Nissan Quest E52. Manual - part 651

EXL-208

< SYMPTOM DIAGNOSIS >

[HALOGEN TYPE]

BOTH SIDE FRONT FOG LAMPS ARE NOT TURNED ON

BOTH SIDE FRONT FOG LAMPS ARE NOT TURNED ON

Description

INFOID:0000000009653185

The front fog lamps are not turned ON in any condition.

Diagnosis Procedure

INFOID:0000000009653186

1.

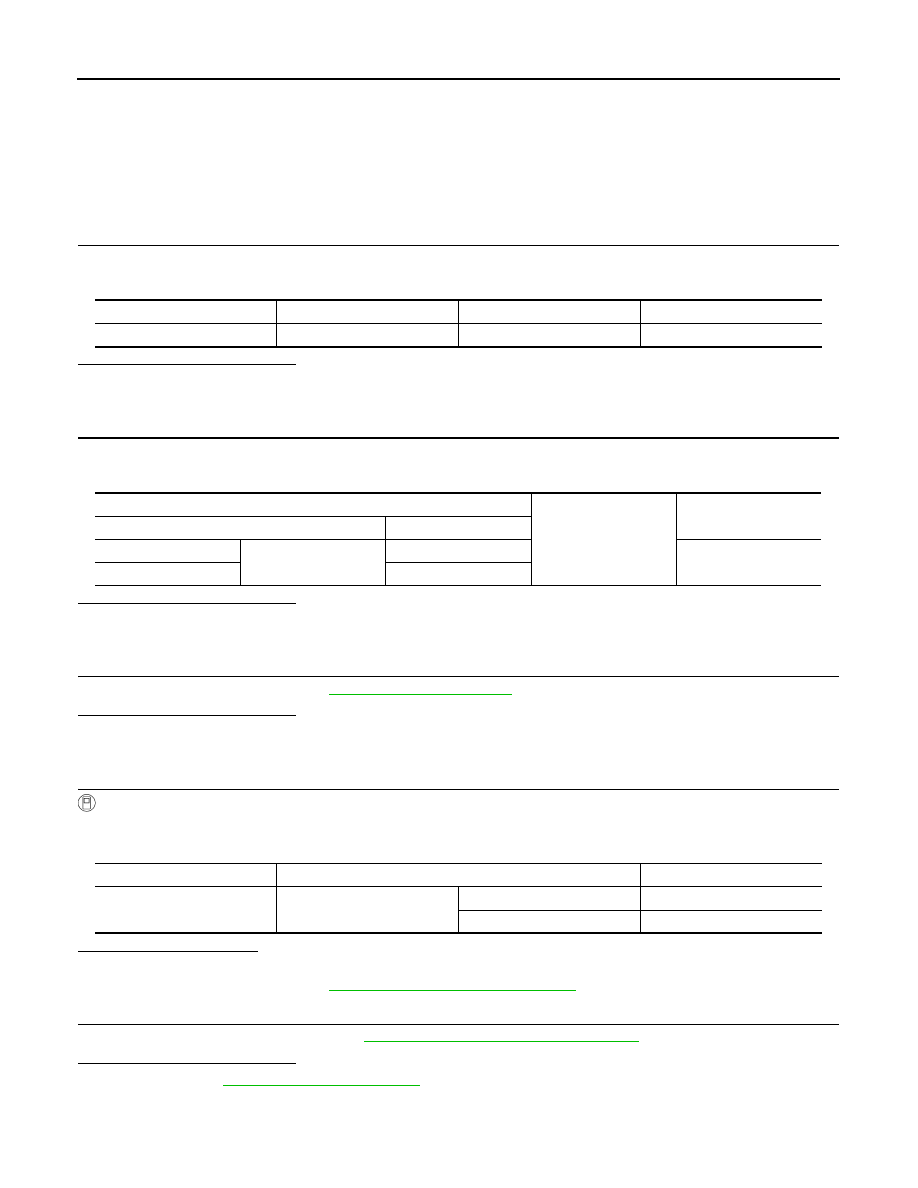

CHECK FRONT FOG LAMP FUSE

1.

Turn ignition switch OFF.

2.

Check that the following fuse is not fusing.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 2.

2.

CHECK FRONT FOG LAMP SHORT CIRCUIT

1.

Disconnect front fog connector and IPDM E/R connector.

2.

Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal?

YES

>> Replace fuse. (Replace IPDM E/R if the fuse is fusing again.)

NO

>> Repair or replace harness. And then replace the fuse.

3.

COMBINATION SWITCH INSPECTION

Check combination switch. Refer to

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace the malfunctioning part.

4.

CHECK FRONT FOG LAMP REQUEST SIGNAL INPUT

CONSULT DATA MONITOR

1.

Select “FR FOG REQ” of IPDM E/R data monitor item.

2.

With operating the front fog lamp switch, check the monitor status.

Is the item status normal?

YES

>> GO TO 5.

NO

>> Replace BCM. Refer to

BCS-98, "Removal and Installation"

5.

FRONT FOG LAMP CIRCUIT INSPECTION

Check the front fog lamp circuit. Refer to

EXL-191, "Component Function Check"

.

Is the inspection result normal?

YES

>> Refer to

GI-42, "Intermittent Incident"

.

NO

>> Repair or replace the malfunctioning part.

Unit

Location

Fuse No.

Capacity

Front fog lamp

IPDM E/R

#58

15 A

IPDM E/R

Ground

Continuity

Connector

Terminal

RH

E345

86

Not existed

LH

87

Monitor item

Condition

Monitor status

FR FOG REQ

Front fog lamp switch

(With lighting switch 2ND)

ON

On

OFF

Off