Nissan Cube. Manual - part 656

OIL PUMP

LU-13

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

Removal and Installation

INFOID:0000000009950384

REMOVAL

1.

Remove oil pan (lower). Refer to

2.

Remove front cover, and other related parts. Refer to

3.

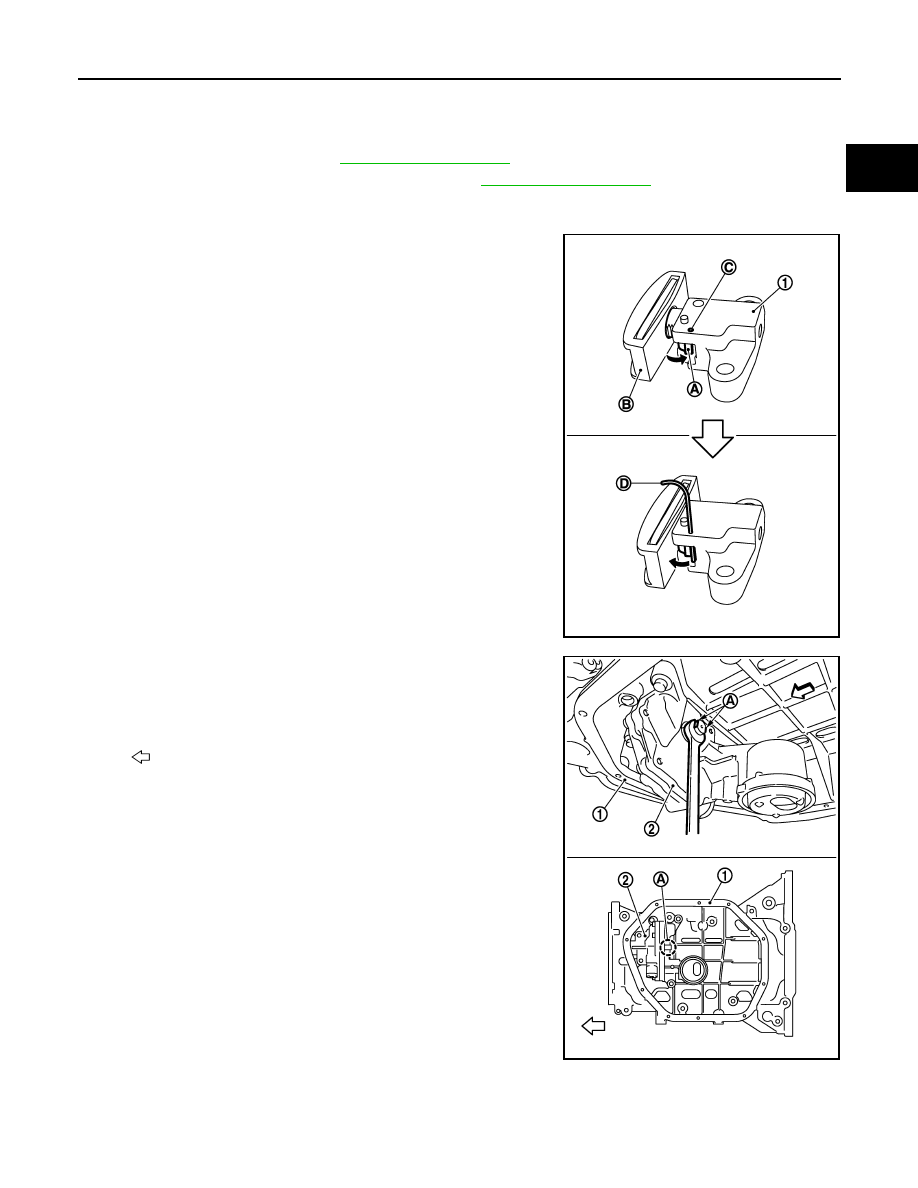

Remove oil pump sprocket with the following procedure:

• Add matching mark if necessary for easier installation.

a.

Press stopper tab (A) in the direction shown in the figure to push

the oil pump chain tensioner slack guide (B) toward oil pump

chain tensioner (1).

• The oil pump chain tensioner slack guide is released by press-

ing the stopper tab. As the result, the oil pump chain tensioner

slack guide can be moved.

b.

Insert a stopper pin (D) into tensioner body hole (C) to secure

the oil pump chain tensioner slack guide.

NOTE:

Use a hard metal pin with the diameter of approximately 1.2 mm

(0.047 in) as a stopper pin.

c.

Remove oil pump chain tensioner.

• When the holes on lever and tensioner body cannot be

aligned, align these holes by slightly moving the oil pump

chain tensioner slack guide.

d.

Hold the WAF part of oil pump shaft [WAF: 10 mm (0.39 in)] (A),

and then loosen the oil pump sprocket bolt and remove it.

CAUTION:

• Secure the oil pump shaft with the WAF part.

• Never loosen the oil pump sprocket bolt by tightening the

oil pump drive chain.

e.

Remove oil pump sprocket.

4.

Remove oil pump.

PBIC5314E

1

: Oil pan (upper)

2

: Oil pump

: Engine front

PBIC3539J