Nissan Cube. Manual - part 946

TM-40

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F94R]

TRANSAXLE ASSEMBLY

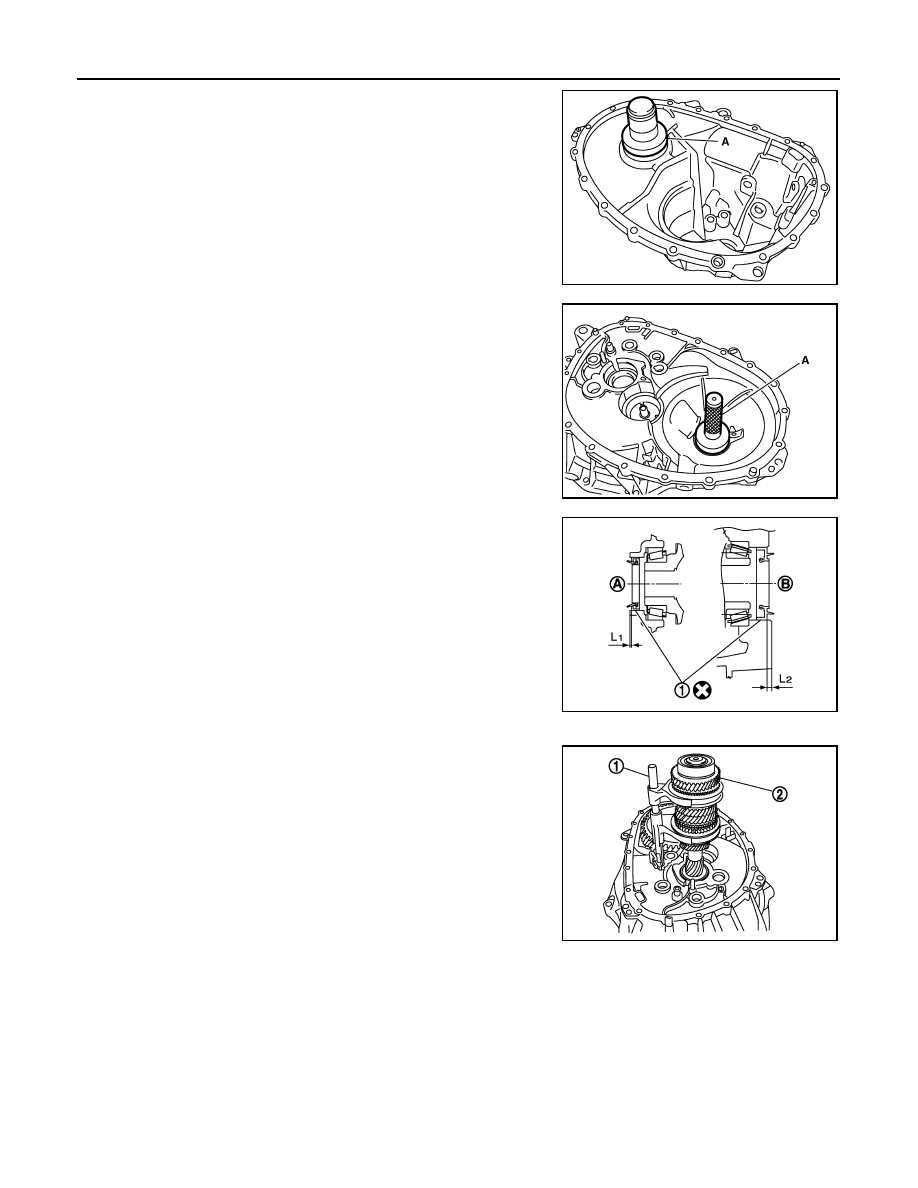

17. Install differential side bearing outer race (transaxle case side)

to transaxle case, using the drift (A) [SST: ST33400001 (J-

26082)].

CAUTION:

Replace differential side bearing outer race (transaxle case

side) and differential side bearing inner race (transaxle case

side) as a set.

18. Install differential side bearing outer race (clutch housing side) to

clutch housing, using the drift (A) [SST: KV38100200 ( - )].

CAUTION:

Replace differential side bearing outer race (clutch housing

side) and differential side bearing inner race (clutch hous-

ing side) as a set.

19. Install differential side oil seals (1) to clutch housing and tran-

saxle case, using the drift [Stamping number: B.vi 1666-B] of the

drift set [SST: KV32500QAA ( - )].

20. Install magnet to clutch housing.

21. Install final drive assembly to clutch housing.

22. Set fork rod (1) to input shaft assembly (2), and then install them

to clutch housing.

PCIB1726E

PCIB1722E

A

: Transaxle case side

B

: Clutch housing side

Dimension “L

1

”

: 1.2 – 1.8 mm (0.047 – 0.071 in)

Dimension “L

2

”

: 2.7 – 3.3 mm (0.106 – 0.130 in)

JPDIC0454ZZ

JPDIC0608ZZ