Nissan Titan. Manual - part 255

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-321

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

Component Description

INFOID:0000000009886732

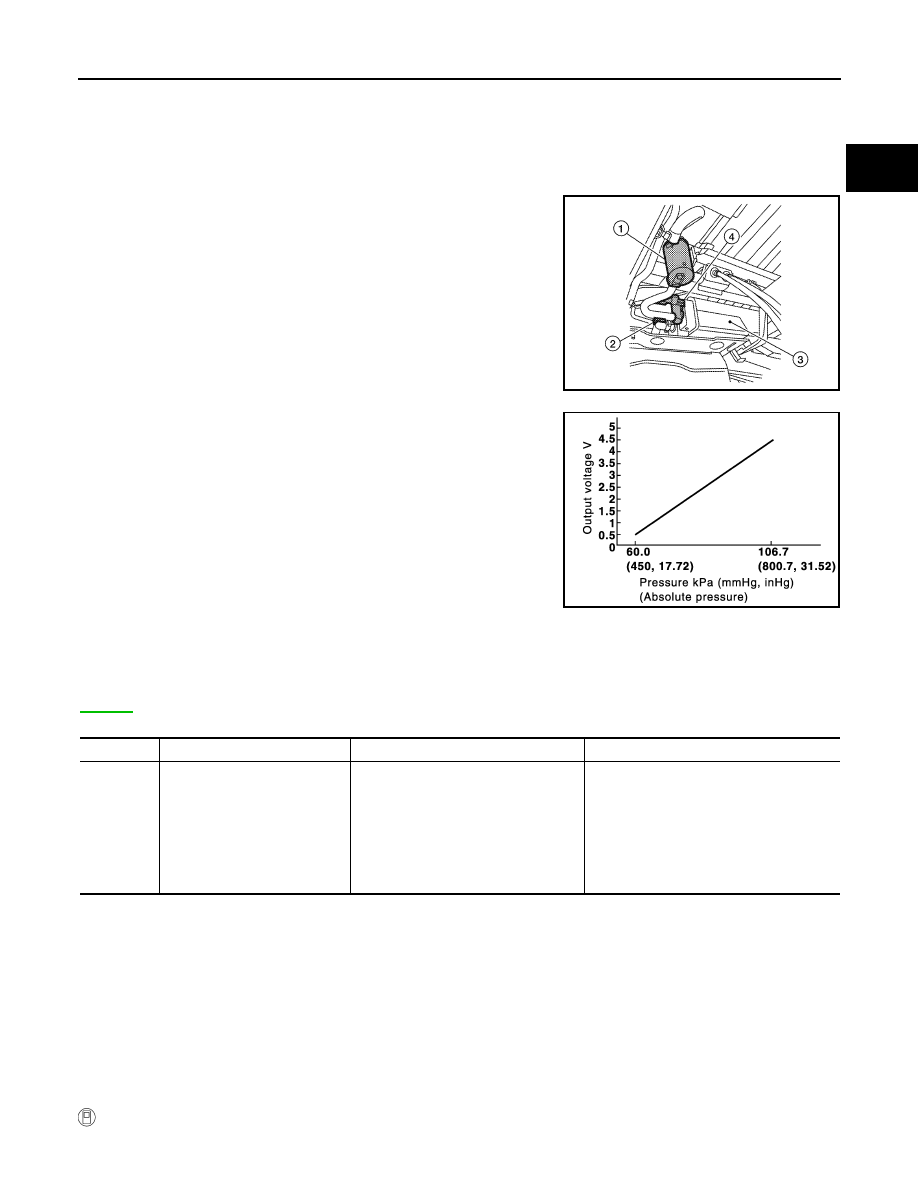

The EVAP control system pressure sensor (2) detects pressure in the purge line. The sensor output voltage to

the ECM increases as pressure increases.

On Board Diagnosis Logic

INFOID:0000000009886733

NOTE:

If DTC P0451 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to

.

DTC Confirmation Procedure

INFOID:0000000009886734

NOTE:

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next step.

1. Turn ignition swich OFF and wait at least 10 seconds.

2. Turn ignition swich ON.

3. Turn ignition swich OFF and wait at least 10 seconds.

TESTING CONDITION:

Always perform test at a temperature of 5

°C (41°F) or more.

With CONSULT

1

: Drain filter

3

: EVAP canister

4

: EVAP canister vent control value

ALBIA0401ZZ

PBIB1207E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0453

0453

EVAP control system pressure

sensor high input

An excessively high voltage from the

sensor is sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted.)

• EVAP control system pressure sensor

• EVAP canister vent control valve

• EVAP canister

• Drain filter

• Rubber hose from EVAP canister vent

control valve to drain filter