Nissan Frontier D40. Manual - part 574

EM-28

< ON-VEHICLE REPAIR >

[QR25DE]

INTAKE MANIFOLD

4.

Remove air cleaner case, air cleaner filter and air duct and resonator assembly. Refer to

5.

Disconnect water hoses from electric throttle control actuator.

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

6.

Remove mass air flow sensor from intake manifold.

CAUTION:

Handle the mass air flow sensor with care:

• Do not shock it.

• Do not disassemble it.

• Do not touch the internal sensor.

7.

Remove quick connector cap, and disconnect quick connector

at the engine side. Refer to

.

8.

Remove air duct. Refer to

9.

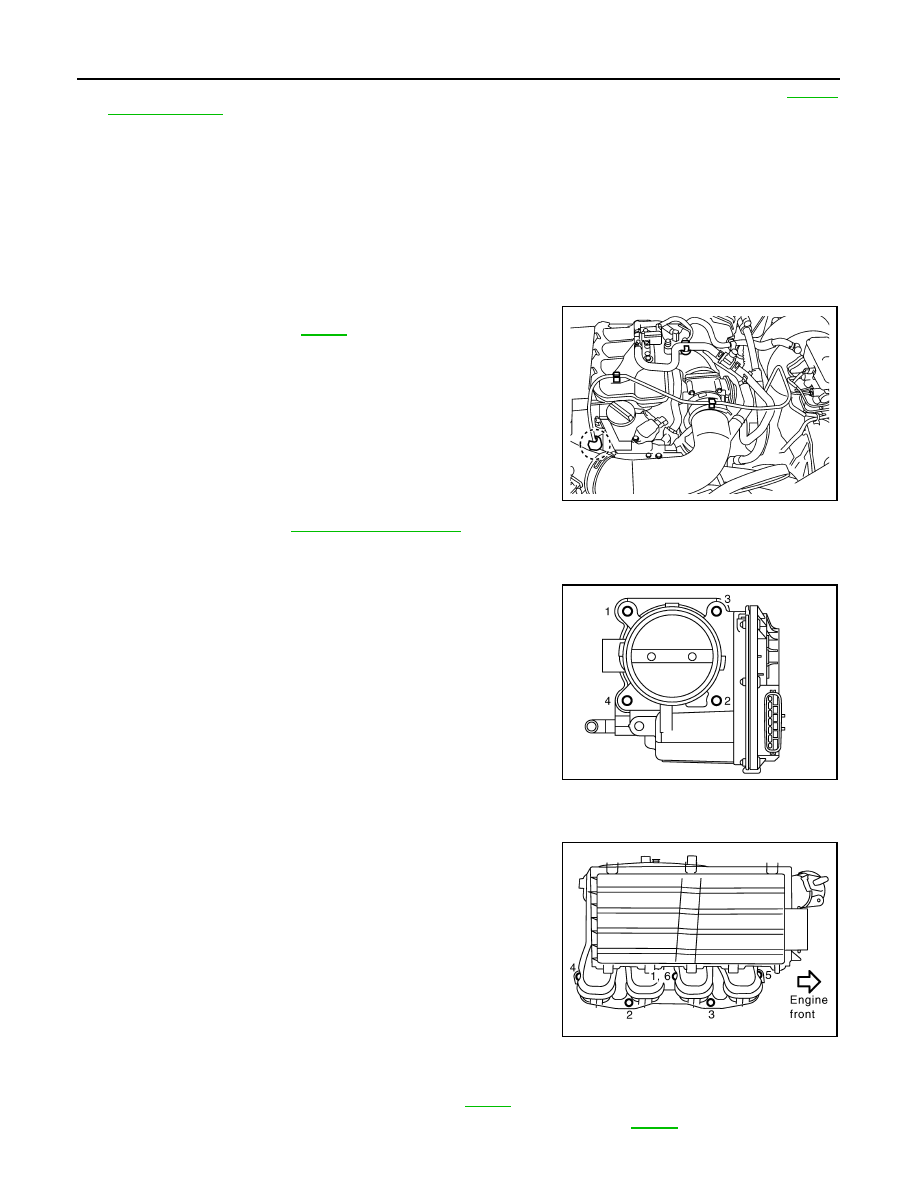

Remove electric throttle control actuator as follows:

a.

Disconnect harness connector.

b.

Loosen bolts in reverse order as shown, and remove electric

throttle control actuator and gasket.

CAUTION:

• Handle carefully to avoid any shock to electric throttle

control actuator.

• Do not disassemble.

10. Disconnect harness, vacuum hoses and PCV hoses from intake manifold, and move them aside.

11. Remove intake manifold support.

12. Loosen nuts and bolts in reverse order as shown, and remove

intake manifold, fuel tube protector and gasket.

CAUTION:

• Cover engine openings to avoid entry of foreign materi-

als.

• Do not disassemble intake manifold.

NOTE:

Disregard No. 6 when loosening.

13. Remove EVAP canister purge volume control solenoid valve and vacuum hose adapter from intake mani-

fold, if necessary.

14. Disconnect sub-harness from fuel injector. Refer to

.

15. Remove fuel tube and fuel injector assembly from intake manifold. Refer to

LBIA0450E

PBIC2987E

PBIC2988E