Nissan Titan A60. Manual - part 298

PROPELLER SHAFT

DLN-131

< REMOVAL AND INSTALLATION >

[PROPELLER SHAFT: 2F1310]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

REMOVAL AND INSTALLATION

PROPELLER SHAFT

On-Vehicle Service

INFOID:0000000006179517

APPEARANCE AND NOISE INSPECTION

• Check the propeller shaft tube surface for dents or cracks. If damaged, replace the propeller shaft assembly.

• Check the bearings for noise and damage. Repair or replace the bearings as necessary.

PROPELLER SHAFT VIBRATION

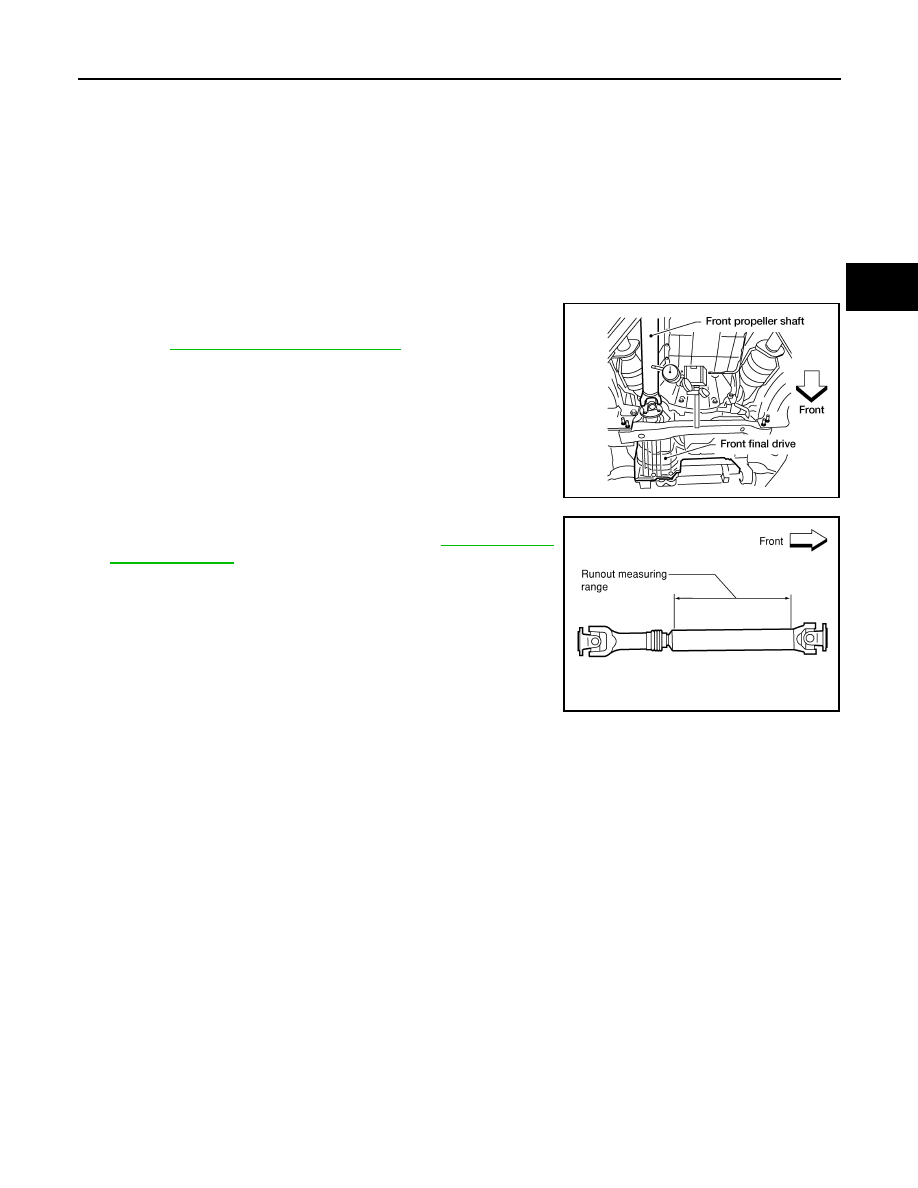

If a vibration is present at high speed, inspect the propeller shaft runout first.

1. Measure the runout of the propeller shaft tube at several points

by rotating the final drive companion flange with your hands.

DLN-136, "General Specification"

.

2. If the runout exceeds specifications, disconnect the propeller

shaft at the final drive companion flange; then rotate the com-

panion flange 90

°, 180° and 270° and reconnect the propeller

shaft.

3. Check the runout again. If the runout still exceeds specifications,

replace the propeller shaft assembly. Refer to

.

4. After installation, check for vibration by driving the vehicle.

LDIA0160E

LDIA0118E