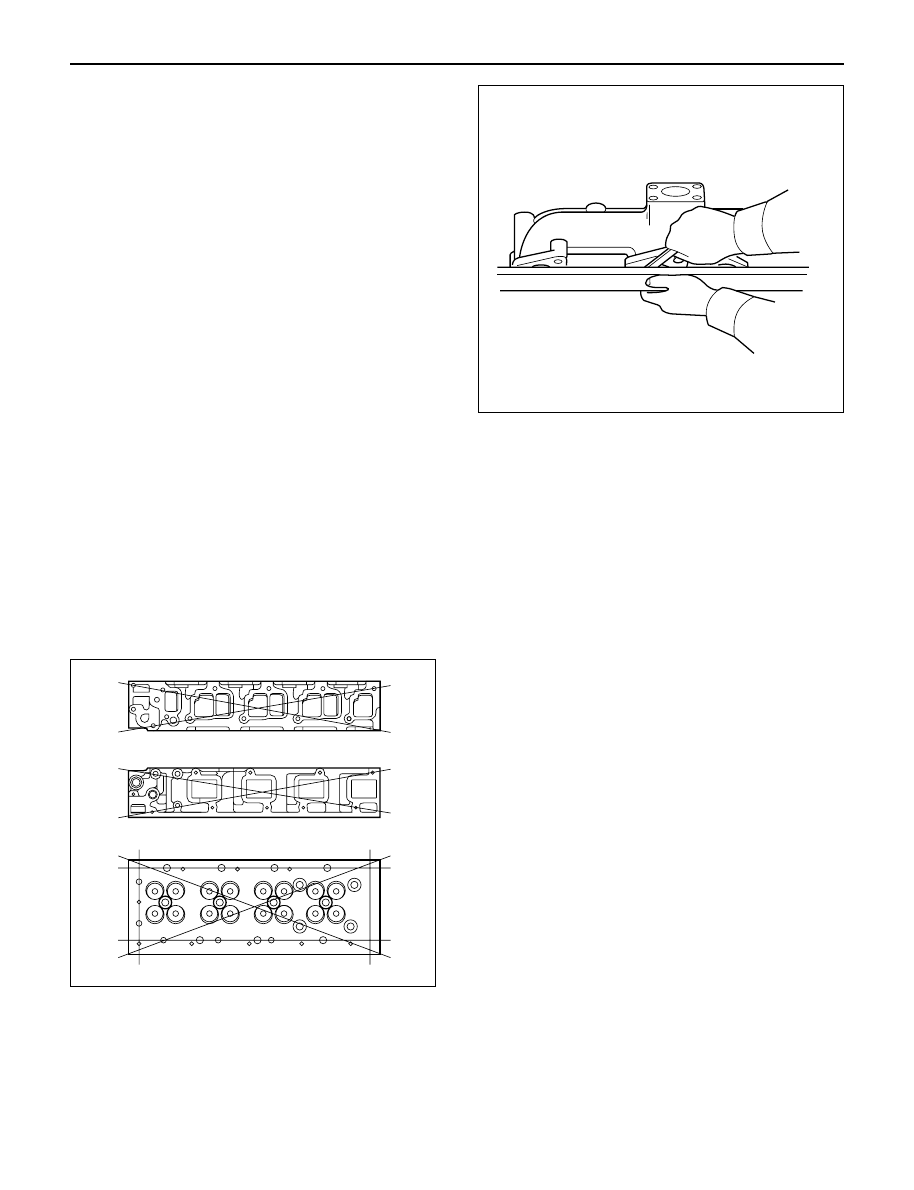

4. Cylinder head lower surface for flatness.

Use a straight edge and a feeler gauge to measure

the cylinder head lower surface warpage.

If the measured values exceed the specified limit,

the cylinder head must be replaced.

Cylinder Head Lower Face Warpage:

Standard: 0.075 mm (0.0029 in) or less

Limit: 0.50 mm (0.0197 in)

Cylinder Head Height:

Standard: 95 mm (3.740 in)

5. Water jacket sealing plugs seating surfaces.

6. Use a straight edge and a feeler gauge to measure

the manifold cylinder head fitting face warpage.

If the measured values exceed the specified limit,

the manifold must be replaced.

Exhaust Manifold Warpage:

Standard: 0.05 mm (0.0020 in) or less

Limit: 0.20 mm (0.0079 in)

CAUTION: Do not attempt to weld the cylinder

head. Replace it.

REASSEMBLY

1. Cylinder Head

•

Refer to “Cylinder head”.

2. Glow Plug and Glow Plug Connector

•

Tighten glow plugs.

Torque: 15 N·m (1.5 kg·m/11 lb ft)

011RW006

012RW053