Nissan Cube. Manual - part 398

EC-478

< PERIODIC MAINTENANCE >

[MR18DE]

FUEL PRESSURE

PERIODIC MAINTENANCE

FUEL PRESSURE

Inspection

INFOID:0000000009947591

FUEL PRESSURE RELEASE

With CONSULT

1.

Turn ignition switch ON.

2.

Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT” mode with CONSULT.

3.

Start engine.

4.

After engine stalls, crank it two or three times to release all fuel pressure.

5.

Turn ignition switch OFF.

Without CONSULT

1.

Remove fuel pump fuse located in IPDM E/R.

2.

Start engine.

3.

After engine stalls, crank it two or three times to release all fuel pressure.

4.

Turn ignition switch OFF.

5.

Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

CAUTION:

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

• Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel

pressure cannot be completely released because this models do not have fuel return system.

• The fuel hose connection method used when taking fuel pressure check must not be used for other

purposes.

• Be careful not to scratch or put debris around connection area when servicing, so that the quick

connector maintains seal ability with O-rings inside.

• Do not perform fuel pressure check with electrical systems operating (i.e. lights, rear defogger, A/C,

etc.) Fuel pressure gauge may indicate false readings due to varying engine load and changes in

manifold vacuum.

1.

Release fuel pressure to zero. Refer to "FUEL PRESSURE RELEASE".

2.

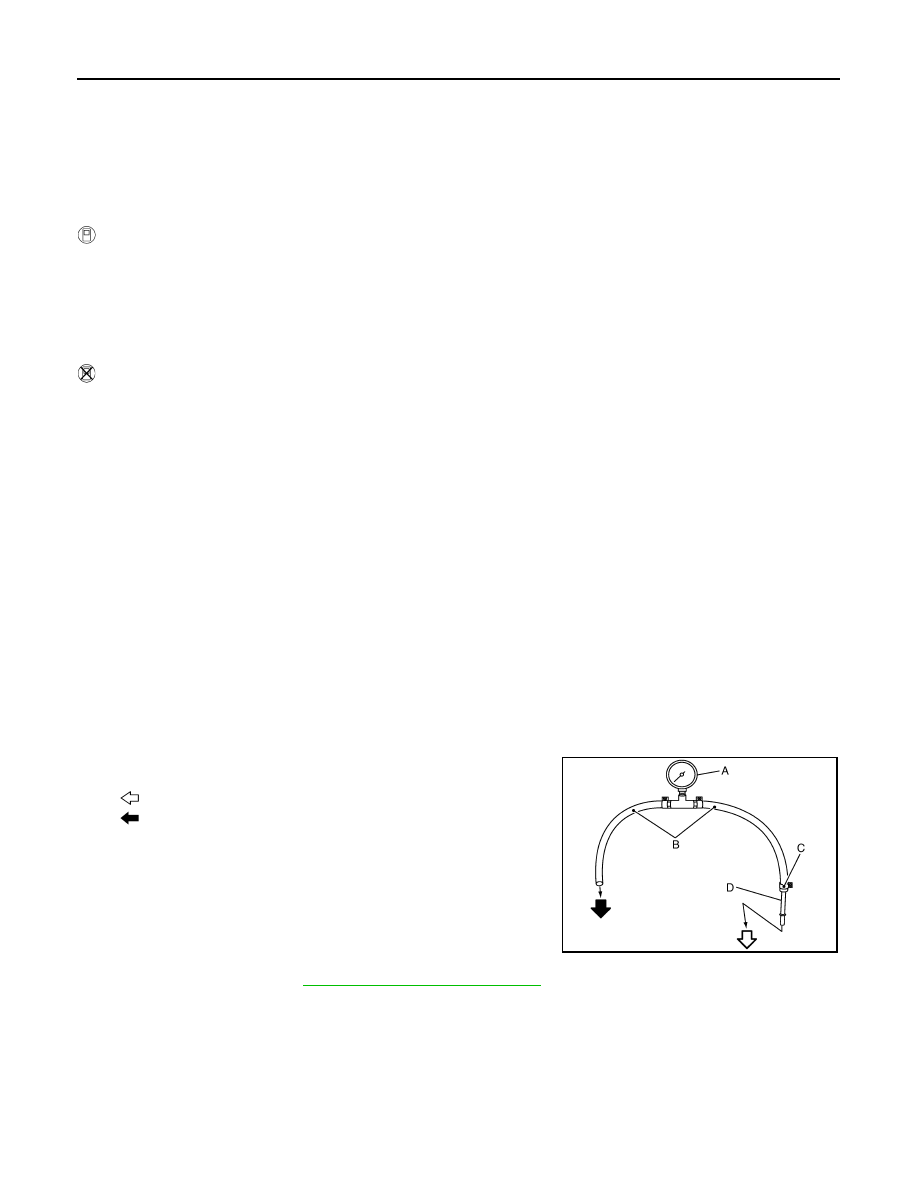

Prepare fuel hose for fuel pressure check B and fuel tube

adapter (KV10118400) D, then connect fuel pressure gauge A.

•

: To quick connector

•

: To fuel tube (engine side)

• C: Clamp

• Use suitable fuel hose for fuel pressure check (genuine NIS-

SAN fuel hose without quick connector).

• To avoid unnecessary force or tension to hose, use moder-

ately long fuel hose for fuel pressure check.

• Do not use the fuel hose for checking fuel pressure with dam-

age or cracks on it.

• Use Pressure Gauge to check fuel pressure.

3.

EM-35, "Removal and Installation"

.

• Do not twist or kink fuel hose because it is plastic hose.

PBIB2982E