Nissan Titan. Manual - part 355

KNUCKLE

FSU-19

< REMOVAL AND INSTALLATION >

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

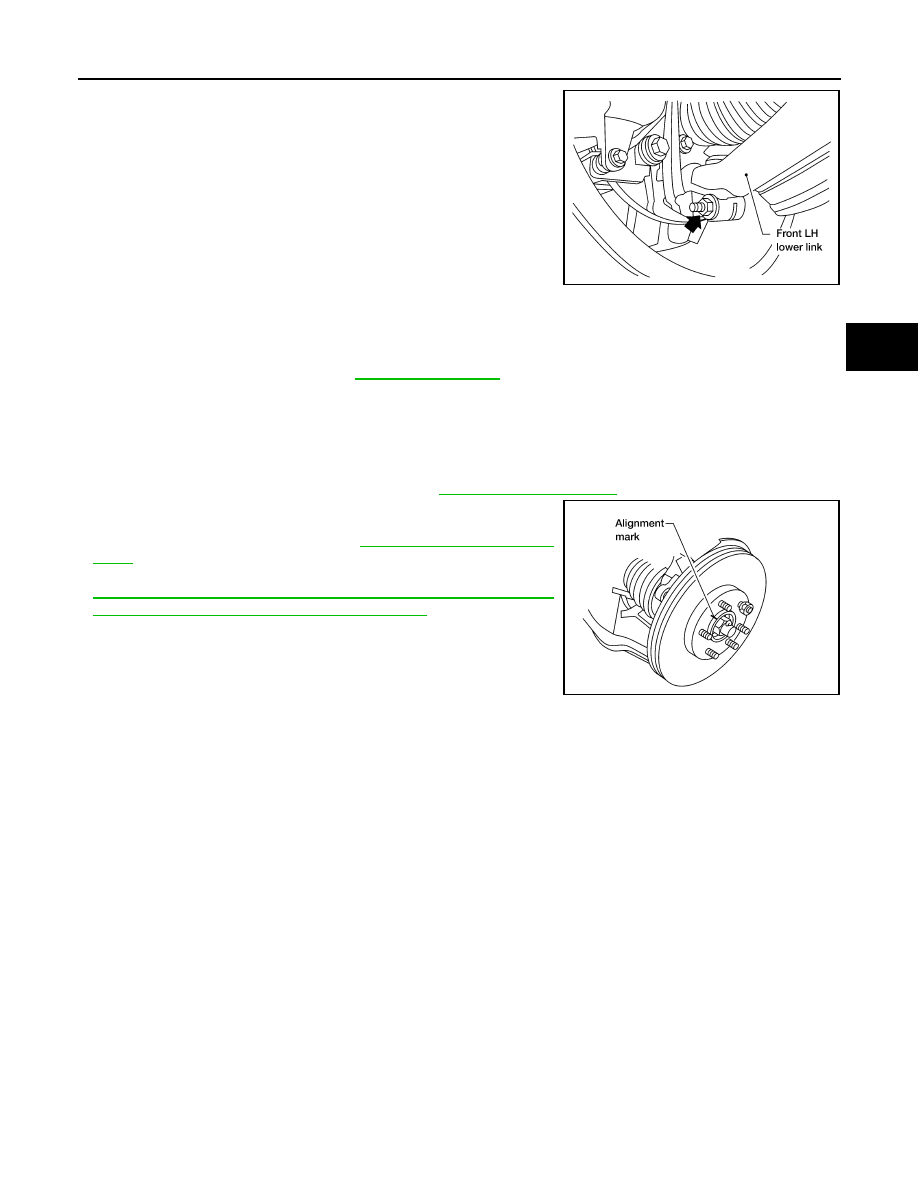

8. Remove the pinch bolt and nut from the steering knuckle using

power tool. Separate the lower link ball joint from the steering

knuckle.

9. Remove the steering knuckle from the vehicle.

INSPECTION AFTER REMOVAL

• Check for deformity, cracks and damage on each part, replace if necessary.

• Perform ball joint inspection. Refer to

.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse the lower link ball joint nut.

• Do not reuse the upper link ball joint cotter pin.

• Tighten all nuts and bolts to specification.Refer to

• When installing disc rotor on wheel hub and bearing assembly,

align the marks.

• Check the wheel alignment. Refer to

.

• Adjust the neutral position of the steering angle sensor. Refer to

BRC-8, "ADJUSTMENT OF STEERING ANGLE SENSOR NEU-

TRAL POSITION : Special Repair Requirement"

LEIA0097E

WDIA0044E