Nissan Quest E52. Manual - part 460

EC-50

< SYSTEM DESCRIPTION >

[VQ35DE]

SYSTEM

The evaporative emission system is used to reduce hydrocarbons emitted into the atmosphere from the fuel

system. This reduction of hydrocarbons is accomplished by activated charcoals in the EVAP canister.

The fuel vapor in the sealed fuel tank is led into the EVAP canister which contains activated carbon and the

vapor is stored there when the engine is not operating or when refueling to the fuel tank.

The vapor in the EVAP canister is purged by the air through the purge line to the intake manifold when the

engine is operating. EVAP canister purge volume control solenoid valve is controlled by ECM. When the

engine operates, the flow rate of vapor controlled by EVAP canister purge volume control solenoid valve is

proportionally regulated as the air flow increases.

EVAP canister purge volume control solenoid valve also shuts off the vapor purge line during decelerating and

idling.

INTAKE VALVE TIMING CONTROL

INTAKE VALVE TIMING CONTROL : System Description

INFOID:0000000009650964

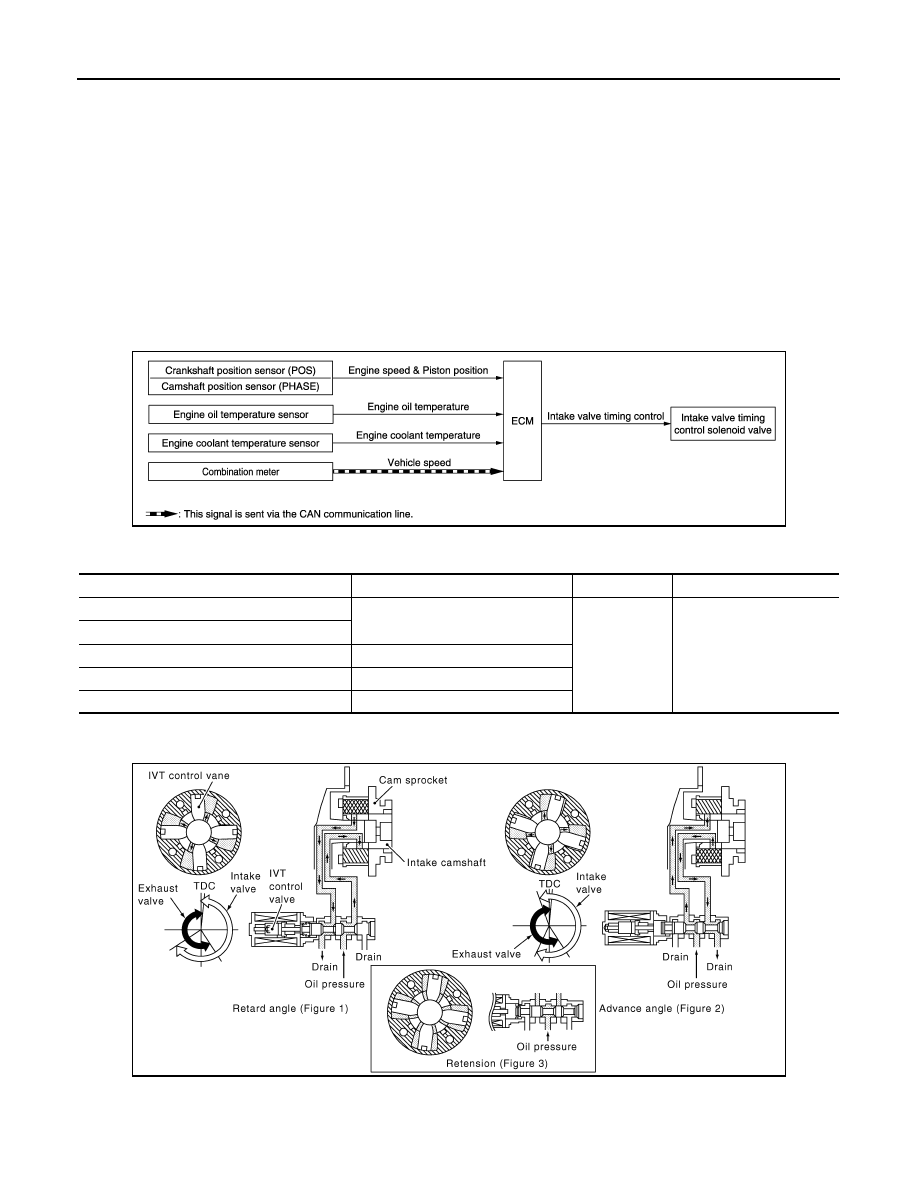

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM via the CAN communication line

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases continuously with the fixed operating angle of the intake

valve.

The ECM receives signals such as crankshaft position, camshaft position, engine speed, and engine coolant

temperature. Then, the ECM sends ON/OFF pulse duty signals to the intake valve timing (IVT) control sole-

JMBIA1830GB

Sensor

Input signal to ECM

ECM function

Actuator

Crankshaft position sensor (POS)

Engine speed and piston position

Intake valve

timing control

Intake valve timing control

solenoid valve

Camshaft position sensor (PHASE)

Engine oil temperature sensor

Engine oil temperature

Engine coolant temperature sensor

Engine coolant temperature

Combination meter

Vehicle speed*

JMBIA0060GB