Nissan Titan A60. Manual - part 969

TM-264

< UNIT DISASSEMBLY AND ASSEMBLY >

ASSEMBLY

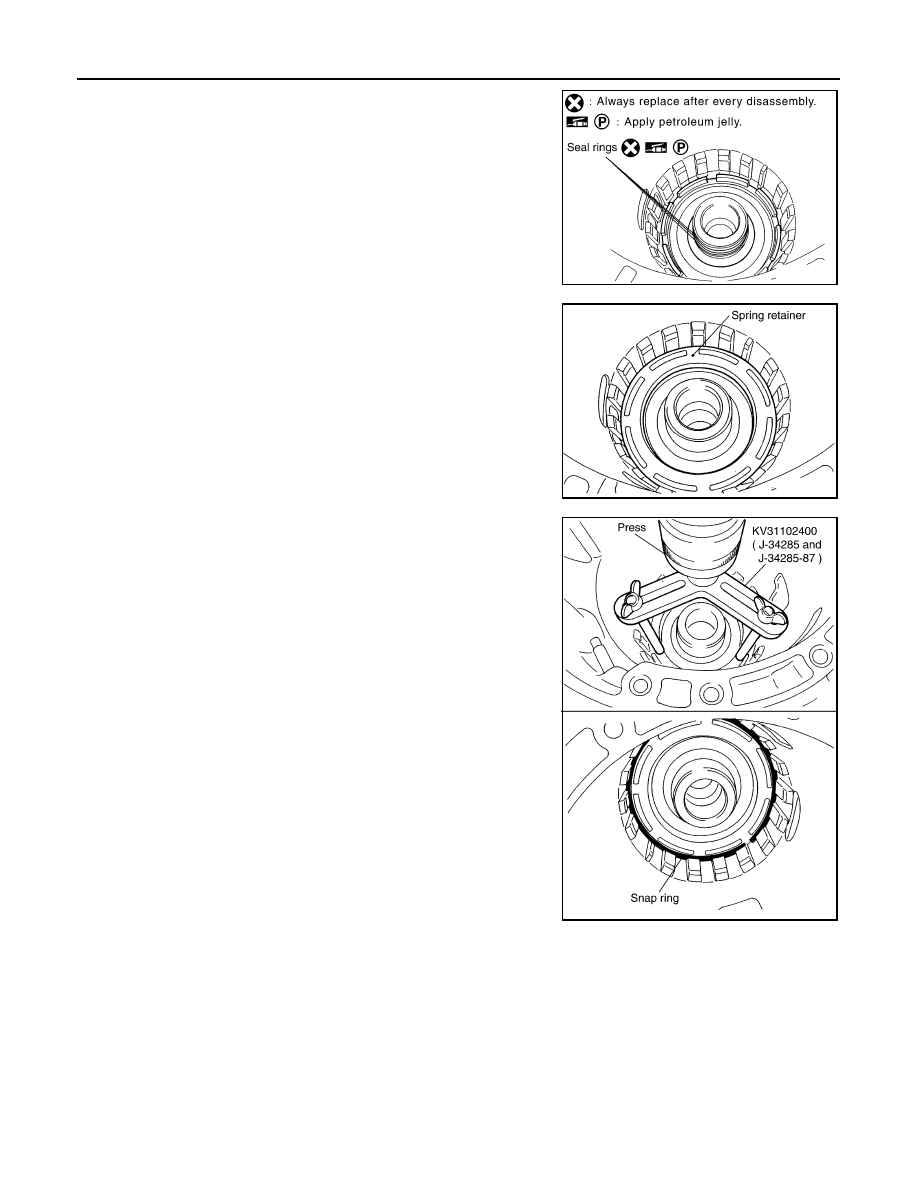

15. Install seal rings to drum support.

CAUTION:

• Do not reuse seal rings.

• Apply petroleum jelly to seal rings.

16. Install spring retainer and return spring in transmission case.

17. Install snap ring in transmission case while compressing return

spring using Tool.

CAUTION:

Securely assemble them using a flat-bladed screwdriver so

that snap ring tension is slightly weak.

18. Install revers brake drive plates driven plates and dish plates in transmission case.

CAUTION:

SCIA3333E

SCIA2324E

Tool number

: KV31102400 (J-34285 and J-34285-87)

SCIA5877E