Nissan Titan. Manual - part 257

P0455 EVAP CONTROL SYSTEM

EC-329

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

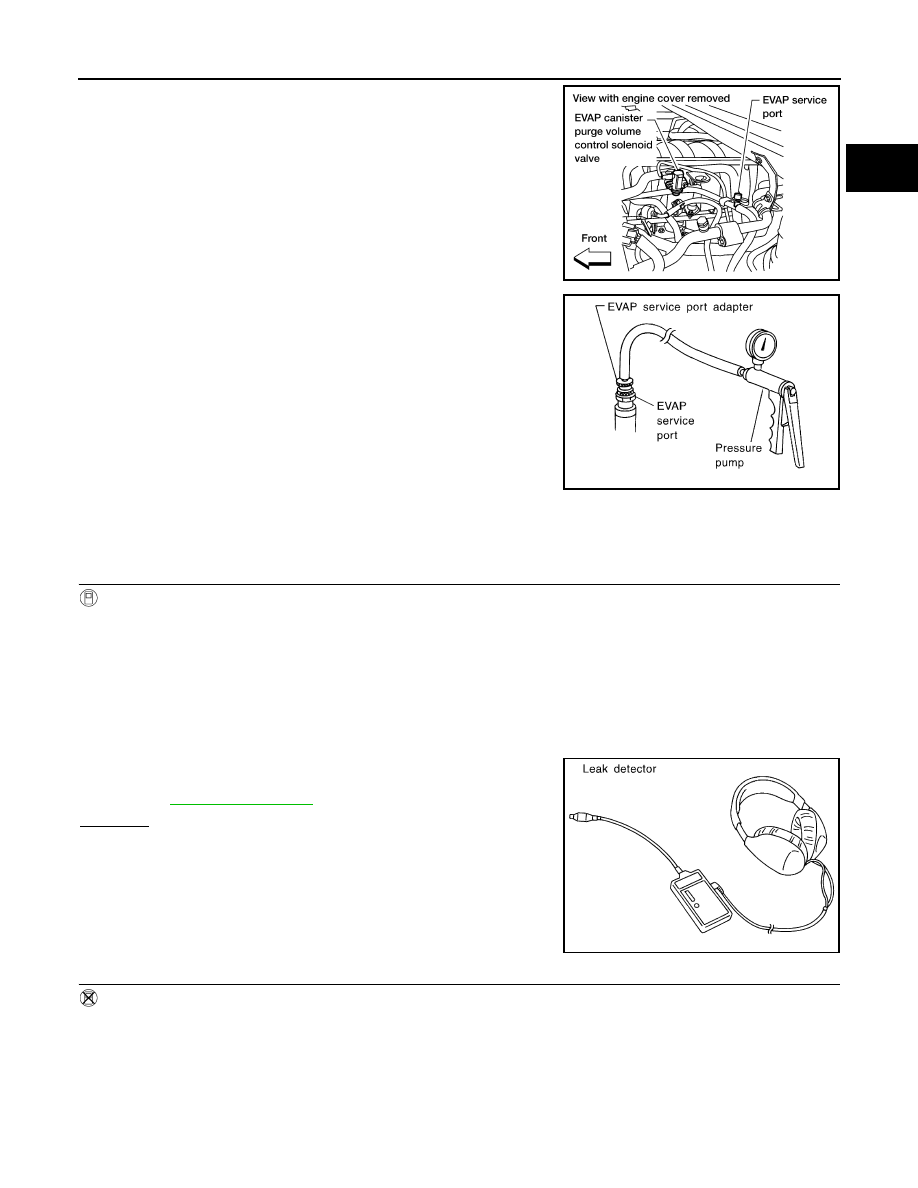

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port securely.

NOTE:

Improper installation of the EVAP service port adapter to the

EVAP service port may cause leaking.

With CONSULT>>GO TO 10.

Without CONSULT>>GO TO 11.

10.

CHECK FOR EVAP LEAK

With CONSULT

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT.

3. Touch “START” and apply pressure into the EVAP line until the pressure indicator reaches the middle of

the bar graph.

CAUTION:

• Do not use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm

2

, 0.6 psi) of pressure in the system.

4. Using EVAP leak detector, locate the EVAP leak. For the leak

detector, refer to the instruction manual for more details.

.

OK or NG

OK

>> GO TO 12.

NG

>> Repair or replace.

11.

CHECK FOR EVAP LEAK

Without CONSULT

1. Turn ignition switch OFF.

BBIA0366E

SEF916U

SEF200U