Nissan Titan A60. Manual - part 190

CORROSION PROTECTION

BRM-19

< UNIT REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

L

M

A

B

BRM

N

O

P

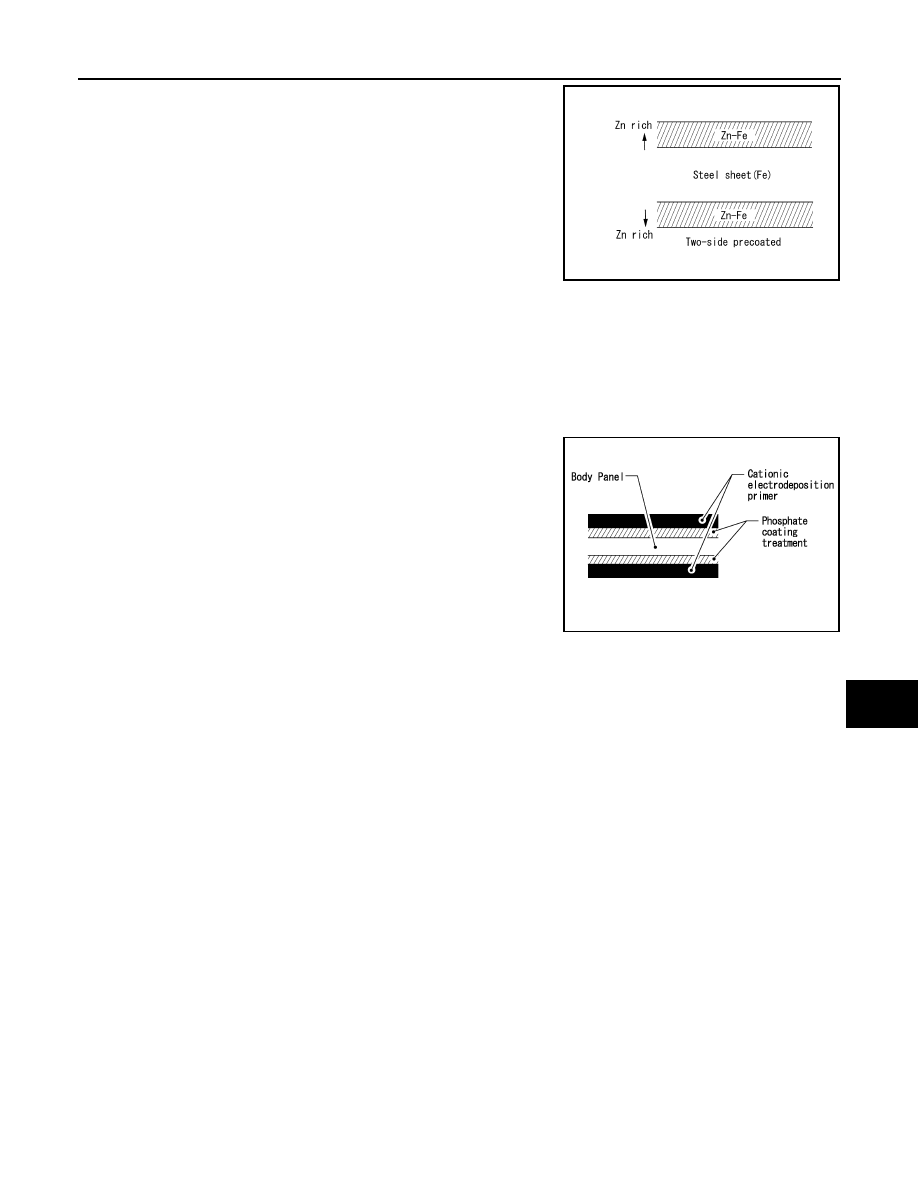

To improve repairability and corrosion resistance, a new type of anti-

corrosive precoated steel sheet has been adopted replacing conven-

tional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron

alloy, which provides excellent and long term corrosion resistance

with cationic electrode position primer.

Nissan Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that

GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive perfor-

mance built into the vehicle at the factory.

PHOSPHATE COATING TREATMENT AND CATIONIC ELECTRODEPOSITION PRIMER

A phosphate coating treatment and a cationic electrode position primer, which provide excellent corrosion pro-

tection, are employed on all body components.

CAUTION:

Confine paint removal during welding operations to an absolute

minimum.

Nissan Genuine Service Parts are also treated in the same manner. Therefore, it is recommended that GENU-

INE NISSAN PARTS or equivalent be used for panel replacement to maintain anti-corrosive performance built

into the vehicle at the factory.

ANTI-CORROSIVE WAX

To improve corrosion resistance, anti-corrosive wax is applied inside the body sill and inside other closed sec-

tions. Accordingly, when replacing these parts, be sure to apply anti-corrosive wax to the appropriate areas of

PIIA0093E

PIIA0095E