Nissan Frontier D40. Manual - part 502

P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

EC-699

< COMPONENT DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

4.

Also check harness for short to ground and short to power.

OK or NG

OK (With CONSULT-III)>>GO TO 4.

OK (Without CONSULT-III)>>GO TO 5.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-III

1.

Reconnect all harness connectors disconnected.

2.

Start engine.

3.

Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode with CONSULT-III. Check that engine speed var-

ies according to the valve opening.

OK or NG

OK

>> GO TO 6.

NG

>> GO TO 5.

5.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

EC-699, "Component Inspection"

OK or NG

OK

>> GO TO 6.

NG

>> Replace EVAP canister purge volume control solenoid valve.

6.

CHECK INTERMITTENT INCIDENT

GI-46, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000005273667

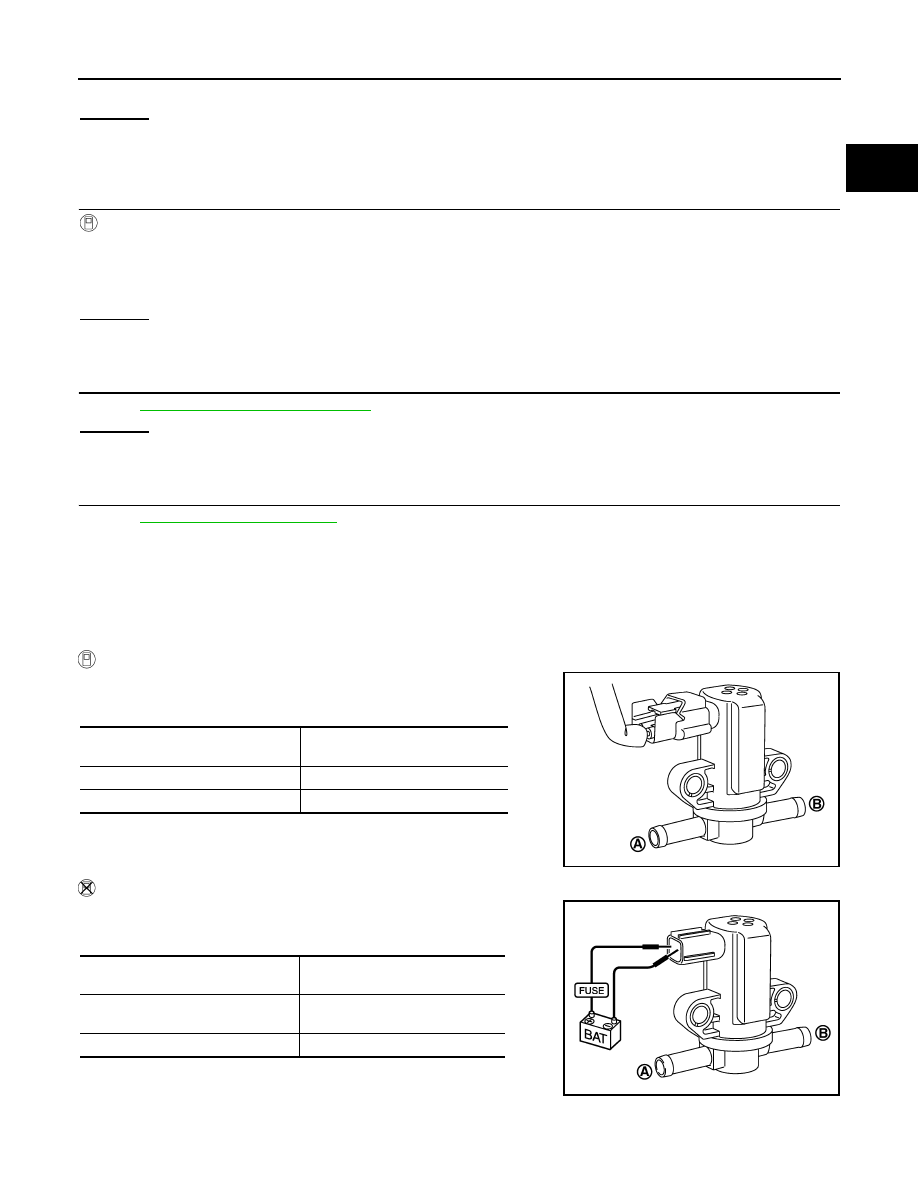

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-III

Check air passage continuity of EVAP canister purge volume control

solenoid valve under the following conditions.

Without CONSULT-III

Check air passage continuity of EVAP canister purge volume control

solenoid valve under the following conditions.

Condition

(PURG VOL CONT/V value)

Air passage continuity

between (A) and (B)

100%

Yes

0%

No

PBIB2058E

Condition

Air passage continuity

between (A) and (B)

12V direct current supply between

terminals 1 and 2

Yes

No supply

No

PBIB2059E