Nissan Quest E52. Manual - part 576

IGNITION COIL, SPARK PLUG AND ROCKER COVER

EM-53

< REMOVAL AND INSTALLATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

• Engine cover: Refer to

• Air cleaner cases (upper and lower) and air duct assembly: Refer to

.

• Intake manifold collector: Refer to

.

2.

Disconnect PCV hose from rocker cover.

3.

Remove camshaft position sensor (PHASE) (bank 1 and bank

2).

CAUTION:

• Handle carefully to avoid dropping and shocks.

• Never disassemble

• Never allow metal powder to adhere to magnetic part at

sensor tip.

• Never place sensors in a location where they are exposed

to magnetism.

4.

Remove PCV valve and O-ring from rocker cover, if necessary.

5.

Remove oil filler cap from rocker cover, if necessary.

6.

Remove ignition coil.

CAUTION:

Never shock ignition coil.

7.

Remove harness clips on the rocker cover.

8.

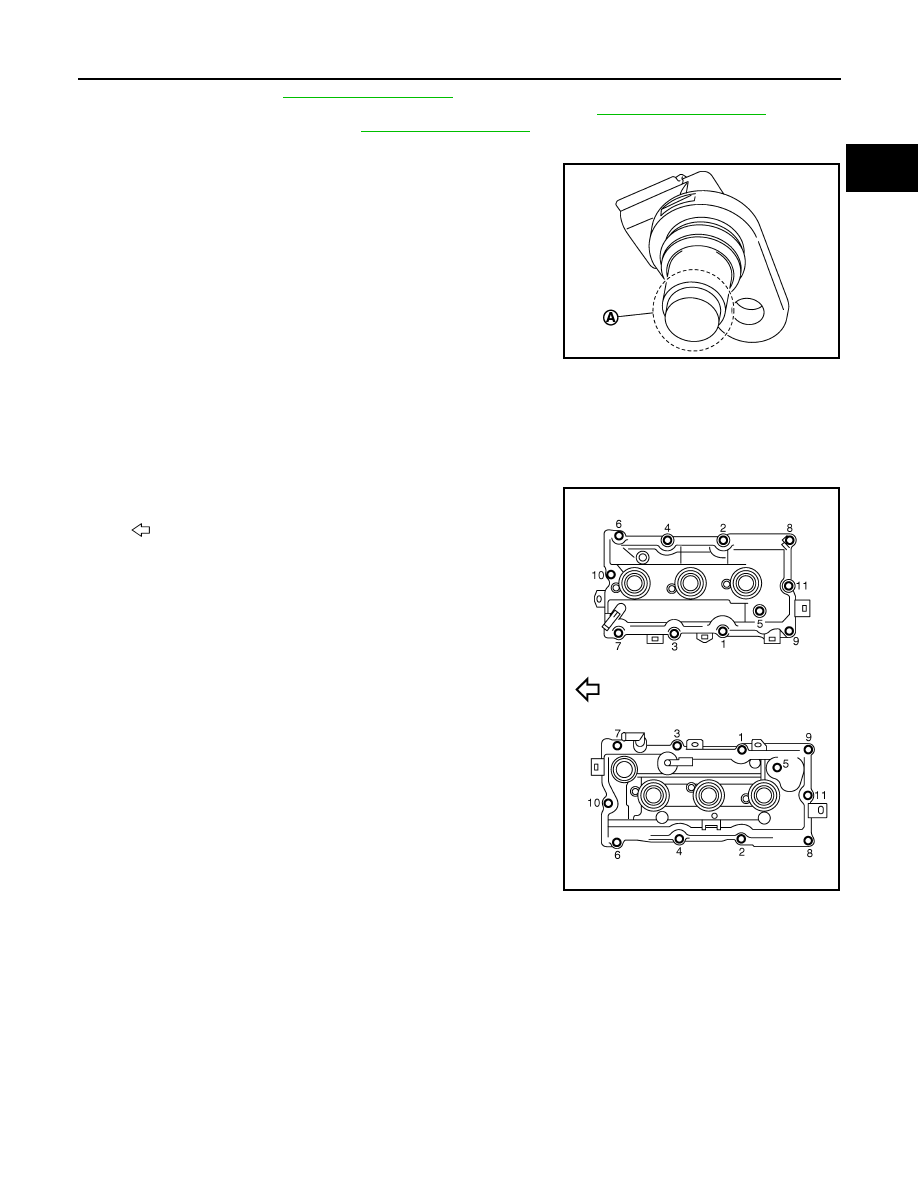

Loosen bolts in the reverse order shown in the figure.

9.

Remove rocker cover gasket from rocker cover.

10. Use scraper to remove all traces of liquid gasket from cylinder head and camshaft bracket (No. 1).

CAUTION:

Never scratch or damage the mating surface when cleaning off old liquid gasket.

INSTALLATION

CAUTION:

Do not reuse O-rings.

A

: Keep off any magnetic materials

: Engine front

JPBIA0454ZZ

JPBIA1634ZZ