Content .. 1007 1008 1009 1010 ..

Opel Frontera UE. Manual - part 1009

7A–60

AUTOMATIC TRANSMISSION (4L30–E)

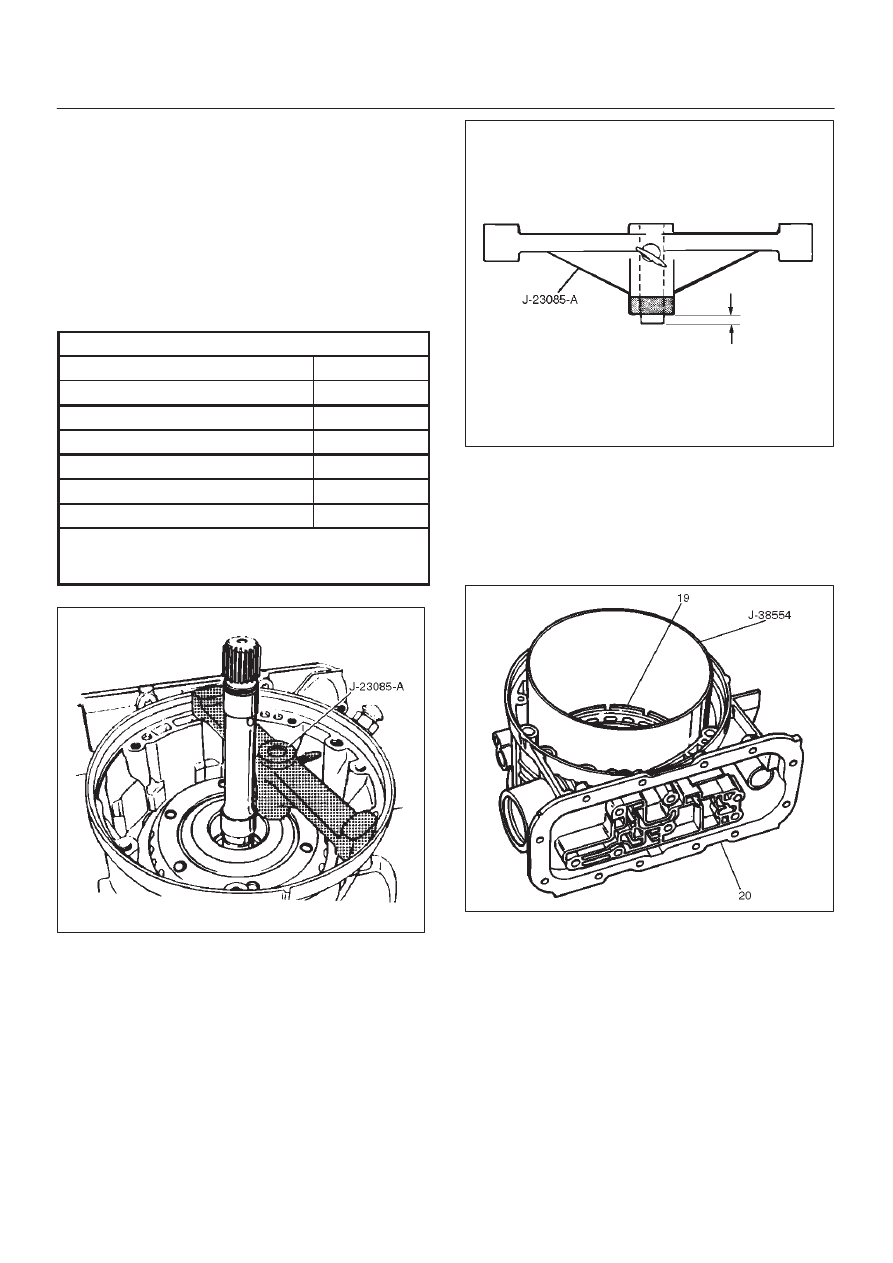

22. Second clutch end play measurement

1. Install the J–23085–A selective washer gauging

tool (with spacer ring) on the case flange and

against the intermediate shaft.

2. Position the inner shaft of the gauging tool against

the thrust surface of the second clutch hub.

3. Tighten thumb screw. Remove the tool.

4. Fit the spacer ring on the inner shaft of the tool.

5. Measure the gap and select appropriate washer

as shown in the chart.

Selective Thrust Washer

Gap: mm(in)

Color

1.53 – 1.63 (0.060 – 0.064)

Yellow

1.72 – 1.82 (0.068 – 0.072)

Red

1.91 – 2.01 (0.075 – 0.079)

Black

2.10 – 2.20 (0.083 – 0.087)

Natural

2.29 – 2.39 (0.090 – 0.094)

Green

2.48 – 2.58 (0.098 – 0.102)

Blue

FOLLOWING THE PROCEDURE SHOULD

RESULT IN FINAL END–PLAY FROM 0.36 mm TO

0.79 mm (0.014 in TO 0.031 in)

247RS003

247RS004

23. Inspect fourth clutch piston seals and replace if

necessary.

D

Lubricate J–38554 fourth clutch piston fitter and

install it on fourth clutch piston (19).

D

Install fourth clutch piston (19) in adapter case (20).

D

Remove fitter.

252RS003

24. Install retainer and spring assembly (22) into fourth

clutch piston (21).

25. Install snap ring (23) in adapter case.

D

Install J–23327 and J–23327–90 fourth clutch

spring compressor.

D

Seat snap ring in groove.

D

Remove compressor.