Nissan Quest E52. Manual - part 821

REAR CONSOLE ASSEMBLY

IP-33

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

K

L

M

A

B

IP

N

O

P

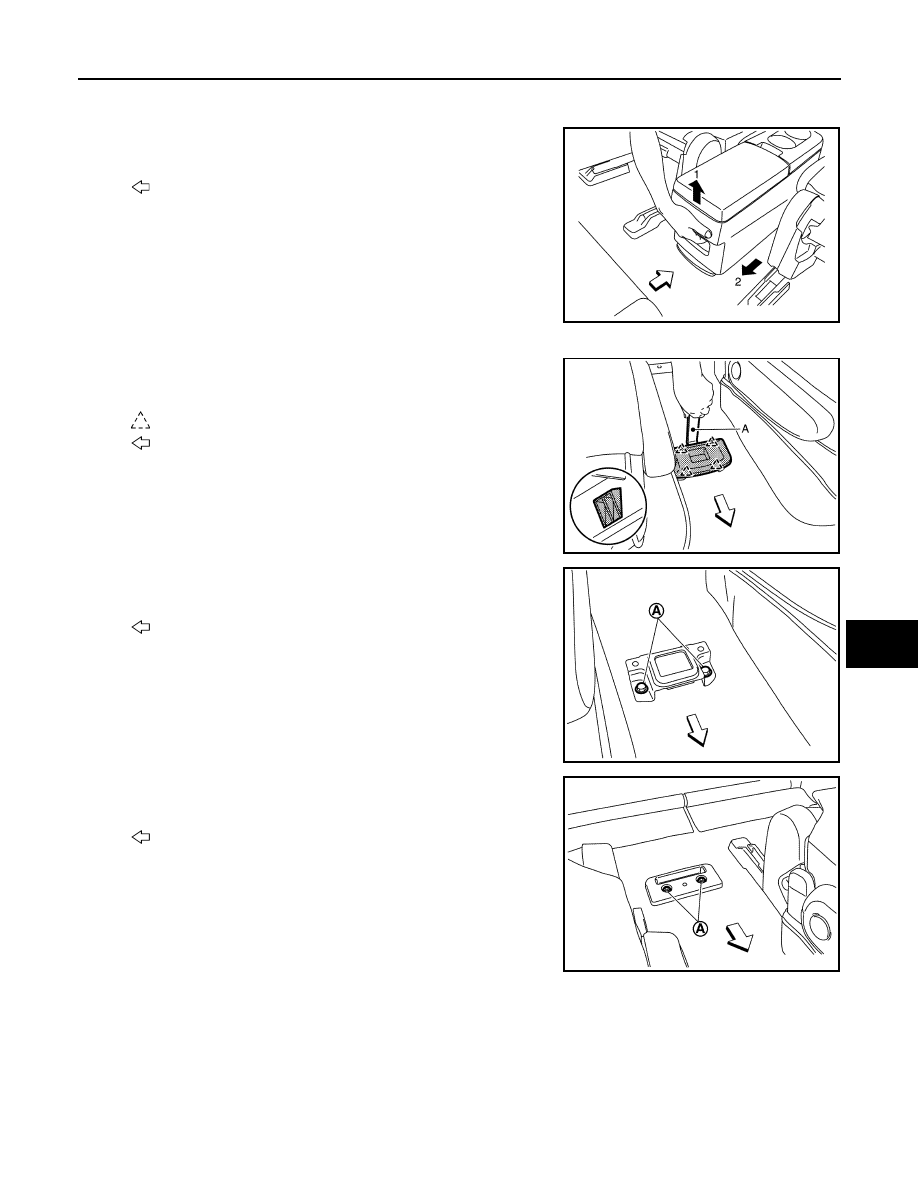

REMOVAL

1.

Remove rear console assembly.

Pull up latch handle of console latch assembly, and then remove

rear console assembly sliding toward vehicle rear.

2.

Remove rear console bases and brackets.

a.

Insert a remover tool (A) between rear console front base and

body floor to disengage the pawls as shown in the figure.

b.

Remove fixing bolts (A), and then remove rear console front

bracket.

c.

Remove fixing bolts (A), and then remove rear console rear

base.

d.

Remove fixing bolts, and then remove rear console rear bracket.

INSTALLATION

Install in the reverse order of removal.

Disassembly and Assembly

INFOID:0000000009650906

Disassembly and Assembly of Rear Console Assembly.

CAUTION:

: Vehicle front

JMJIA6166ZZ

Pawl

: Vehicle front

JMJIA6167ZZ

: Vehicle front

JMJIA6168ZZ

: Vehicle front

JMJIA6169ZZ