Nissan Quest E52. Manual - part 668

BACK DOOR FINISHER

EXT-47

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

L

M

A

B

EXT

N

O

P

BACK DOOR FINISHER

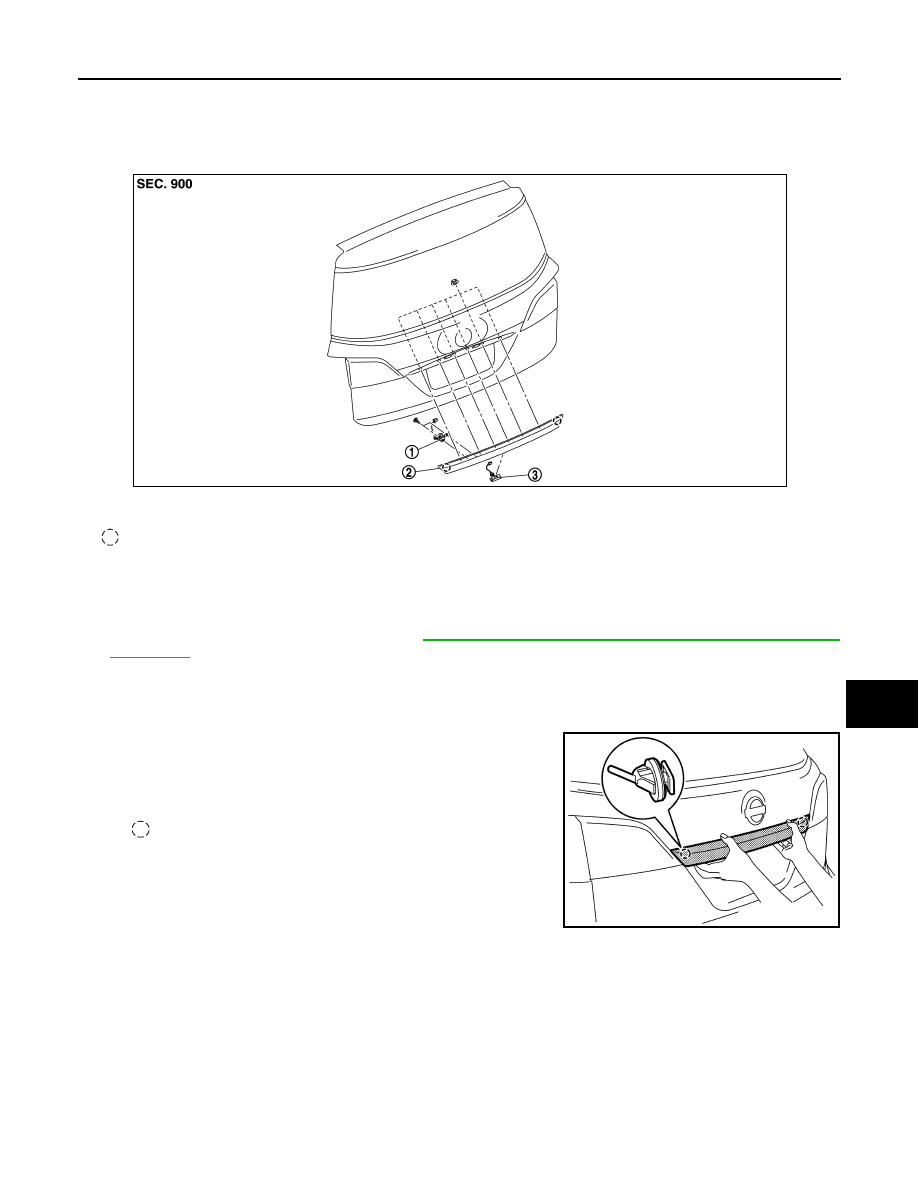

Exploded View

INFOID:0000000009650523

Removal and Installation

INFOID:0000000009650524

REMOVAL

1.

Remove back door lower finisher. Refer to

INT-48, "BACK DOOR LOWER FINISHER : Removal and

.

2.

Remove back door finisher mounting nuts.

3.

Disconnect back door opener request switch and rear view camera harness connectors.

4.

Remove harness grommet.

5.

Pull back door finisher diagonally downward, disengage fixing

clips of back door finisher, and then remove back door finisher.

CAUTION:

Never pull back door finisher strongly.

INSTALLATION

Install in the reverse order of removal.

1.

Rear view camera

2.

Back door finisher

3.

Back door opener request switch

: Clip

JMKIA8278ZZ

: Clip

JMKIA8279ZZ