Nissan Frontier D40. Manual - part 498

P0441 EVAP CONTROL SYSTEM

EC-683

< COMPONENT DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

1.

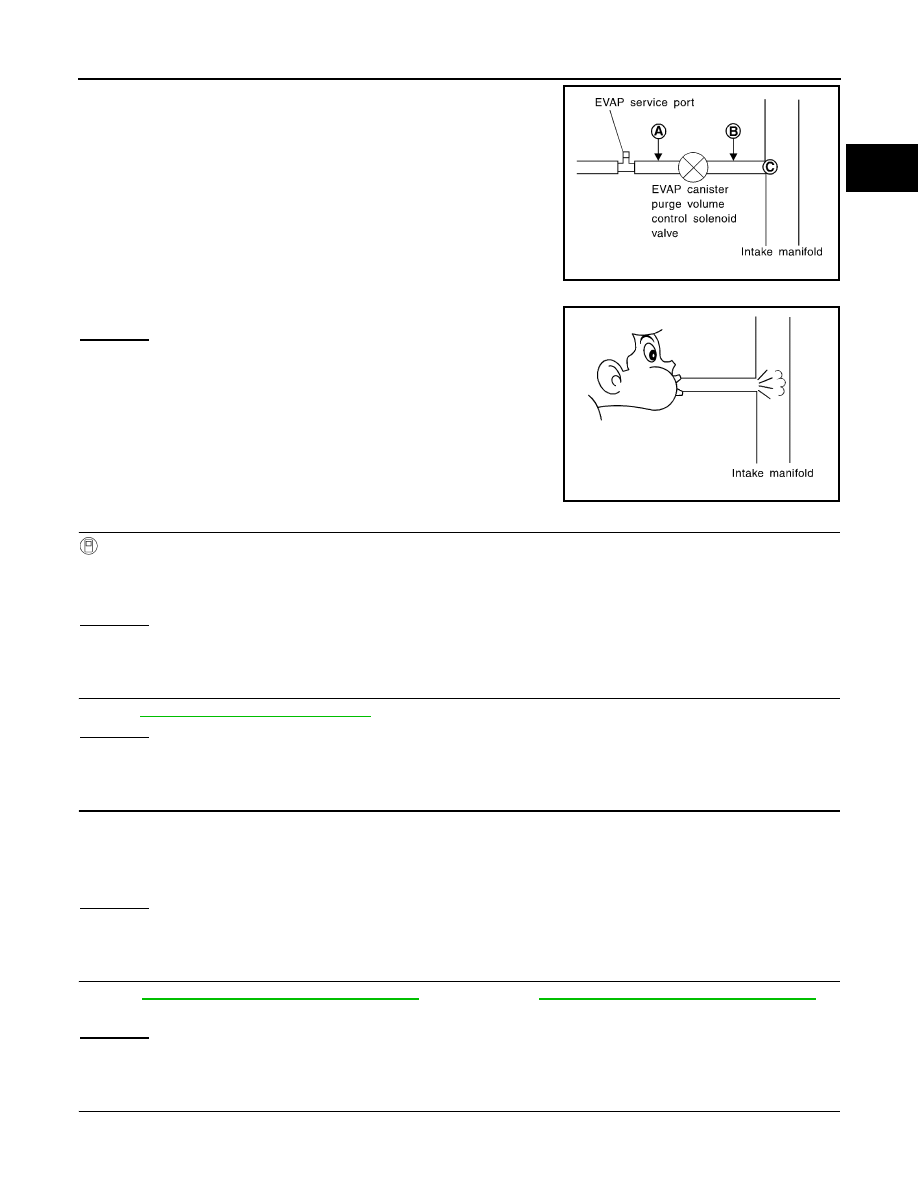

Disconnect purge hoses connected to EVAP service port (A)

and EVAP canister purge volume control solenoid valve (B).

2.

Blow air into each hose and EVAP purge port (C).

3.

Check that air flows freely.

OK or NG

OK (With CONSULT-III)>>GO TO 6.

OK (Without CONSULT-III)>>GO TO 7.

NG

>> Repair or clean hoses and/or purge port.

6.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-III

1.

Start engine.

2.

Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode with CONSULT-III. Check that engine speed var-

ies according to the valve opening.

OK or NG

OK

>> GO TO 8.

NG

>> GO TO 7.

7.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

EC-699, "Component Inspection"

OK or NG

OK

>> GO TO 8.

NG

>> Replace EVAP canister purge volume control solenoid valve.

8.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1.

Disconnect EVAP control system pressure sensor harness connector.

2.

Check connectors for water.

OK or NG

OK

>> GO TO 9.

NG

>> Replace EVAP control system pressure sensor.

9.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR FUNCTION

Refer to

EC-712, "DTC Confirmation Procedure"

EC-716, "DTC Confirmation Procedure"

for

P0453.

OK or NG

OK

>> GO TO 10.

NG

>> Replace EVAP control system pressure sensor.

10.

CHECK RUBBER TUBE FOR CLOGGING

1.

Disconnect rubber tube connected to EVAP canister vent control valve.

SEF367U

SEF368U

Water should not exist.