Nissan Quest E52. Manual - part 215

BR-4

< PRECAUTION >

PRECAUTIONS

• Always confirm the specified tightening torque when installing the brake pipes.

• After pressing the brake pedal more deeply or harder than normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

• Always clean with new brake fluid when cleaning the master cylinder, brake caliper and other components.

• Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

• Always loosen the brake tube flare nut with a flare nut wrench.

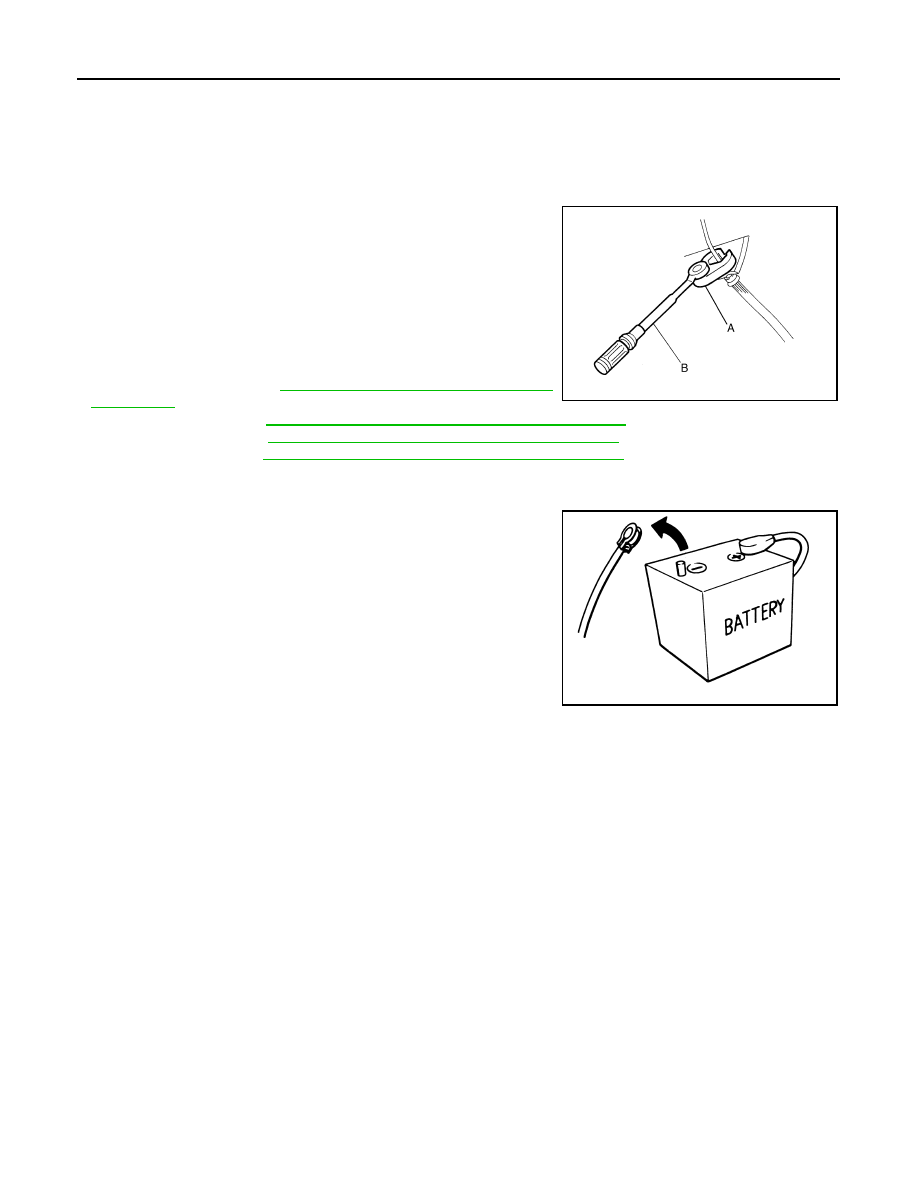

• Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

• Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) harness connector or the battery negative

terminal before performing the work.

• Check that no brake fluid leakage is present after replacing the

parts.

• Burnish the brake contact surfaces after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low

mileage.

- Front brake pad: Refer to

BR-14, "BRAKE PAD : Inspection and

.

- Front disc rotor: Refer to

BR-14, "DISC ROTOR : Inspection and Adjustment"

.

- Rear brake pad: Refer to

BR-16, "BRAKE PAD : Inspection and Adjustment"

.

- Rear disc rotor: Refer to

BR-16, "DISC ROTOR : Inspection and Adjustment"

Precautions for Removing Battery Terminal

INFOID:0000000009973036

• When removing the 12V battery terminal, turn OFF the ignition

switch and wait at least 30 seconds.

NOTE:

ECU may be active for several tens of seconds after the ignition

switch is turned OFF. If the battery terminal is removed before ECU

stops, then a DTC detection error or ECU data corruption may

occur.

• For vehicles with the 2-batteries, be sure to connect the main bat-

tery and the sub battery before turning ON the ignition switch.

NOTE:

If the ignition switch is turned ON with any one of the terminals of

main battery and sub battery disconnected, then DTC may be

detected.

• After installing the 12V battery, always check "Self Diagnosis Result" of all ECUs and erase DTC.

NOTE:

The removal of 12V battery may cause a DTC detection error.

JPFIA0001ZZ

SEF289H