Nissan Frontier D40. Manual - part 358

P0117, P0118 ECT SENSOR

EC-123

< COMPONENT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0117, P0118 ECT SENSOR

Component Description

INFOID:0000000005273102

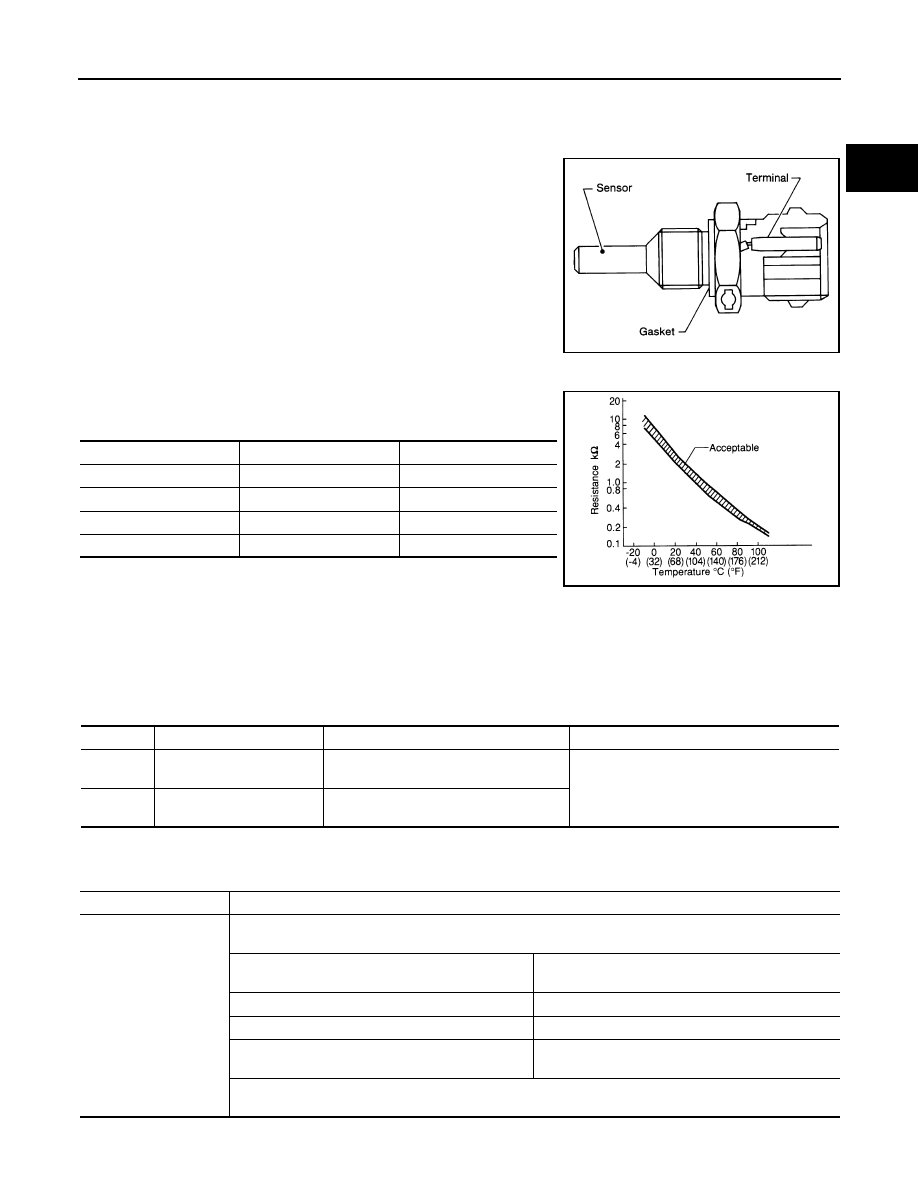

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine coolant

temperature input. The sensor uses a thermistor which is sensitive to

the change in temperature. The electrical resistance of the ther-

mistor decreases as temperature increases.

<Reference data>

*: This data is reference value and is measured between ECM terminal 73 (Engine

coolant temperature sensor) and ground.

CAUTION:

Never use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis Logic

INFOID:0000000005273103

These self-diagnoses have the one trip detection logic.

FAIL-SAFE MODE

When this malfunction is detected, the ECM enters fail-safe mode and the MIL lights up.

SEF594K

Engine coolant [

°

C (

°

F)]

Voltage*

(V)

Resistance

(k

Ω

)

−

10 (14)

4.4

7.0 - 11.4

20 (68)

3.5

2.1 - 2.9

50 (122)

2.2

0.68 - 1.00

90 (194)

0.9

0.236 - 0.260

SEF012P

DTC No.

Trouble Diagnosis Name

DTC Detecting Condition

Possible Cause

P0117

0117

Engine coolant temperature

sensor circuit low input

An excessively low voltage from the sen-

sor is sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted.)

• Engine coolant temperature sensor

P0118

0118

Engine coolant temperature

sensor circuit high input

An excessively high voltage from the sen-

sor is sent to ECM.

Detected items

Engine operating condition in fail-safe mode

Engine coolant temper-

ature sensor circuit

Engine coolant temperature will be determined by ECM based on the following condition.

CONSULT-III displays the engine coolant temperature decided by ECM.

Condition

Engine coolant temperature decided

(CONSULT-III display)

Just as ignition switch is turned ON or START

40

°

C (104

°

F)

Approx. 4 minutes or more after engine starting.

80

°

C (176

°

F)

Except as shown above

40 - 80

°

C (104 - 176

°

F)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling fan operates while

engine is running.