Content .. 1008 1009 1010 1011 ..

Opel Frontera UE. Manual - part 1010

7A–64

AUTOMATIC TRANSMISSION (4L30–E)

241RW009

241RS004

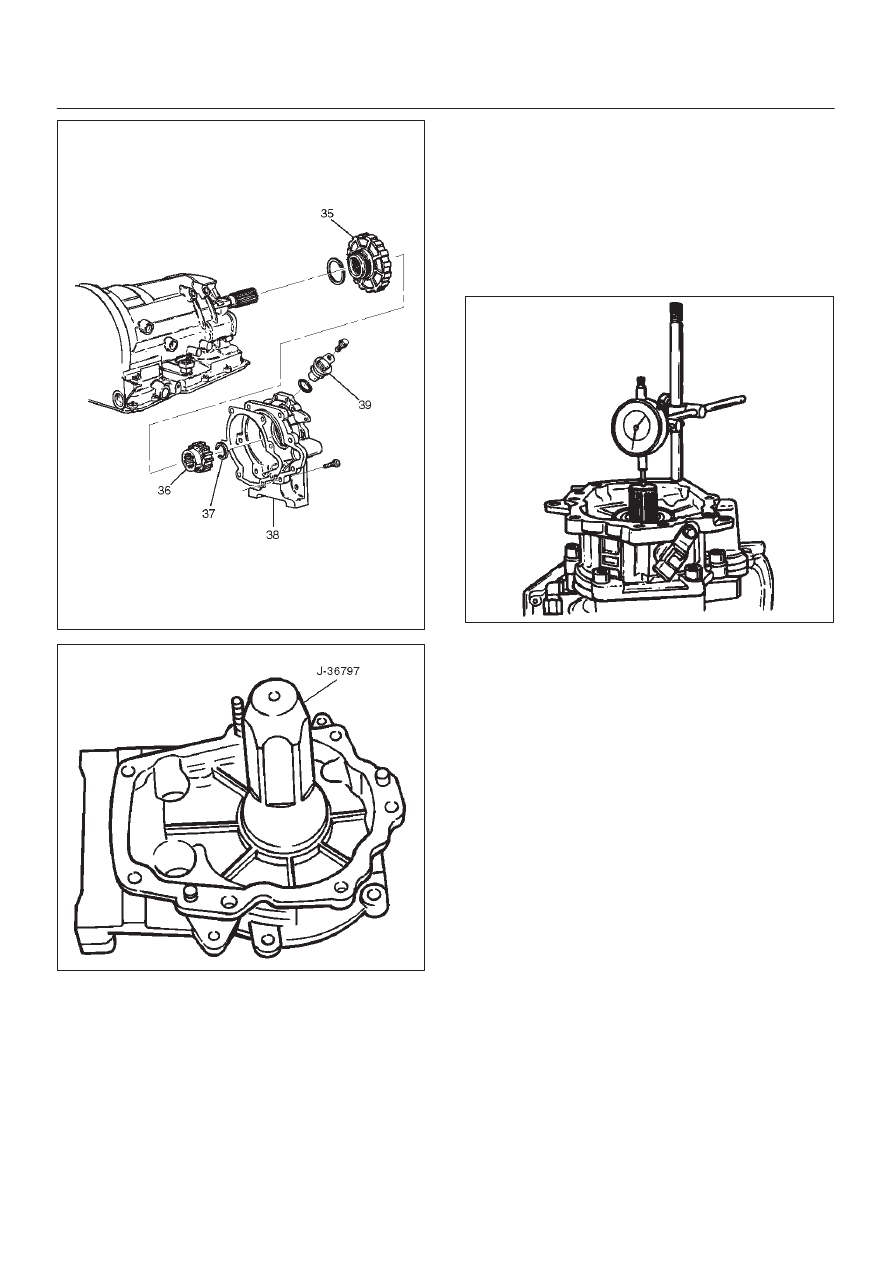

43. Main case end play measurement

1. Attach axial play checking tool on the extension

housing and set indicator to zero on output shaft.

2. Manually push output shaft upwards.

End play: 0.36mm – 0.80mm (0.014 in – 0.031in)

3. Remove axial play checking tool.

4. If end play is not correct, repeat selective washer

selection.

241RS005

44. Inspect servo piston seal ring. Replace if necessary.

D

Ensure brake band is correctly positioned. Rotate

output shaft if necessary.

D

Install J–38428 servo piston fitter in servo bore.

D

Install apply rod (40), round end toward band, return

spring (41) and piston assembly (42).

45. Install the J–23075 servo spring compressor with

offset to rear of case.

D

Compress servo piston seal ring, using fitter while

tightening the tool screw.

D

Install servo piston retaining ring (43).

D

Remove tool.

D

Adjust the brake band by tightening the servo

adjusting screw to 4.5 N·m torque. Be certain the

lock nut is loose, then back-off the screw five turns

exactly. Hold piston sleeve with wrench and tighten

lock nut to 18.5 N·m torque. Be certain the adjusting

screw does not turn.