Nissan Titan. Manual - part 356

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-23

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

*2: Target value 37

° 30′ (37.50°)

*3: Target value 33

° 58′ (33.97°)

*4: Target value 37

° 56′ (37.93°)

*5: Target value 34

° 01′ (34.02°)

*6: Some vehicles may be equipped with straight (non-adjustable) lower link bolts and washers. In order to adjust camber and caster on

these vehicles, first replace the lower link bolts and washers with adjustable (cam) bolts and washers.

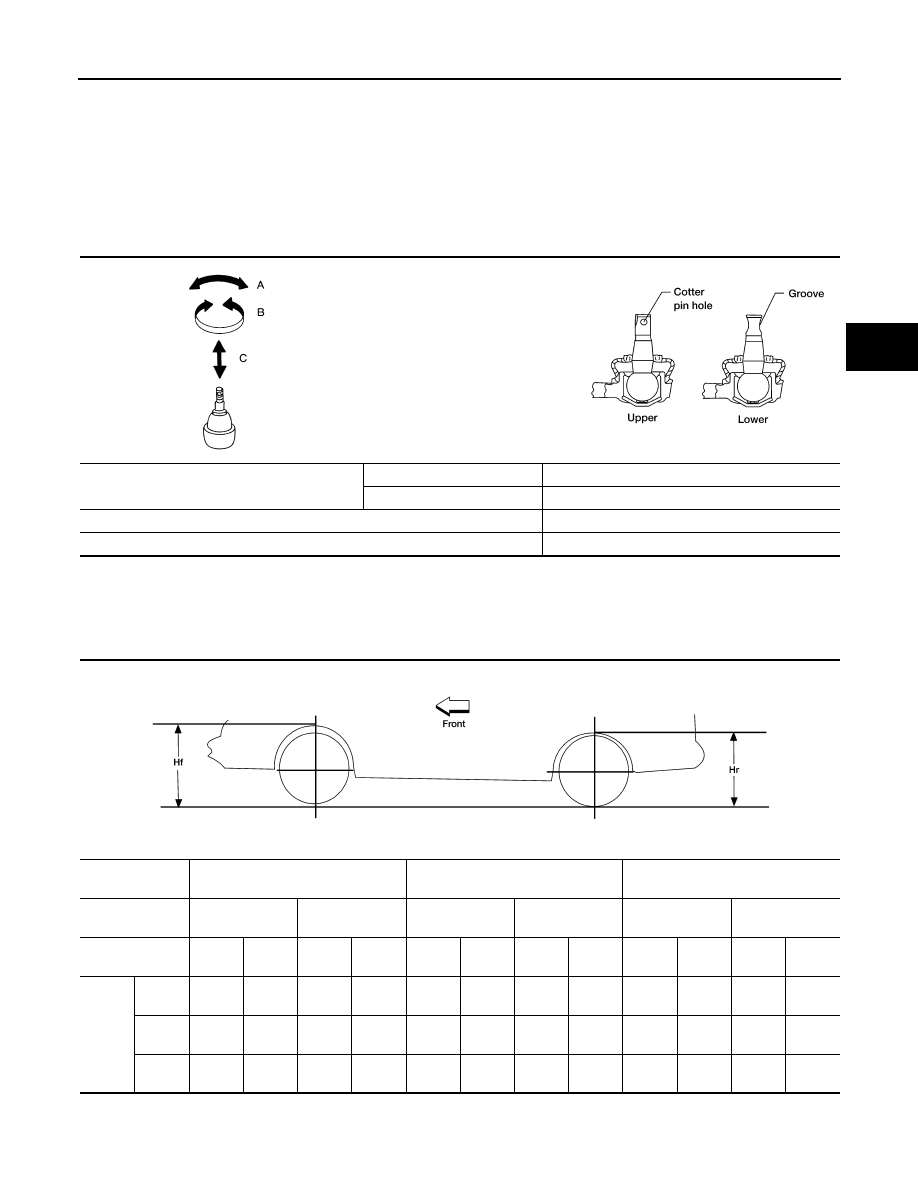

Ball Joint

INFOID:0000000009885612

*1 Measure at cotter pin hole

*2 Measure at groove

Wheelarch Height (Unladen*1)

INFOID:0000000009885613

Unit: mm (in)

Swinging force (A)

Upper ball joint

8.1 – 103.2 N (0.8 – 10.5 kg-f, 1.8 – 23.2 lb-f) *1

Lower ball joint

11.4 – 145.5 N (1.1 – 14.8 kg-f, 2.5 – 32.7 lb-f) *2

Turning torque (B)

0.5 – 6.4 N·m (0.05 – 0.65 kg-m, 4 – 57 in-lb)

Vertical end play (C)

0 mm (0 in)

SFA858A

WEIA0076E

Drive

type

2WD

4WD*2

4WD*3

Wheel

base

Short

Long

Short

Long

Short

Long

Body

King

Cab

Crew

Cab

King

Cab

Crew

Cab

King

Cab

Crew

Cab

King

Cab

Crew

Cab

King

Cab

Crew

Cab

King

Cab

Crew

Cab

Front

wheel

arch

height

(Hf)

P265/

70R18

912

(35.91)

914

(35.98)

912

(35.91)

914

(35.98)

949

(37.36)

951

(37.44)

949

(37.36)

951

(37.44)

949

(37.36)

951

(37.44)

949

(37.36)

951

(37.44)

P275/

70R18

922

(36.30)

925

(36.42)

922

(36.30)

925

(36.42)

960

(37.80)

962

(37.87)

959

(37.76)

962

(37.87)

960

(37.80)

962

(37.87)

959

(37.76)

962

(37.87)

P275/

60R20

917

(36.10)

919

(36.18)

917

(36.10)

920

(36.22)

955

(37.60)

957

(37.68)

954

(37.56)

957

(37.68)

955

(37.60)

957

(37.68)

954

(37.56)

957

(37.68)

LEIA0085E