Nissan Frontier D40. Manual - part 488

P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

EC-643

< COMPONENT DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2.

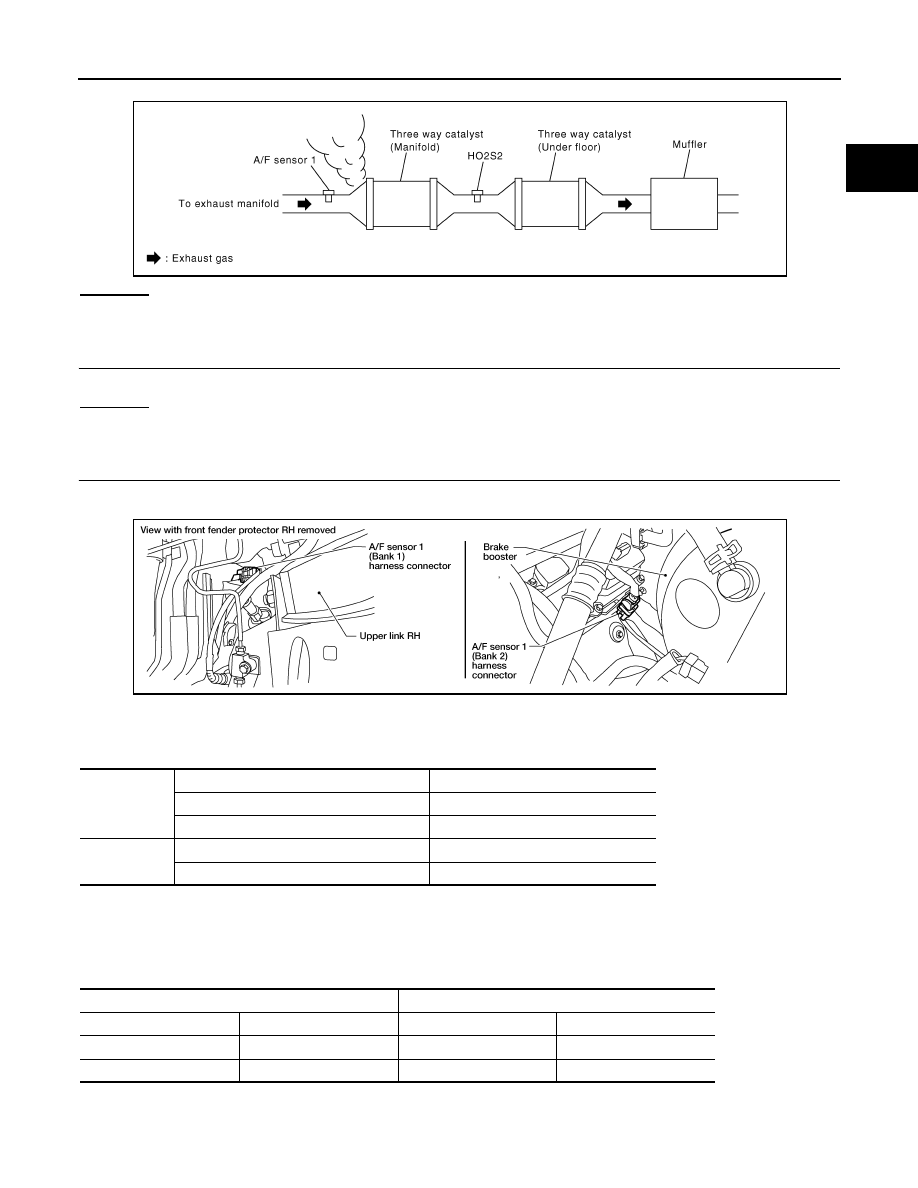

Listen for an exhaust gas leak before three way catalyst (manifold).

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace.

2.

CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace.

3.

CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect corresponding A/F sensor 1 harness connector.

3.

Disconnect ECM harness connector.

4.

Check harness continuity between A/F sensor 1 terminal and ECM terminal as follows.

Refer to Wiring Diagram.

5.

Check harness continuity between the following terminals and ground.

Refer to Wiring Diagram.

6.

Also check harness for short to power.

PBIB1216E

Bank 1

A/F sensor 1 terminal

ECM terminal

1

35

2

56

Bank 2

1

16

2

75

Continuity should exist.

Bank 1

Bank 2

A/F sensor 1 terminal

ECM terminal

A/F sensor 1 terminal

ECM terminal

1

35

1

16

2

56

2

75

Continuity should not exist.

BBIA0544E