Nissan Titan A60. Manual - part 946

TM-172

< PERIODIC MAINTENANCE >

A/T FLUID COOLER

A/T FLUID COOLER

A/T Fluid Cooler Cleaning

INFOID:0000000006159438

Whenever an A/T is repaired, overhauled, or replaced, the A/T fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can become trapped in the A/T fluid cooler. This debris can con-

taminate the newly serviced A/T or, in severe cases, can block or restrict the flow of A/T fluid. In either case,

malfunction of the newly serviced A/T may result.

Debris, if present, may build up as A/T fluid enters the cooler inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

A/T FLUID COOLER CLEANING PROCEDURE

1. Position a drain pan under the A/T inlet and outlet fluid cooler tube to cooler hose connection.

2. Put a different color matching mark on each cooler tube to cooler hose connection to aid in assembly.

CAUTION:

Use paint to make the matching mark. Do not damage the tubes or hose.

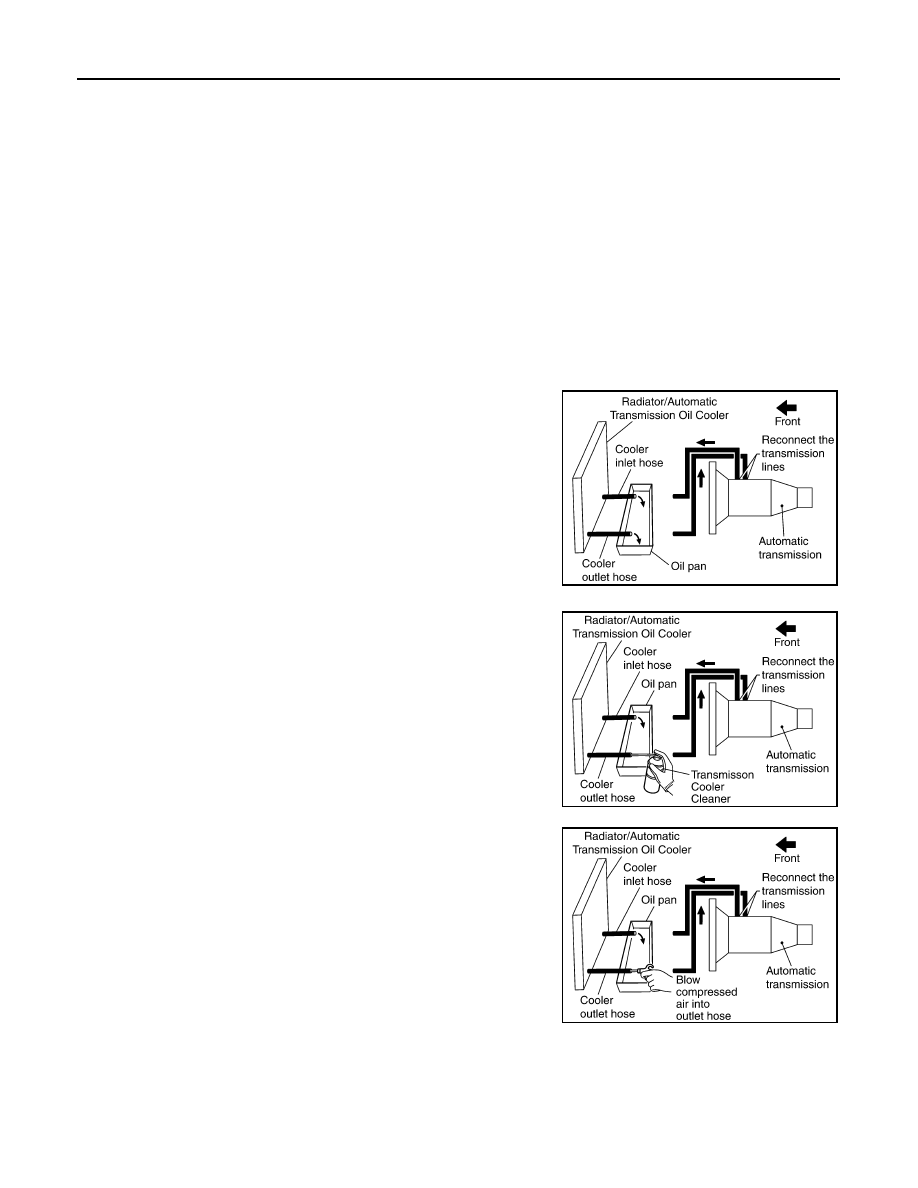

3. Disconnect the fluid cooler inlet and outlet rubber hoses from the

steel cooler tubes.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

4. Drain any A/T fluid from the cooler hose.

5. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the

Transmission Cooler Cleaner.

• Spray cooler cleaner only with adequate ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

6. Hold the hose and can as high as possible and spray Transmis-

sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until fluid flows out of the cooler inlet hose for 5 seconds.

7. Insert the tip of an air gun into the end of the cooler outlet hose.

8. Wrap a shop rag around the tip of the air gun and the cooler out-

let hose.

9. Blow compressed air regulated to 5 - 9 kg/cm

2

(70 - 130 psi) through the cooler outlet hose for 10 seconds

to force out any remaining fluid.

10. Repeat steps 5 through 9 three additional times.

11. Position an oil pan under the banjo bolts that connect the fluid cooler tubes to the A/T.

12. Remove the banjo bolts.

SCIA3830E

SCIA3831E

SCIA3832E