Nissan Frontier D40. Manual - part 500

P0442 EVAP CONTROL SYSTEM

EC-691

< COMPONENT DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

OK or NG

OK

>> GO TO 25.

NG

>> Replace fuel level sensor unit.

25.

CHECK INTERMITTENT INCIDENT

GI-46, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000005273657

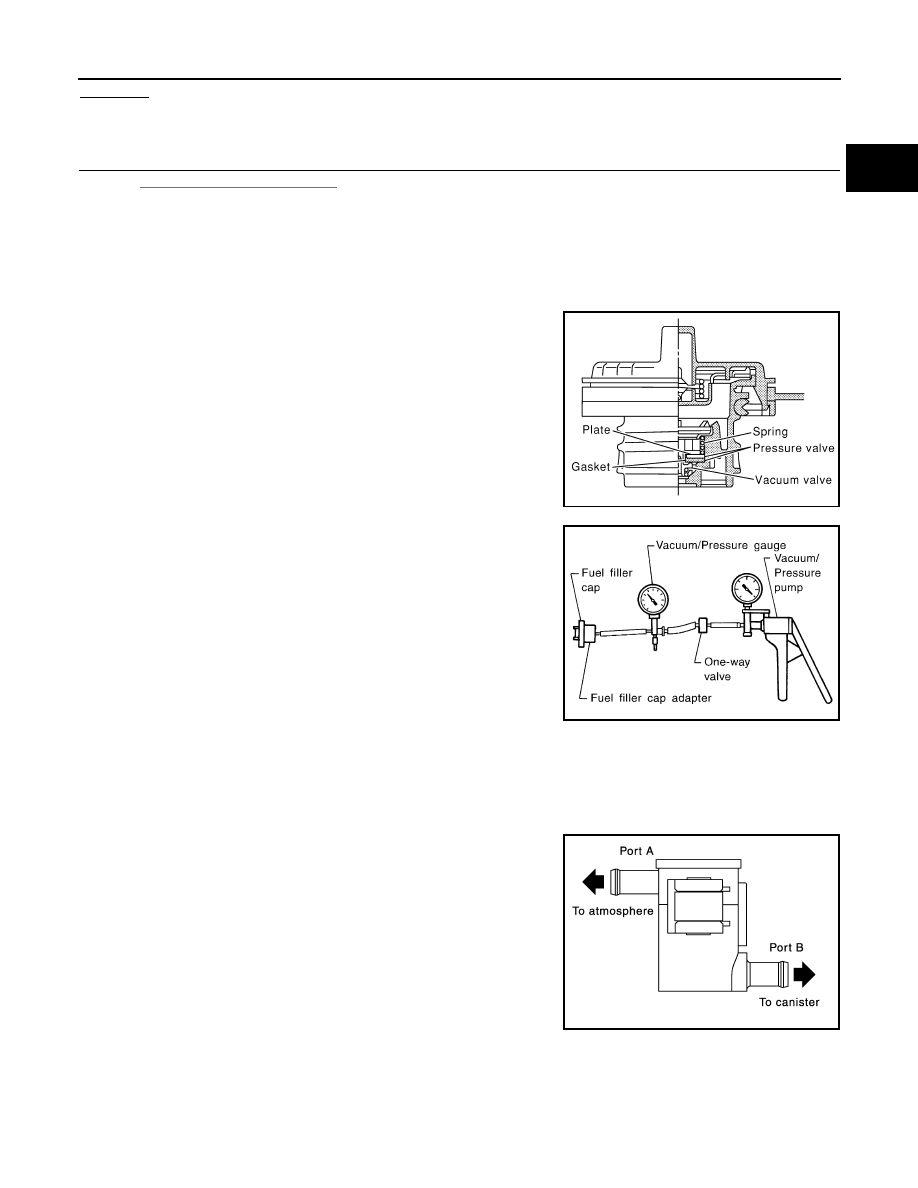

FUEL TANK VACUUM RELIEF VALVE (BUILT INTO FUEL FILLER CAP)

1.

Wipe clean valve housing.

2.

Check valve opening pressure and vacuum.

3.

If out of specification, replace fuel filler cap as an assembly.

CAUTION:

Use only a genuine fuel filler cap as a replacement. If an incor-

rect fuel filler cap is used, the MIL may illuminate.

DRAIN FILTER

1.

Check visually for insect nests in the drain filter air inlet.

2.

Check visually for cracks or flaws in the appearance.

3.

Check visually for cracks or flaws in the hose.

4.

Blow air into port A and check that it flows freely out of port B.

5.

Block port B.

6.

Blow air into port A and check that there is no leakage.

7.

If NG, replace drain filter.

SEF445Y

Pressure:

15.3 - 20.0 kPa (0.156 - 0.204 kg/cm

2

, 2.22 -

2.90 psi)

Vacuum:

−

6.0 to

−

3.3 kPa (

−

0.061 to

−

0.034 kg/cm

2

,

−

0.87 to

−

0.48 psi)

SEF943S

PBIB3641E