Content .. 1006 1007 1008 1009 ..

Opel Frontera UE. Manual - part 1008

7A–56

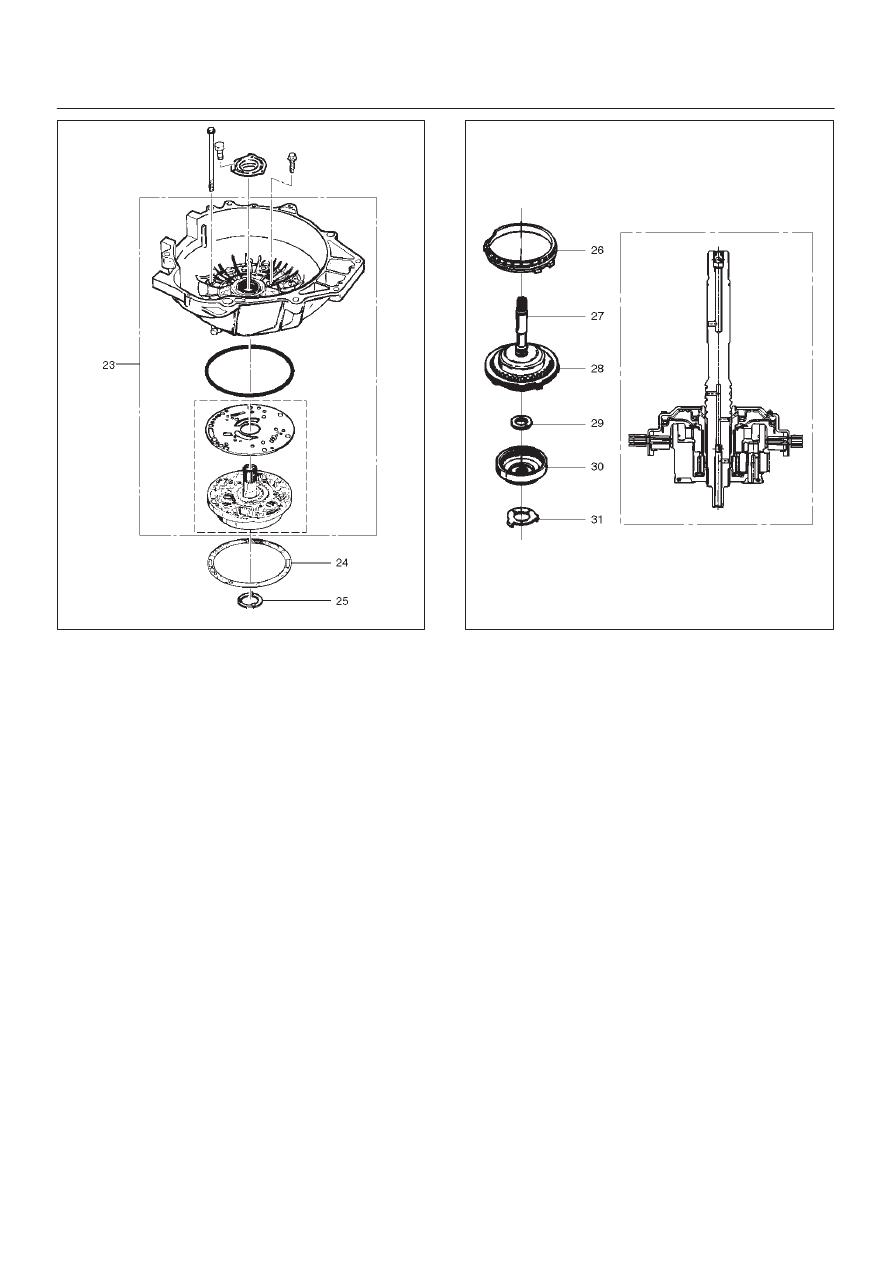

AUTOMATIC TRANSMISSION (4L30–E)

241RW004

24. Remove fourth clutch retainer (26).

25. Grasp turbine shaft and lift out the overrun clutch

housing assembly (27) and fourth clutch plates (28).

26. Remove thrust bearing assembly (29).

27. Remove overdrive internal gear (30).

28. Remove thrust washer (31).

252RS001

29. Remove adapter case and center support assembly

(with fourth clutch piston) (32).

30. Remove seal ring (33).

31. Remove selective thrust washer (34) and two O-ring

seals (35) from main case.

32. Use J–23327 and J–23327–90 compressor to

compress the fourth clutch spring retainer and

springs (37).

D

Release snap ring (36) from groove.

D

Remove clutch compressor and snap ring (36).

33. Remove retainer and spring assembly (37).

34. Insert two converter housing/main case screws to

hold adapter case while pulling out fourth clutch

piston (38).

D

Remove fourth clutch piston assembly (38) from the

adapter case.

D

Remove converter housing/main case screws.

35. Grasp intermediate shaft, twist and pull out the

second and third clutch drum assemblies with reverse

clutch plates while holding onto output shaft (39).