Content .. 1347 1348 1349 1350 ..

Opel Frontera UE. Manual - part 1349

4C–18

DRIVE SHAFT SYSTEM

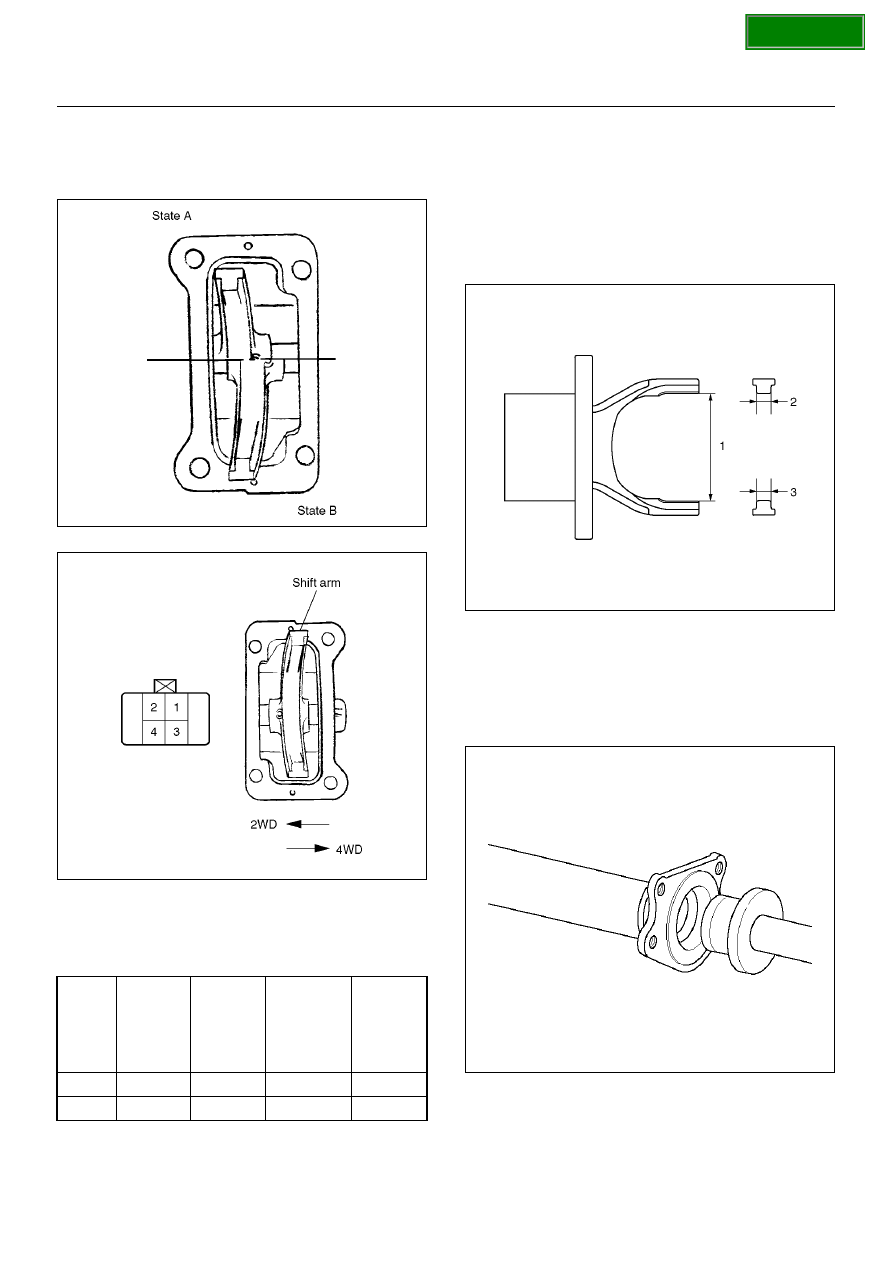

Actuator

Check and see that there is no damage, cracking, or

other abnormality.

Functional Check

412RY00041

412RY00009

Wake sure of function with boltage (12V) applied to

terminal 3, 4 and set the tester to terminal 1, 2 in

accordance with the table below.

If there is an abnormality, replace the actuator as an

assembly.

NOTE: Be careful not to permit the entry of water or

dust into of the actuator.

Dimentional Check

Measure illustrated sizes 1, 2, and 3.

Limit

1=64.1mm (2.52in)

2=6.7 mm (0.26 in)

3=6.7 mm (0.26 in)

412RY00010

Reassembly

1. Install the new oil seal which has been immersed in

differential gear oil, by using an oil seal installer 5–

8840–2407–0 and grip 5–8840–0007–0.

412RW034

State

Trminal 3 Trminal 4

Electric

circuit

between

terminal 1

& 2

Function

A

+12V

Ground

OK

2WD

B

Ground

+12V

NONE

4WD