Nissan Titan A60. Manual - part 451

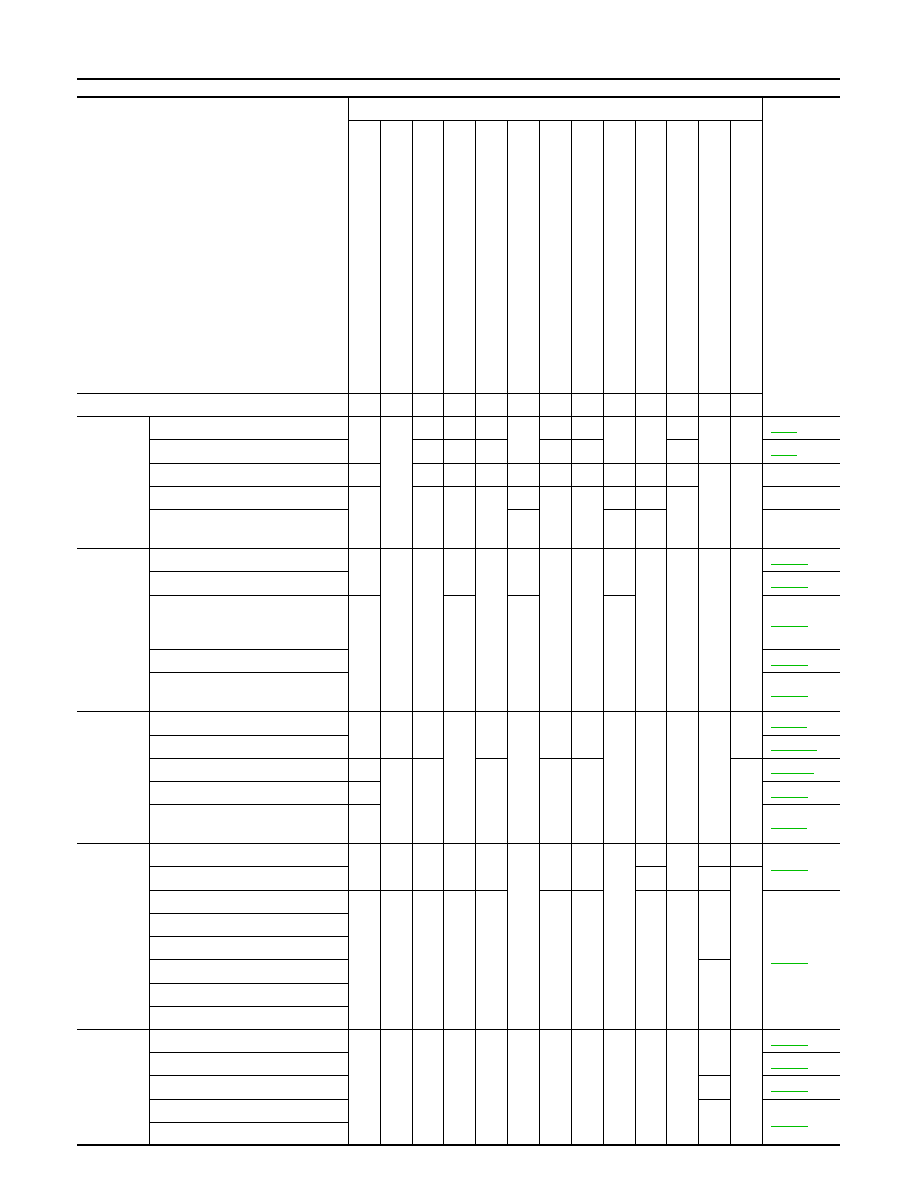

EC-470

< SYMPTOM DIAGNOSIS >

[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

SYMPTOM

Reference

page

HARD/NO ST

AR

T/REST

AR

T (EXCP

.

HA)

E

N

GI

N

E

ST

AL

L

HESIT

A

TION/S

U

R

GING/F

LA

T SP

OT

SP

ARK KNOCK/DE

T

O

NA

TION

LACK OF POWE

R/POOR

ACCELERA

TIO

N

HIGH IDL

E/L

OW

IDL

E

ROUG

H IDLE/HU

NTING

IDL

ING VIBRA

T

ION

SLO

W

/NO RETURN T

O

IDLE

OVERHEA

T

S/W

A

TE

R

TEMPERA

T

URE

HIGH

EXCES

SIVE F

U

EL CONSUMP

T

ION

EXCES

SIVE OI

L CONSUMP

T

IO

N

BA

TTE

R

Y

DEAD (UN

D

E

R

CH

A

R

GE)

Warranty symptom code

AA

AB

AC

AD

AE

AF

AG AH

AJ

AK

AL

AM HA

Fuel

Fuel tank

5

5

Fuel piping

5

5

5

5

5

5

Vapor lock

—

Valve deposit

5

5

5

5

5

5

5

—

Poor fuel (Heavy weight gasoline,

Low octane)

—

Air

Air duct

5

5

5

5

5

5

Air cleaner

Air leakage from air duct

(Mass air flow sensor — electric

throttle control actuator)

5

5

5

5

Electric throttle control actuator

Air leakage from intake manifold/

Collector/Gasket

Cranking

Battery

1

1

1

1

1

1

1

1

Generator circuit

Starter circuit

3

Signal plate

6

Park/neutral position (PNP) sig-

nal

4

Engine

Cylinder head

5

5

5

5

5

5

5

5

Cylinder head gasket

4

3

Cylinder block

6

6

6

6

6

6

6

6

4

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mecha-

nism

Timing chain

5

5

5

5

5

5

5

5

Camshaft

Intake valve timing control

Intake valve

3

Exhaust valve