Nissan Titan A60. Manual - part 192

BODY CONSTRUCTION

BRM-27

< UNIT REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

L

M

A

B

BRM

N

O

P

4. Disconnect the fuel filler neck from the bed side outer.

5. Remove the rear bumper assembly.

6. Remove the pick-up bed assembly.

Installation

Installation is in the reverse order of removal.

• Shim as necessary for proper fit and finish.

Foam Repair

INFOID:0000000006158471

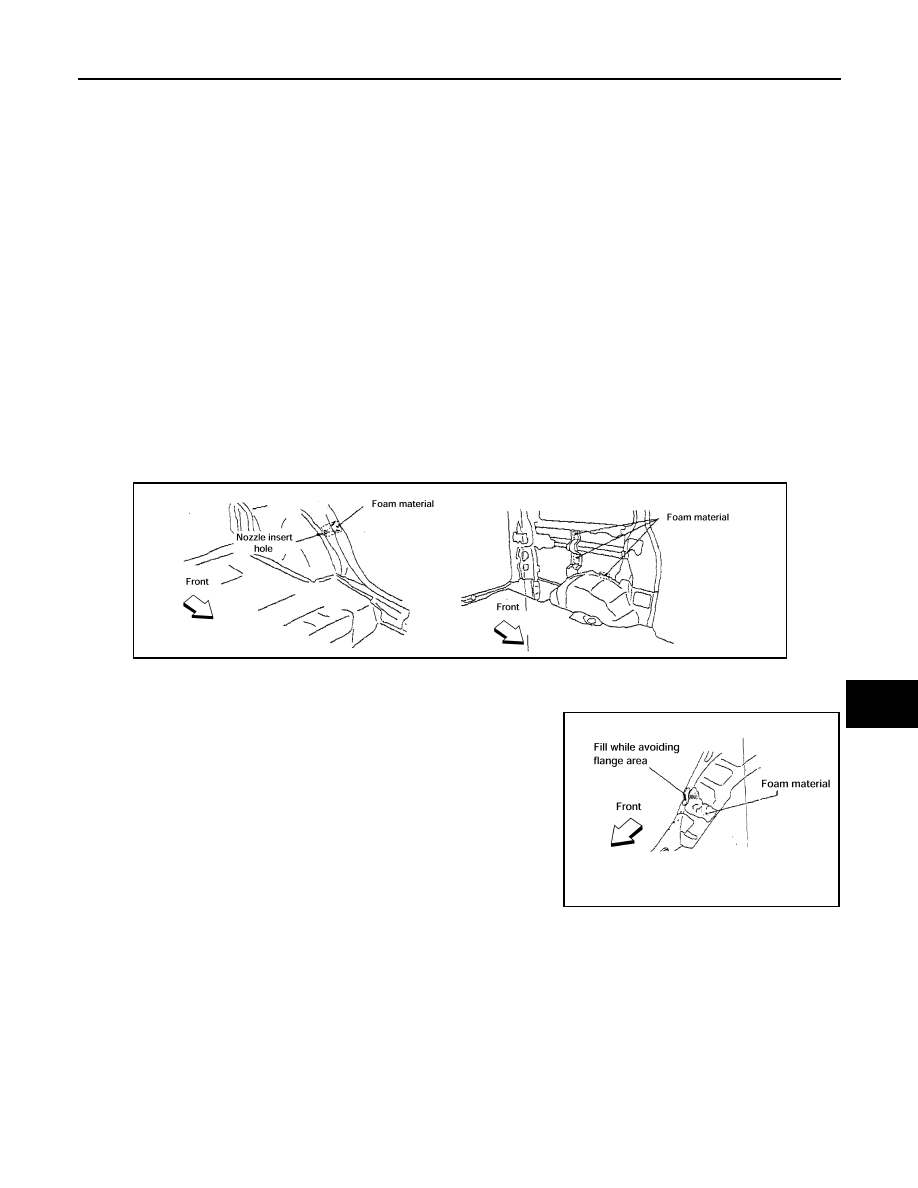

During factory body assembly, foam insulators are installed in certain body panels and locations around the

vehicle. Use the following procedure(s) to replace any factory-installed foam insulators.

URETHANE FOAM APPLICATIONS

Use commercially available spray foam for sealant (foam material) repair of material used on vehicle. Read

instructions on product for fill procedures.

FILL PROCEDURES

1. Fill procedures after installation of service part.

-

Remove foam material remaining on vehicle side.

-

Clean area in which foam was removed.

-

Install service part.

-

Insert nozzle into hole near fill area and fill foam material or fill in enough to close gap with the service

part.

2. Fill procedures before installation of service part.

-

Remove foam material remaining on vehicle side.

-

Clean area in which foam was removed.

-

Fill foam material on wheelhouse outer side.

NOTE:

Fill in enough to close gap with service part while avoiding flange

area.

-

Install service part.

NOTE:

Refer to label for information on working times.

LIIA1081E

LIIA1082E