Nissan Frontier D40. Manual - part 714

GW-24

< ON-VEHICLE REPAIR >

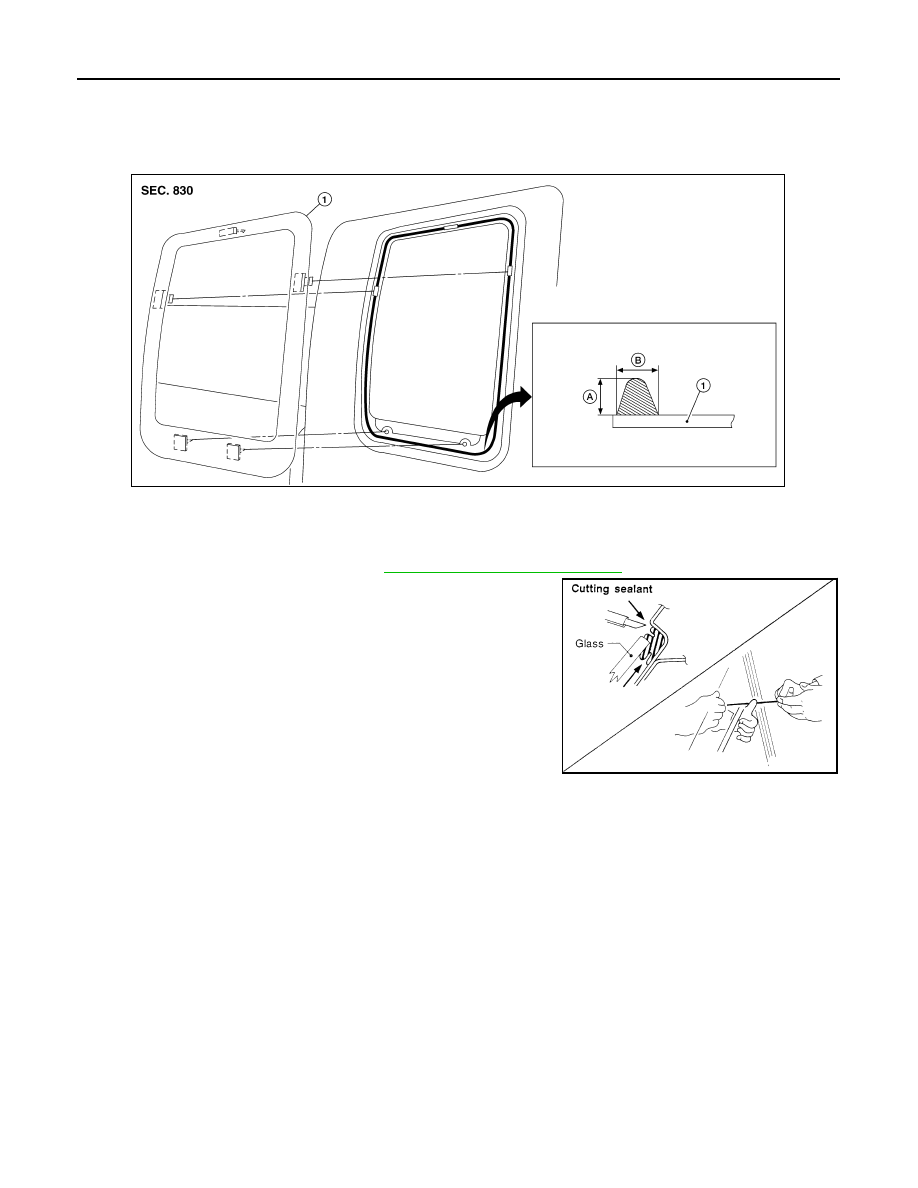

SIDE WINDOW GLASS

SIDE WINDOW GLASS

Removal and Installation

INFOID:0000000005274597

REMOVAL

1.

Remove the rear door finisher. Refer to

INT-14, "Removal and Installation"

.

• Remove glass using piano wire or power cutting tool and an

inflatable pump bag.

• If the window glass is to be reused, mark the body and the

glass with mating marks.

WARNING:

When cutting the glass from the vehicle, always wear safety

glasses and heavy gloves to help prevent glass splinters from

entering your eyes or cutting your hands.

CAUTION:

• When the side window glass is to be reused, do not use a cut-

ting knife or power cutting tool.

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its edge. Small chips may develop into cracks.

INSTALLATION

Installation is in the reverse order of removal.

• Use a genuine NISSAN Urethane Adhesive Kit (if available) or equivalent and follow the instructions fur-

nished with it.

• While the urethane adhesive is curing, open a door window. This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• Check gap along bottom to confirm that glass does not contact sheet metal.

• Inform the customer that the vehicle should remain stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, immediately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the glass in case of an accident.

CAUTION:

1.

Side window glass

A.

12.0 mm (0.47 in)

B.

7.0 mm (0.28 in)

WIIA0943E

SBF034B