Opel Frontera UBS. Manual - part 22

1A – 4 HEATING AND VENTILATION

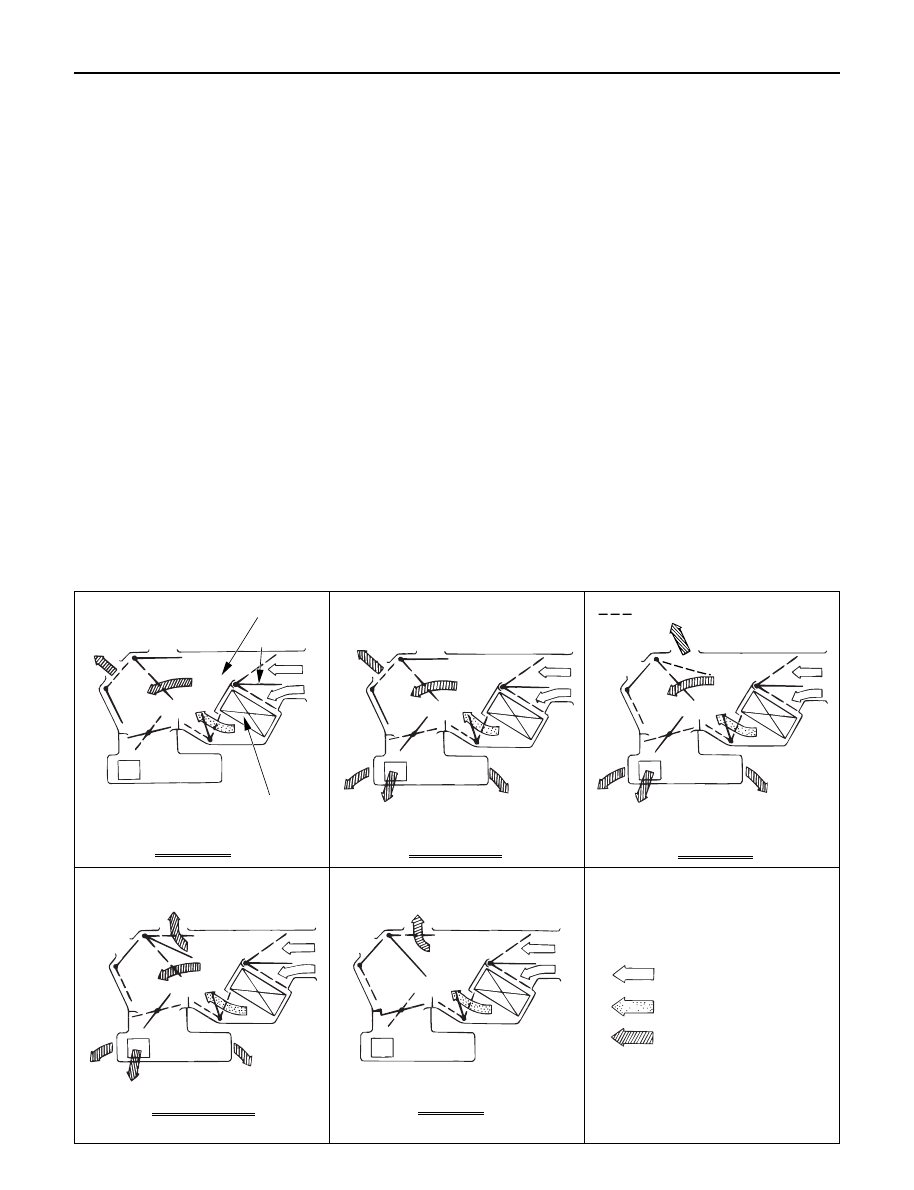

AIR SELECT KNOB

The air selector knob allows you to direct heated air

into the passenger compartment through different

outlets.

1.

Vent - In this position, air is discharged from

the upper air outlet. Air quantity is controlled

by the fan control knob.

2.

Bi-Level - In this position, air flow is divided

between the upper air outlets and the foot air

outlets, with warmer air delivered to the floor

outlets than the air delivered to the upper air

outlets.

3.

Foot - In this position, air flow is delivered to

the foot while sending approx. 30% of total

amount of air to the windshield

4.

Def/Foot - In this position, air flow is delivered

to the foot, while sending approx. 40% of total

amount of air to the windshield.

5.

Defrost - In this position, most of the air is

delivered to the windshield and a small

amount is delivered to the side windows.

Moving the air source select lever to the “CIRC”

position provides quickest heat delivery by closing

the blower assembly mode door. In this position,

outside air is not delivered to the passenger

compartment.

AIR SOURCE SELECT LEVER

The intake of outside air and the circulation of inside

air are controlled by sliding this lever left or right.

FAN CONTROL KNOB

This knob controls the blower motor speed to

regulate the amount of air delivered to the defrost,

foot, and ventilation ducts:

1.

Low

2.

Medium Low

3.

Medium High

4.

High

TEMPERATURE CONTROL KNOB

When the temperature control knob is in the

“COLD” position, the air mix door closes to block

the flow of air to the heater core.

When the temperature control knob is in the

“HOT” position, the air mix door opens to allow air

to pass through the heater core and heat the

passenger compartment.

Placing the knob in an intermediate position will

cause a lesser or greater amount of air to reach the

heater core. In this mode the passenger compart-

ment temperature can be regulated.

Heater core

Heater unit

TO VENT OUTLET

Air mix door

VENT MODE

TO FOOT

TO VENT OUTLET

BI-LEVEL MODE

FOOT MODE

TO FOOT OUTLET

TO DEF OUTLET(LHD)

DEF/FOOT MODE

TO FOOT OUTLET

TO DEF OUTLET

DEF MODE

TO DEF OUTLET

: COLD AIR

: HOT AIR

: TEMP.CONTROLLED AIR